Why Patrick Mahomes’s Helmet Shattered on National TV

The Kansas City quarterback and NFL MVP smashed his helmet in a goal line collision.

The images of Kansas City Chiefs quarterback Patrick Mahomes’s helmet breaking apart on live television during the broadcast of the NFL playoff game between the Chiefs and the Miami Dolphins were a shock to viewers.

Mahomes leaned into a collision with Miami safety DeShon Elliott and a big chunk of red plastic flew conspicuously from Mahomes’s helmet. Believe it or not, this was not necessarily a bad outcome.

“Just because it broke doesn’t mean it didn’t do its job,” observed Virginia Tech Helmet Lab director of outreach Barry Miller, PhD. Here’s why:

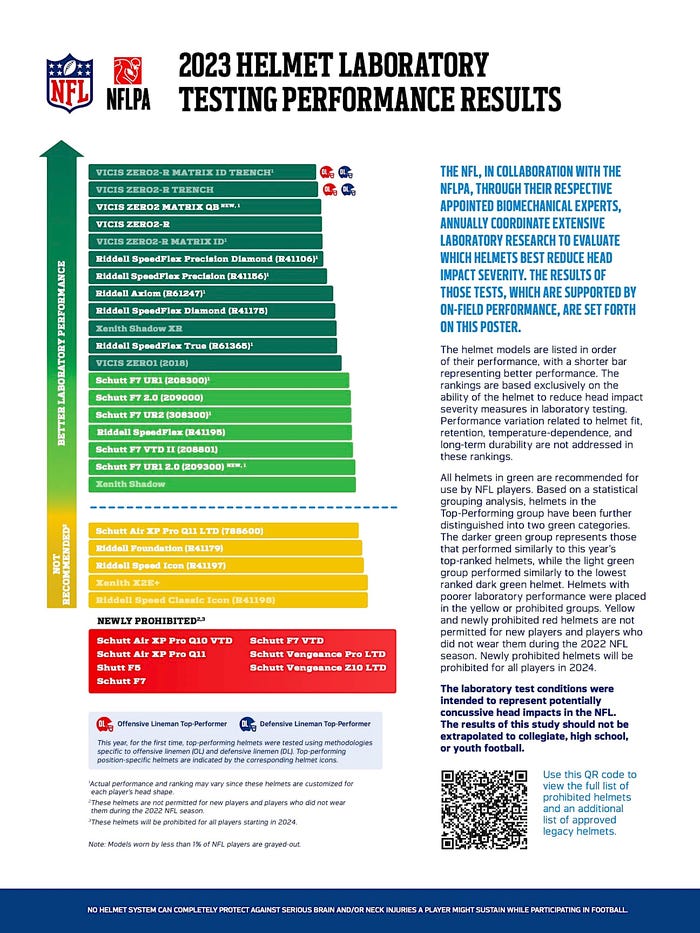

Mahomes was wearing the Vicis (pronounced “vice-is”) Zero2 helmet, which is designed to cushion impacts with a soft deformable polycarbonate outer layer. He has struggled with concussions and Vicis helmets top the ratings by both the National Football League and the Virginia Tech Helmet Lab, so this innovative helmet is a natural for Mahomes.

Vicis explains on its website: “Flexible outer shell technology, exclusive to Vicis helmets, allows the Zero2 to respond like no other helmet on the market. By deforming like a car bumper, impact forces are absorbed at the point of contact, before they reach the head. The result is not only groundbreaking protection, but a helmet that feels like no other.”

Car bumpers, it is worth noting, are sacrificial equipment, designed to absorb damage themselves rather than passing impact forces to vehicle occupants. That’s the situation here too. “You want the helmet to absorb energy like the crumple zone in the car to increase impact duration and reduce peak acceleration numbers to your head,” said Miller.

Mahomes's Vicis Zero2 helmet has distinctive vent holes along the sides. JAMIE SQUIRE/GETTY IMAGES

In fact, bicycle helmets and others are designed to work like this. “Single-impact helmets are designed to crush, crumple, or crack under impact,” Miller pointed out. While football helmets generally last several seasons, having the helmet sacrifice itself to protect the wearer is a satisfactory outcome.

This failure seems to have surely been caused by the extremely cold temperatures at game time, which was reported by NBC broadcasters as -4 degrees F. “I’m sure it had to do with it being really cold,” Mahomes mused during his post-game press conference.

That is the conclusion by Vicis too. “Extreme conditions like those experienced in Saturday evening’s NFL playoff game are bound to test the limits of even the highest performing products,” said Vicis parent company Certor Sports in a statement. “While outer shell damage is not ideal, the Zero2 helmet did its job of protecting Patrick Mahomes during a head-to-head impact in unprecedented cold temperatures.”

NATIONAL FOOTBALL LEAGUE

Without examining the helmet it is probably impossible to diagnose the cause of the failure with certainty, but “material-wise, cold is not really good for pliability,” Miller observed.

For impact testing under the National Operating Committee on Standards for Athletic Equipment “Standard Performance Specification for Newly Manufactured Football Helmets” (ND)002-17m21 is conducted using four helmets; two on the drop test and two on the pneumatic ram test. One of each of those tests is done at an unspecified ambient temperature, while a second High-Temperature test uses helmets that have been heat-soaked at 100 degrees F for 24 hours. There is no Low-Temperature test.

It turns out that lab tests aren’t the only time that cold temperatures need to be considered. The Chiefs apparently had Mahomes’s spare helmet lying on the team bench, where it cooled to the ambient temperature. While there were heaters on the sideline for players, the temperature where the helmet was stored was still freezing. This caused problems for Mahomes when he went to the backup.

“We’ve got to talk about where we store the backup,” Mahomes declared. “It was like frozen. So when I tried to put it on it was completely frozen. I couldn’t get it on. We were able to adjust it on the sideline get it kind of warmed up a little bit and get rolling from there.”

Mahomes's problem wasn’t only that the cold helmet chilled his noggin uncomfortably. The real issue was that the Vicis helmet’s multiple layers of pliable material that are designed to move into the best position to fit the wearer and cushion impacts were frozen in place. That means that the pads meant to give way to provide a comfortable fit did not move.

Here’s how the Vicis helmet is supposed to work at normal temperatures: Beneath the deformable (sometimes catastrophically so, in cold temperatures!) outer shell, Vicis helmets employ the Vicis RFLX 2.0 system of buckling column structures that connect the outer shell with the helmet’s inner shell. These columns provide impact performance with minimal mass, letting Vicis engineers place them strategically to tune impact performance in key locations.

The inner shell is a pretty straightforward polycarbonate shell, but Vicis says that the shape has been carefully designed using data from hundreds of different head shapes for an optimal design that fits a wide range of players.

Inside that inner shell, Vicis uses what it terms the DLTA pod system. These pods are interchangeable pads mounted in six locations on the inner shell to further customize the helmet’s fit to the wearer’s head.

These pads are not the traditional foam padding of the Dark Ages. Instead, they are 3D-printed resin lattices from Carbon, a Redwood City, Cal. additive manufacturing specialist. “When I first saw Carbon, I lost my mind,” said Vicis test engineer John Ward in a YouTube video testimonial for Carbon.

“I thought that was the coolest thing ever,” he said. “You could actually take this part, 3-D print it in whatever crazy geometry you come up with because it is a lot more flexible than traditional machining, stick it in a helmet, test it, and get repeatable results! So much so that we can actually put it on a player on the field. It is mind-blowing! It still is mind-blowing. I can’t believe that we’re doing this.”

The lattice is made using an energy-damping dual-cure resign that Carbon calls EPU 45. “EPU 45 is a strain rate-sensitive material, making it ideal for highly breathable lattice geometries tuned for comfort at low impact speeds and energy absorption at high impact speeds,” said Carbon senior product development manager Leah Heist.

Vicis finishes the Zero2 helmet with one of eight different facemask designs, available in either steel or titanium, depending on the buyer’s budget.

Will those buyers be concerned by the breakage of Mahomes’ helmet? Probably not, said Virginia Tech’s Miller, because they understand the circumstances of the event. “The football helmet consumer is pretty savvy,” he said. They have to be, he continued, because the products are getting so sophisticated. “Football helmets are the most advanced sports helmets on the market, by far,” Miller said. The Vicis Zero2 certainly provides a solid case for that statement, even with this high-profile incident.

About the Author(s)

You May Also Like