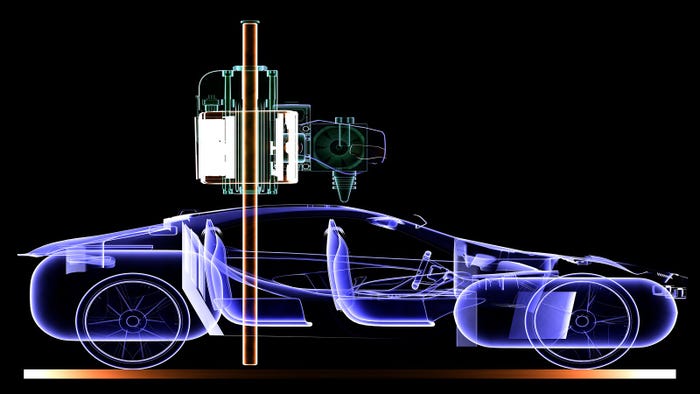

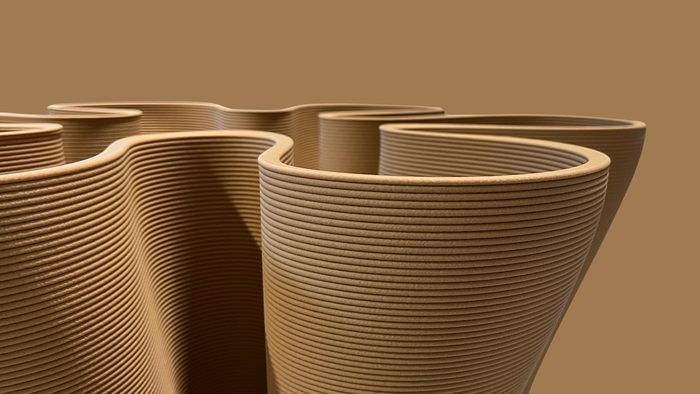

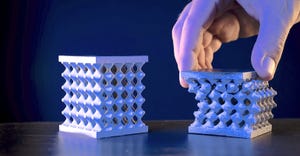

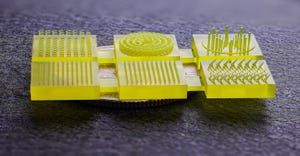

3D-Printing Materials

New 3DP printers

3D Printing

Materialise Introduces New 3D Printing Materials and More 3DP NewsMaterialise Introduces New 3D Printing Materials and More 3DP News

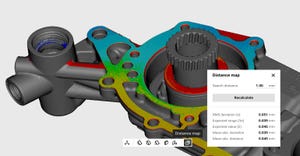

We’re also looking at a new IDTechEx 3DP market analysis report and new 3D printing software from HP.

Sign up for the Design News Daily newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)