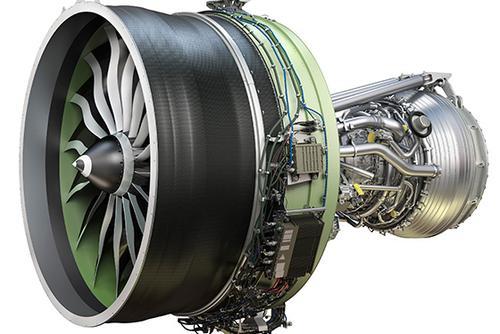

GE Redesigns Carbon Composite Blades for GE9X Engine

September 11, 2014

Carbon fiber composites aren't a new thing in jet engine fan blades, including GE Aviation's. But every so often GE engineers have to redesign them to take advantage of advances in carbon composite technology. This year, the company is designing new blades for the upcoming GE9X engine that will be thinner, lighter, and at least as strong as the composite blades on its existing engines.

GE Aviation says the new blades will be redesigned using a carbon composite with a new epoxy resin and a stiffer carbon fiber. To enhance the blade's strength, the leading-edge material will be changed, from titanium to a steel alloy. The GE9X engine's overall performance and fuel burn will be aided by the thinner blades, as well as by the smaller number of blades -- 16 -- planned for the engine. The combination will improve the engine's airflow and make the fan lighter and more efficient.

The new carbon composite fan blades will debut in the GE9X, according to a GE Reports article. They represent the first redesign in a decade. They are part of the fourth generation of such blades and will also have improved aerodynamics. Existing GE engines that incorporate carbon composite fan blades are the company's GE90-94B, GE90-115B, and GEnx engines. You can find out more about the manufacture and testing of GE's carbon composite fan blades for the GEnx and GE90 engines in this video.

Material testing on full-sized GEnx blades last year was successful, and the material continues under test. Next year, GE will begin testing the new blade design for the GE9X. During 2014, GE will spend $300 million on the testing and development of new technology for the new GE9X engine, which also includes ceramic matrix composites and 3D printing. Fan blade testing will include Universal Propulsion Simulator (UPS) fan performance tests.

The GE9X widebody engine is a 100,000 lb thrust class engine. It's destined for the Boeing 777X twin-aisle aircraft, which will enter service in 2020. It will be the most fuel-efficient engine GE has produced, with 10% better aircraft fuel burn compared to the 777-300ER powered by the GE90-115B. The first full core test is scheduled to occur in 2015, while the first engine test will be in 2016. Flight testing on GE's flying testbed is expected in 2017, and engine certification in 2018.

Related posts:

About the Author(s)

You May Also Like