What Has and Hasn't Changed in the Basic Design of Robots? You May Be Surprised

Designing robots was always a task that required a variety of skills. Today's design approach has a few new twists and turns.

March 7, 2024

At a Glance

- Make sure you understand the basics of robot design as well as the robotic engineering lifecycle process

- Consider your options for electromechanical design and programming

- New trends include the use of AI and edge computing as well as mobility and miniaturization

Over the last several decades, the design of robots has moved from an academic exercise and the domain of deep-pocketed corporations to the world of start-ups, hobbyists, and everyday people. Customized and modular platforms like LEGO Mindstorm, Maker, numerous Arduino-based platforms, and hundreds more are available to beginners. Conversely, professional engineers can use any number of CAD-based design and simulation systems to aid in developing more complex industrial robots.

Regardless of the ease or difficulty in designing a robot, two things remain constant: the skills needed and the basic lifecycle development process. The following article will cover each topic briefly and its relevance today.

Robot Design From Then to Now

The design of robots has come a long way since their start in the 1960s when their main application was on the factory floor. During the last decade, factory robots—known as collaborative robots or cobots—have advanced to work side-by-side with humans, typically in manufacturing environments. Developing collaborative robots requires creating many complex systems to sense, communicate, and move alongside humans safely and effectively.

In the very near future, robots will be designed and taught to do tasks with the addition of artificial intelligence (AI) technologies. Incorporating AI into robotics significantly increases automation capabilities in production, innovation, and cost effectiveness. The addition of this technology is quite a change from past automation improvements, which allowed robots to replace mundane, well-understood, and very repetitive tasks.

Robots have moved beyond the manufacturing floor to almost every other industry. But one of the critical robotic trends that transcended all markets is mobility, which combines technologies from all key sectors like sensors, actuators, embedded vision, AI markets, edge computing, and more. Implementation of robotic mobility is growing on the manufacturing floor, in hospitals, and home care across the ground, air, and water.

Today's mobile robots thrive in a multitude of environments and applications. Fleets of mobile robots with computer vision-based navigation now deliver food orders across major universities. Mobile robots in manufacturing environments are becoming a more common choice for tasks such as materials transport and machine loading and unloading. Underwater robots are going places where few humans could survive, like the ocean's depths, to drones flying into massive forest fires to collect vital data. Mobile robots are even walking on the ceiling of homes to bring needed services while avoiding furniture and floor clutter.

Rendering of robots delivering food in restaurants. Oselote/iStock/Getty Images Plus via Getty Images

Outside of the factory and warehouse floors, human-friendly cobots are finding acceptance in the medical and hospital halls. In addition to their gentleness, these mobile robots can't be infected by viruses like COVID-19. Robotic systems, such as disease prevention, diagnosis and screening, and patient care, have been essential in clinical care.

Whatever the application, from life-saving services to unique toys like drones, the process of designing a robot remains the same.

Basic Robot Design

Before you start designing your robot, you need to understand what problem it will solve. What type of robot is necessary? Will it be stationary or mobile? Will it interact directly with humans and other robots? Does it need to "see" things or have significant arm motion? These are a few high-level questions that should be considered at the beginning of the design process.

Designing a modern robot requires at least a working knowledge of electromechanical (or mechatronic) systems, i.e., the collaborative, integrated development of electronic/electrical and mechanical components to perform the needed functions while meeting the overall requirements. Prototyping and simulation via CAD tools are often required for an optimal design.

A big trend in electromechanical systems is miniaturizing all electric/electrical and mechanical components. The shrinking size of chips has enabled the miniaturization of boards and other systems, which is why smartphones, wearables, and even automotive vehicles have become smaller and more compact. Mechanical miniaturization has resulted in small actuators, gears, and motors—some so small they can easily fit inside the human body. The benefits of miniaturization are being enjoyed across many different fields of application, from sensors, wearables, and medical devices to satellites, drones, and even video games.

A mini drone. ajcespedes/iStock/Getty Images Plus via Getty Images

Let's consider the various electromechanical engineering disciplines that affect robotic design.

Mechanical Design

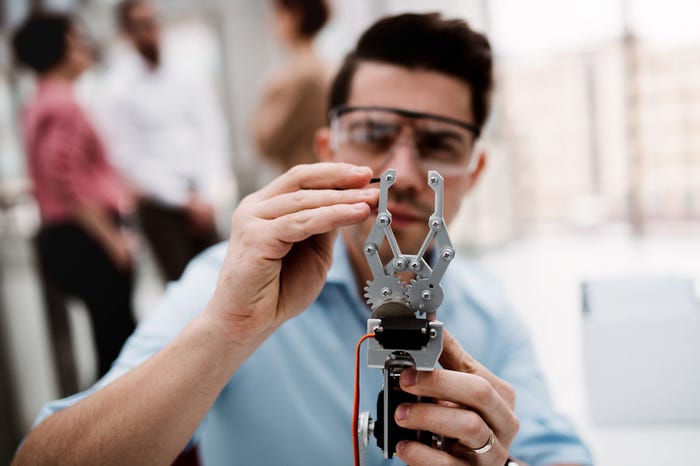

Most of today's robots require motion; thus, mechanical design skills specifically focused on motors (mostly DC), gears, and actuators are essential. A hardware prototype is often needed to ensure all components work together as planned.

One of the biggest challenges for mobile robots is balancing, especially if they are to carry a load. Gyros can be used to determine orientation, that is, to measure a rotation from a balanced position that can determine adjustments to maintain uprightness. Robot balance can be achieved with old-school analog, mechanically spinning tops or with newer technologies to determine the angular rate, such as ring laser gyros or tiny microelectromechanical system (MEMS)-based gyros that use vibrating structures of small, resonating, mass sensors to detect shifts in angular velocity.

A robust design for robotic linear motion would include an array of complementary inertial sensors to measure motion in as many ways as possible, e.g., accelerometers, gyros, and even magnetometers. Inertial measurement units (IMUs) typically provide six degrees of freedom, meaning that they contain three accelerometers—one for each of the three physical coordinates (x, y, and z)—plus three gyroscopes for each axis. In IMUs, the number of degrees of freedom is the number of available independent readings. Some of the latest IMUs have nine degrees of freedom, adding three magnetometers to the existing inertial-sensor mix.

Electronic Design

Unless you're nostalgic for steampunk robots that use mainly mechanical systems, you must include electronics in your designs. For example, while mechanical actuators are the muscles of a robot, the most popular actuators consist of electric motors that rotate a wheel or gear. Thus, an understanding of electronics and microcontroller-based motors, components, and power is needed to design mechanical subsystems.

To control the mechanical performance of a robot, electronics are needed to process data from many sensor inputs and decide what action to take. Specifically, sensors give information about the environment or the robot itself, e.g., the position of its arms, legs, end effectors, and the like. After processing this information, the robot sends (either wired or wirelessly) the calculated signals to the actuators (motors), which move the mechanical structure to achieve the required coordinated motion.

Robots need electronics to understand and act on data collected by sensors and to support a CPU. PhonlamaiPhoto/iStock/Getty Images Plus via Getty Images

Electronics also act as a robot's CPU-based brain, processing sensor data, making decisions, executing instructions, and coordinating the interaction of various components of the robot's hardware and software systems. This crucial component has revolutionized the field of robotics, enabling machines to perform tasks autonomously and with increasing complexity.

Of course, the CPU relies on software programs to provide instructions and algorithms for the robot's operation. These programs are typically developed by robotics engineers and programmers who work closely with the hardware designers to ensure integration between the CPU and the robot's other components.

Programming

A CPU for a brain does little good without code to go with it. Once the electronics are in place, the microprocessor or microcontroller system must be programmed to know how to act and interface with the surrounding world. While microcontrollers are generally used for more repetitive tasks, microprocessors enable advanced tasks such as image processing, artificial intelligence, mapping, and path planning. The top robotic programming languages are C/C++ and Python and are used to do everything from the motor function of a robotic arm to AI functionality.

Python is relatively easy to use as it contains a selection of libraries to implement the essential robotic function. Using coded libraries often means fewer lines of code are required, making Python faster and easier to use than traditional C/C++. Python reduces programming time by eliminating the need to define and cast variable types and allowing motions to be coded in the same script. Python's popularity means it has a large community of developers to provide help and guidance. To learn more, see "Basics of the Python Programming Environment."

For a simple robot, you'll need a basic understanding of coding, but you don't have to be a pro. Often, you can copy and paste code from the Internet as long as the code is compatible with the robot hardware and firmware. But be careful that the copied code is from a reliable source and free of viruses or destructive structures.

Prototype or Production

One additional consideration in designing an electromechanical wonder is whether it's a prototype—sometimes known as a proof-of-concept (one-of-a-kind)—or something that will be mass-produced. These aren't mutually exclusive choices, as a prototype might well lead to a production run, but it helps to know the difference since it will affect your choice of materials and design alternatives.

The decision to make one unique or many commercial robots will also affect the machine's look, feel, and fabrication. The enclosure of the robot is determined by the robot's functionality and the purpose it serves. While enclosures are needed to protect interior components like actuators, gears, and electronics from environmental concerns, engineers can also use enclosures to give the robot personality and create a suitable interface between humans and other robots.

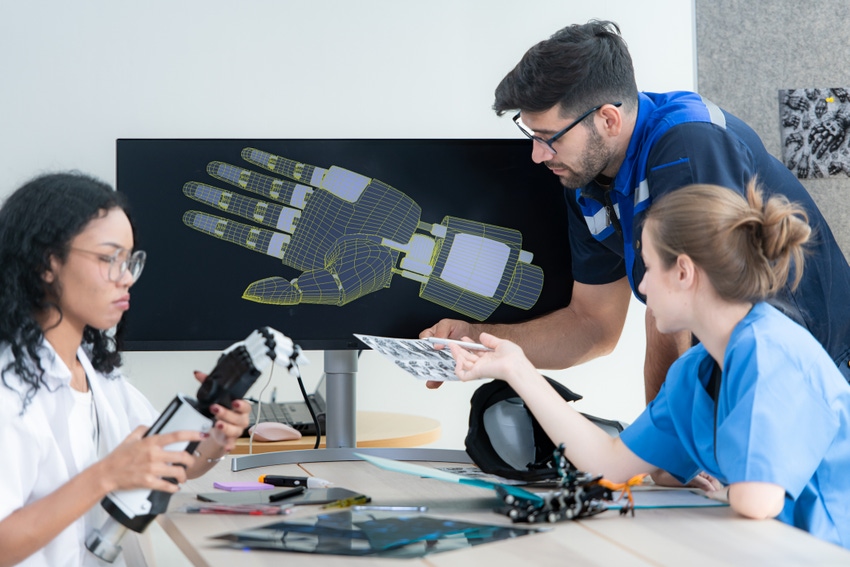

Robot designers should have an understanding of electromechanical (or mechatronic) systems, electronics, and programming. Halfpoint/iStock/Getty Images Plus via Getty Images

Robotic Engineering Lifecycle Process

Once you understand the different engineering technologies involved in making a complete robot, it's important to understand the development process. Since creating a robot requires a variety of engineering disciplines—electronics, mechanical, and computer science, to name a few—it already closely follows the basic lifecycle process, as outlined below.

1. Define the Problem

First, you must determine the purpose and design of the robot and write down the requirements, from a high level to specifics. For example, a robot might need to move among humans, which leads to interface and safety requirements. The robot must move at a safe speed when moving around humans. Thus, it must be aware of humans and respond to their changing positions. All the requirements should be documented for the design activities and to later prove they were met via a verification and validation process.

2. Solution Architectures

Once you have a reasonable set of high-level requirements, you can begin to lay out the robot's functionality, leading to the assignment of initial hardware and solution architectures. For example, for a robot to move, it will need specific mechanical components controlled by software. How will the robot's subsystems, i.e., the different arms and legs, be directed at a system level? How much power will all the systems require, and at what cost?

As the robot's overall functionality is better understood, more details will need to be considered, such as determining the requirements of specific actuators, motors, sensors, and batteries/power supplies for the design. Based on the detailed functions the robot must perform, you may need to design subsystem vision sensors and proximity-detecting sensors, perhaps based on ultrasonic, infrared, and even fiber optic cable-based sensors.

3. Design Alternatives and Tradeoffs

In addition to technical requirements and functionality, consider cost and time issues. Sometimes, building a prototype will help answer questions about which functions should be implemented in hardware versus software to meet requirements, functionality, and time schedules and remain within budget.

To determine the optimal balance among competing design alternatives, it's important to remember factors such as the environment, power, sensor selection, and overall fabrication issues, among other considerations.

Unless the robot is stationary, the environment in which it must operate will be a significant consideration. What terrain will it need to navigate, from a hospital corridor or trade show floor to a manufacturing or warehouse facility to roaming around a distant moon or planet? What environmental conditions must it withstand, such as dust, humidity, vibration, and water intrusion? The environment will dictate the types of sensors (e.g., acoustic versus laser-based) required and their ruggedness.

Other robotic requirements, such as motion, will also determine sensor selection. Generally, a proximity subsystem will be a part of any design to detect objects with which the robot must avoid or interact—as with humans or a control panel. Many types of proximity sensors are based on many different technologies, such as embedded vision cameras, ultrasonic devices, laser-based lidar, and others. The selection of sensors must also be balanced with all the different kinds of information the robot needs to acquire from the physical environment and how it will be processed – which is related to the processing power of the CPU electronics.

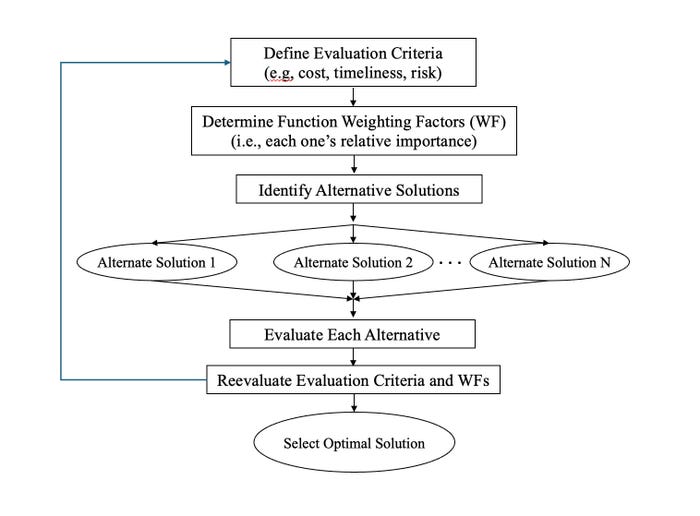

The resulting environmental and sensor requirements must be balanced against the power and cost requirements of the overall robot. Selecting the most appropriate solution from a host of competing alternatives is not an easy task. Engineers typically use trade studies, or tradeoff analysis, to logically evaluate alternative solutions' relative merits. A trade study is a formal process in which two or more competing alternative solutions are compared regarding technical attributes, risk, cost, schedule, and other concerns.

Typical technical trade study process. JOHN BLYLER/JB SYSTEMS TECH

Power is another major constraint on the design of a robot. Will it require batteries to operate, or must it be tethered to a wall for power? Every system component needs power, so an overall power requirement must be determined. Time is also a consideration here since some components will need more power at different times, e.g., if a robotic arm is lifting a heavy object.

Power consumption is a critical component of any electromechanical system that must be considered at the very start of the design. The selection of all electronic and electrical components must always consider the system's overall power requirements. If too little power is available, then parts won't work. If too much, the power systems are overdesigned, thus wasting cost and efficiency.

Another common tradeoff consideration is the weight and shape of the system. How much will the robot weigh, and is there a weight restriction? Is there a limit to the robot's size (especially height)? If it's too tall, will it be unstable as it turns a corner during motion? One potential solution is to use miniaturized components to reduce the weight and shape of the system, but how will the cost and overall functionality be affected? One or more trade studies will answer this question, but best practices suggest that flexibility is critical in design. One unusual example of flexibility is the design of a robot cat-like tail for astronauts to help maintain their balance in weightless space. (See How to Build Your Robotic Tail.)

Building hardware prototypes and coding rapid software prototypes will help answer tradeoff analysis questions and determine the best way to meet requirements and time schedules and remain within budget.

4. Implement the Solution in Hardware and Software

The fourth step to developing a robot is to build and program your hardware subsystems and needed data processing. All parts, such as the frame, the sensors, the motors, cables, and the batteries or wall outlet plug, must be assembled. You will need to upload the required code that will control the behavior and logic of your robot, such as the movement, collision avoidance, performing specific tasks (like lifting an object), and relaying information to others. Many programming platforms are available, such as Arduino, Raspberry Pi, or LEGO Mindstorms, as well as more CAD-based professional tools.

5. Test, Verification, and Validation

Testing, verification, and validation techniques and processes are used to ensure that you've actually met all of the requirements in the robotic system design. What is the difference between these three terms?

When you test, you ensure the product or system works, but only after you have built or acquired the product components, chips, boards, packages, and subsystems.

When you verify, you ensure the product or system works before it has been created or manufactured. In systems engineering, you must ensure that your design meets the requirements. In this way, verification is a form of testing, but verification tends to be trickier as you test something before the product exists, whether in software or hardware.

Finally, validation checks whether the specification captures the customer's intentions, while verification checks that the system or components meet specifications.

As the robot is being built and assembled, it's necessary to make sure it works as intended and meets the requirements and constraints you defined in the first step. You need to use different methods, such as observation, measurement, and simulation, to collect data and analyze the performance and effectiveness of your robotic system. Any hardware failures or coding errors, bugs, and issues must be documented and resolved.

Even the prototypes need to be tested, e.g., the early breadboards upon which the initial programming was begun. All sensors, motors, actuators, vision subsystems, and the like should be tested using the breadboard running the necessary code and drivers.

Once the subsystems have been tested and verified, everything should be mounted and secured upon the robot's structural frame and chassis. Plenty of third-party vendors provide robotic chassis, but you may need to build one yourself—depending on the robot's required functionality.

6. System Test and Operation

By now, you should have a finished robot, but some final adjustments to the hardware and updates to the software may still be needed. Further, if requirements for the final system have changed significantly, you may need to consider major redesigns, but hopefully, that won't be the case. Still, although your robot is now complete and finalized, be open to making any adjustments for continuous improvement. You may find that you need extra sensors or that the power consumption is too high.

Times Have Changed—Building a Robot Today

While the basic development process remains the same, the design tool suites for robotics have changed in the last 20 years. In the past, designing a robot was a very complex process requiring engineers to deal with the interdependencies between the system's physical structure, sensory and motor layouts, and behavior. As discussed in the previous section, every development detail was done manually, requiring months or years of iterative designing, prototyping, and testing. Simulation has undoubtedly helped, but requires lots of computing horsepower and special skills.

Though nascent technology, AI systems are poised to significantly aid humans in designing their megatronic counterparts. For example, rather than assume a particular anatomical form for a proposed robot, AI-based design aids consider the functional requirements to discover potentially new ways to implement mechanical motion. This approach promises faster design, manufacturing, deployment processes, and unique robotic designs.

On the software development side, generative AI enables low- and even no-code creation. Tools like ChatGPT can generate reasonably functional code on demand. This technology is also used in embedded vision and sensor-based markets, e.g., to improve robot vacuum cleaners and self-navigation drones. Here's a clip of a team led by Northwestern University researchers that has developed the first artificial intelligence (AI) to date that can intelligently design robots from scratch.

Skills Needed for Robotics

As you may have guessed, the development of robots can require various skills, including knowledge of electronics, mechanical design, and software programming. If working on a team project, the ideal developer will be a system-of-systems engineer who can communicate effectively with many different engineering disciplines and project management.

Still, having specialized knowledge and expertise will be a big plus, in areas such as software engineering, vision engineering, AI engineering, and electromechanical (mechatronic) engineering.

While the design of a robotic system can be complex and time-consuming, the results are changing the world around us, and usually for the better.

About the Author(s)

You May Also Like