Gadget Freak

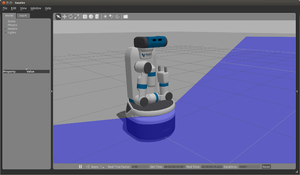

AI hardware assistants leave a lot to be desired.

Artificial Intelligence

Should You Opt For An AI Hardware Assistant?Should You Opt For An AI Hardware Assistant?

These devices can provide instant AI-generated feedback, but does that convenience justify their added price and poor repairability?

Sign up for the Design News Daily newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)