Motion Control

thumbnail

Sponsored Content

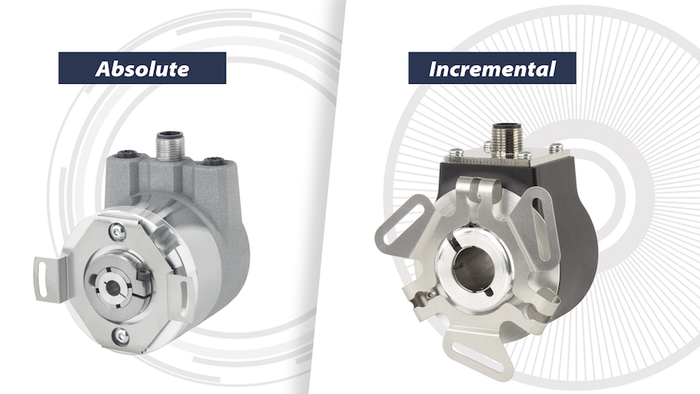

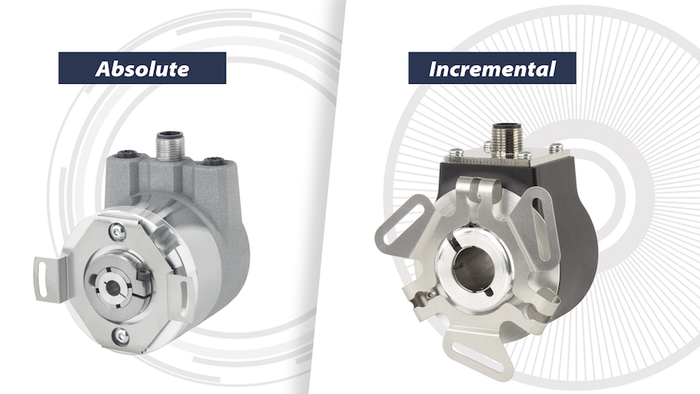

Absolute vs. Incremental Rotary Encoders: Which is Best?Absolute vs. Incremental Rotary Encoders: Which is Best?

Both types of rotary encoders provide motion sensing and feedback about a rotating shaft. Knowing their differences will help you choose the right type for your needs.

Sign up for the Design News Daily newsletter.

.jpg?width=700&auto=webp&quality=80&disable=upscale)