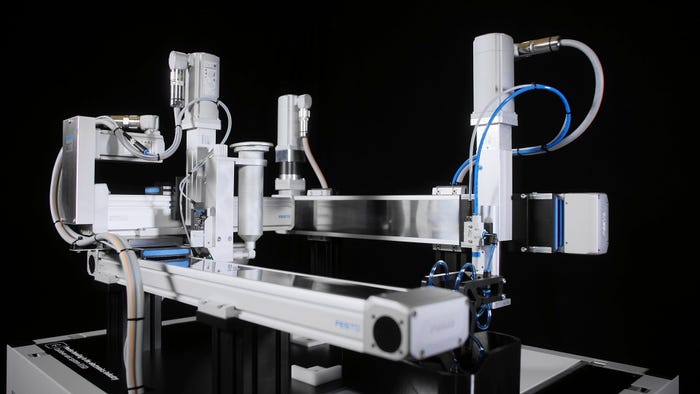

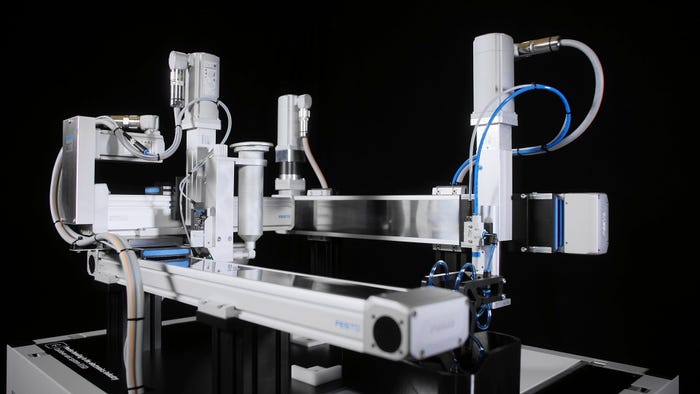

Motors, Actuators, Conveyors

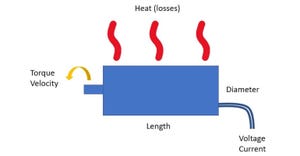

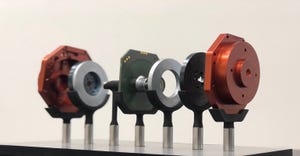

new generation of actuators

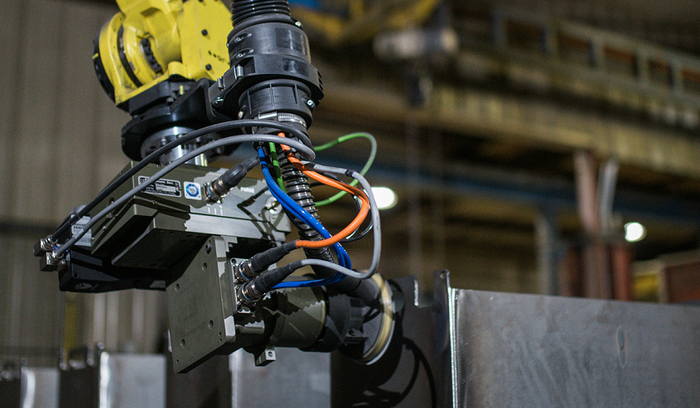

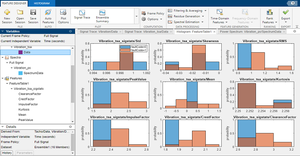

Automation

Festo Introduces New Generation of Electric Actuators for Linear ApplicationsFesto Introduces New Generation of Electric Actuators for Linear Applications

Festo’s new actuators are designed to improve axis performance while enabling high loads in a compact footprint.

Sign up for the Design News Daily newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)