Growth in Model-Based Design for Automation Control

September 18, 2013

If we look back five years at the number of automation system suppliers that could import a control algorithm into their automation software tools from a simulation environment, there were very few companies on the list. Not many automation systems were building targets for importing from a simulation environment into their automation control platform through code generation.

But now, according to industry experts at The MathWorks, the list has grown much longer. Systems are adding new sophisticated functions and tools.

"Siemens has a new target for their PC platform, and Omron just created a target for their PLCs that works with Simulink, The MathWorks' PLC coder product," Tony Lennon, The MathWorks industry manager for North America, told Design News. "The build-up over time is significant and it is a trend where machine builders know [it] is important to move to system simulations earlier in the design process."

Typically, machine builders have been experts at mechanical design and sizing motors for a given static load, for example. But system integration gets more difficult for the OEM when adding software sophistication to machines for controlling more complex systems with multiple axes and for coordinating large numbers of motors.

"What I can confirm is that in the mechatronic development process, software is growing in importance and is the main part of OEM machines," said Phillip Wallner, The MathWorks' industry manager for the company's European Region. "Machine builders usually have sophisticated processes for developing mechanics but often lack in good processes for developing software solutions. Software is written during the commissioning of the machine and, as it grows more complex, it becomes a larger challenge. As a result, simulation and more sophisticated software approaches are of growing importance for machine builders."

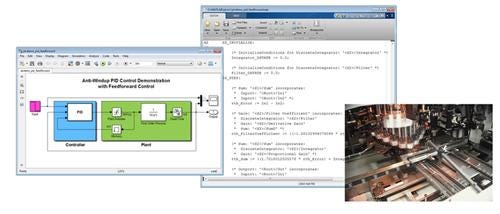

Lennon said that the aerospace and automotive industries use simulation tools because they realize people can't always be testing physical prototypes. But now the level of complexity and amount of code going into modern machines is causing machine builders to recognize the value of simulation, as well. Automation vendors are helping to build this bridge between the simulation environments and automation-control products. The code in a system-level simulation can now be easily ported into the actual production software that is used to drive machines.

"With the challenges going forward, from the CAD point of view, we have a very accurate animation of machines and seeing the 3D motion of the parts, which captures the dynamics of the machine", said Lennon. "But that environment is not good for developing controls because it is based on developing 3D shapes. Simulations need to look exactly like […] controls [an] engineer would draw up[,] a control diagram, with blocks and lines to describe the inputs and outputs, feedback signals, and so on to control the machine."

He said machine builders want to see a marriage of those two environments, which poses a challenge because they do work on some different underlying software principles. The MathWorks has worked with CAD vendors to import the mechanical information en masse, the hard geometry, the ways joints are connected together, and the inertias that define the dynamics of the system.

About the Author(s)

You May Also Like