Self-Heating Microfluidic Devices Could Bring Diagnostics to Under-Served Regions

A method for 3D printing inexpensive mini chemical reactors requires just a single process and precludes the need for expensive materials or manufacturing techniques.

January 25, 2024

Scientists have developed a method to facilitate the creation and replication of small microfluidic devices, creating an easier manufacturing process for a range of do-it-yourself medical diagnostic and testing devices such as COVID-19 tests.

The fabrication of self-heating microfluidic devices by 3D printing, achieved by researchers at MIT, also could extend the accessibility of these devices for regions of the world that are undeserved by formal medical facilities or professionals, such as developing countries, they said.

Microfluidics are miniaturized machines that manipulate fluids and facilitate chemical reactions and used to detect disease in tiny samples of blood or fluids. Typically, these applications require chemical reactions that must be performed at specific temperatures and thus require cleanrooms for manufacture. Further, the more complex of these devices use heating elements made from gold or platinum using processes that can be difficult to scale up.

The MIT team, however, used multimaterial 3D printing and a single, inexpensive manufacturing process—with materials costing only about $2—to create self-heating microfluidic devices with built-in heating elements. The devices come off the printer ready to use and can heat fluid to a specific temperature as it flows through microscopic channels inside the tiny machine.

"We can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods," said Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories (MTL) and one of the researchers on the project. "This is really a way to democratize this technology."

The technique that the researchers used also can be customized to create a device that heats fluid to a certain temperature provides a heating profile within a specific area of the device, expanding the devices' flexibility for use.

How They Did It With 3D Printing

The team used multimaterial extrusion 3D printing to create the device, a monolithic process that uses numerous nozzles to squirt different materials to build a device layer by layer. In this case, two materials were used—a biodegradable polymer known as polylactic acid (PLA) that is commonly used in 3D printing and a modified version of PLA.

The modified PLA includes mixed copper nanoparticles, converting what's typically any insulating material into an electrical conductor, Velásquez-García said. Thus, when electrical current is fed into a resistor composed of the copper-doped PLA, it dissipates energy as heat.

“It is amazing when you think about it because the PLA material is a dielectric, but when you put in these nanoparticle impurities, it completely changes the physical properties," he explained. "This is something we don’t fully understand yet, but it happens and it is repeatable."

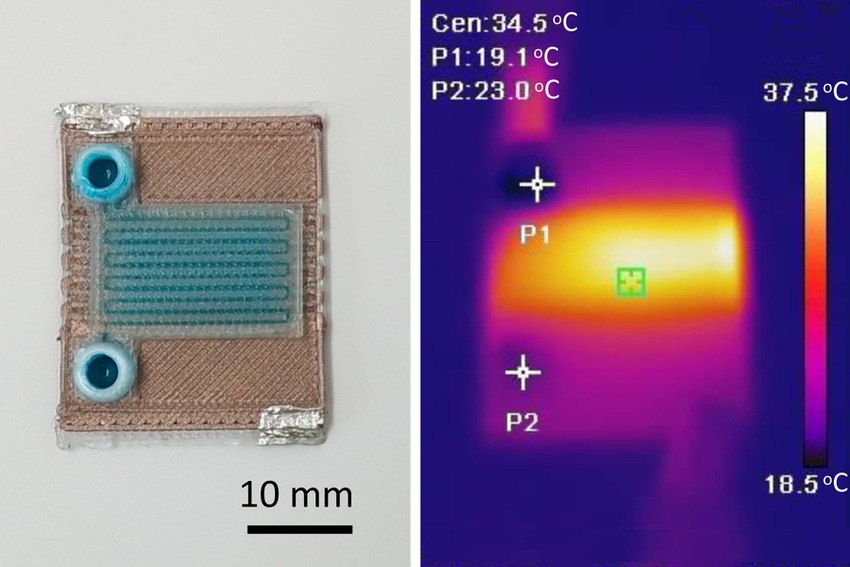

The researchers fabricated a heating resistor from the copper-doped PLA using a multimaterial 3D printer and then printed the U.S. quarter coin-sized microfluidic device, through which channels about 500 micrometers wide and 400 micrometers tall are threaded. These channels carry warm water heated by the heat dissipated from the resistor to facilitate chemical reactions.

Another aspect of the PLA material that affects the design is that it's translucent, so fluid in the device remains visible. This is different than other microfluidic processes, which often require light or visualization to observe what is happening during chemical reactions, Velásquez-García said.

Overcoming Current Limitations

Specifically, the device can heat fluid by 4 degrees Celsius as it flowed between the input and the output channels. It's also customizable, paving the way for devices that can heat fluids in certain patterns or along specific gradients.

“You can use these two materials to create chemical reactors that do exactly what you want," Velásquez-García said. "We can set up a particular heating profile while still having all the capabilities of the microfluidic.”

However, there is a limitation to the design in that PLA can only be heated to about 50 degrees Celsius before it starts to degrade, the researchers found. Many chemical reactions—including those used for polymerase chain reaction (PCR) tests—require temperatures of 90 degrees or higher. Further, to precisely control the temperature of the device, researchers would need to integrate a third material that enables temperature sensing.

The researchers plan to continue development on the design to tackle these limitations. Velásquez-García also aims to print magnets directly into the microfluidic device, which could enable chemical reactions that require particles to be sorted or aligned, he said.

The team also is exploring the use of other materials besides PLA that could allow for reactions that reach higher temperatures, and studying PLA to understand its conductivity when impurities are added to it, Velásquez-García said.

“If we can understand the mechanism that is related to the electrical conductivity of PLA, that would greatly enhance the capability of these devices, but it is going to be a lot harder to solve than some other engineering problems,” he said.

About the Author(s)

You May Also Like