Gadget Freak

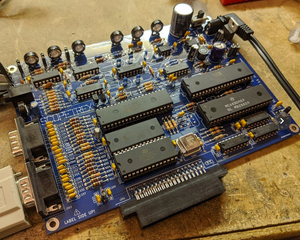

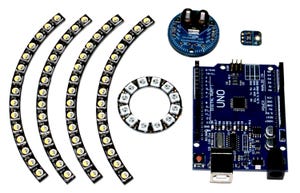

AI joins forces with computer DIYer.

Electronics

Can AI Help Revive an Old Computer?Can AI Help Revive an Old Computer?

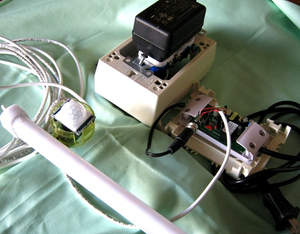

Watch this DIYer use ChatGPT to try to help her repair a non-working Commodore 64.

Sign up for the Design News Daily newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)