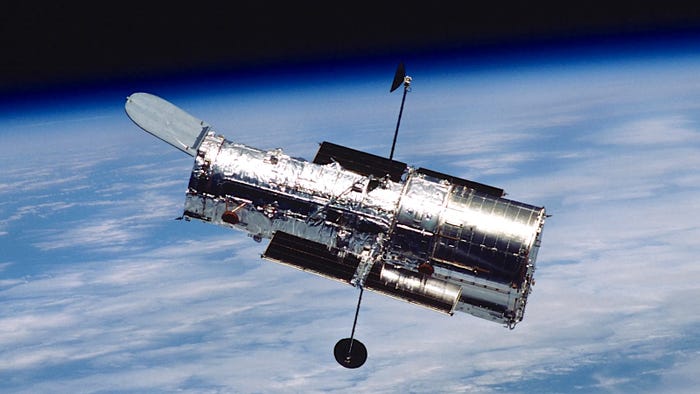

The Hubble space telescope in orbit.

Industry

Video: NASA Goddard's 40 Years of Non-Stop Hubble OperationsVideo: NASA Goddard's 40 Years of Non-Stop Hubble Operations

NASA's Goddard Spaceflight Center opened its control center 40 years ago.

Sign up for the Design News Daily newsletter.