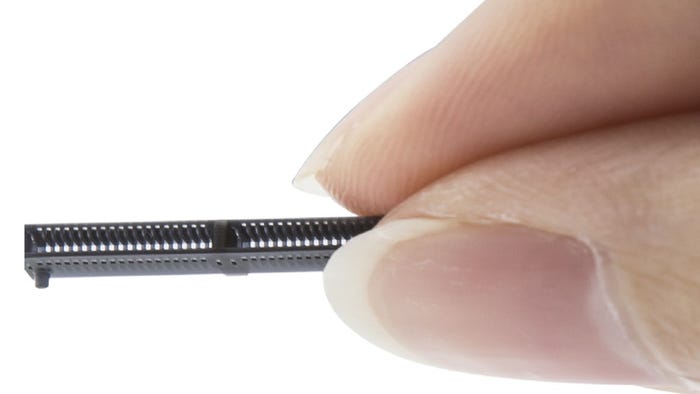

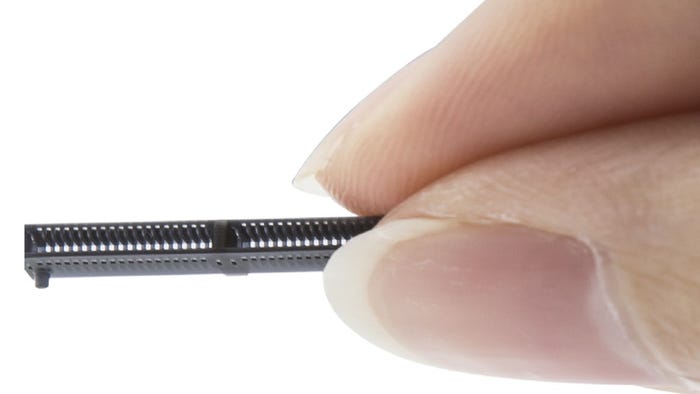

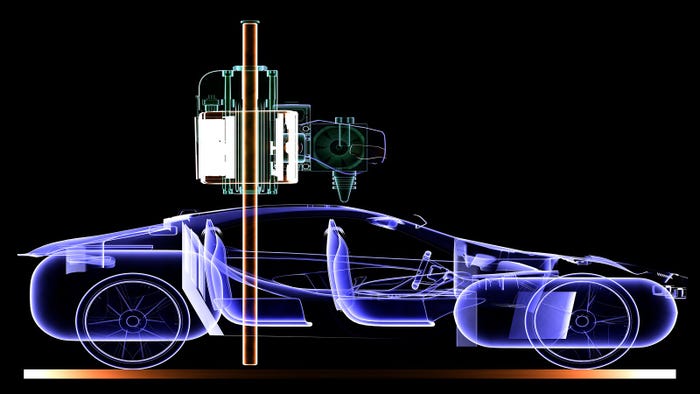

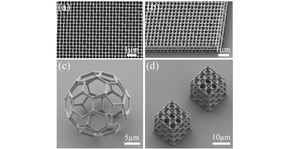

3D printed micro parts

3D Printing

Industry Voices: Is Micro-3D Printing the Future for Tiny Parts?Industry Voices: Is Micro-3D Printing the Future for Tiny Parts?

Additive manufacturing is becoming an efficient and cost-effective alternative to traditional micro-manufacturing methods such as molding.

Sign up for the Design News Daily newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)