Added Value Electronics Turn Normal Batteries Into Smart Battery Packs

November 13, 2013

Batteries have come a long way since their invention, from Volta's voltic pile of zinc and copper plates to today's high-tech lithium-ion batteries. The energy density (both volumetric and gravimetric) of battery cells has steadily increased over the years with new battery chemistry.

However, these increases and the use of volatile materials have made cells less stable and have required added electronic safeties. Modern battery cells have electronic safety circuits added to ensure that design parameters are never exceeded. Lithium rechargeable batteries require electronics safety circuits as a minimum. Cell balancing helps keep multiple series cells' primary safety circuits from activating incorrectly in addition to keeping them in line to improve run-time and cycle life. In addition, batteries used in medical and IT applications are required to have secondary safety circuits present in case the primary circuits fail.

The following added value technologies are part of the reason today's batteries can be viewed more as power systems/power supplies than as simple batteries.

Embedded battery chargers

With embedded battery chargers, unregulated power can be used to charge the internal battery from a number of sources: inexpensive wall bricks, car cigarette adaptors, USB ports, and wireless charging pads.

Advantages of embedded charges:

Increased battery life: The cells are always properly charged under all environmental conditions

Unauthorized battery chargers are unlikely to damage the battery

No need for external chargers

Perceived simpler solution by the end user

Disadvantages of embedded charges:

Increased initial cost, which may be negated with increased battery life

Functioning charger circuitry is discarded at the end of battery life

Wireless battery chargers

In the past, wireless battery charging relied on each company's proprietary design. The Inductive Power Standard (QI) lets companies like Epec embed wireless charging electronics into batteries to work with off-the-shelf wireless charging pads that already exist. Custom charging pads can be designed to match a product cosmetically, though there may be limitations in power depending on the application.

System output power

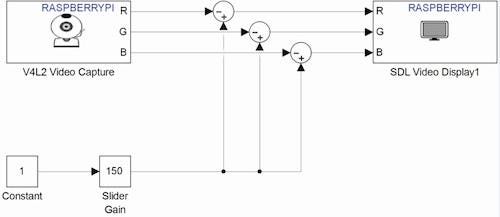

As part of an embedded battery charging solution, a battery can be powered as it is being charged. Input power can be very limited using a small wall brick, a wireless charger, or a USB charger. In these cases, reducing the charge current to the battery when the system is momentarily demanding more power is required so that the input power is not overloaded. This is done by having two current loops, as shown in figure 1. The red loop defines the total current that can be used by the system and battery pack while the blue loop defines the maximum battery charge current. As the maximum total current defined by the red loop is reached, the charge current to the battery is reduced proportionally to zero if needed. However, care must be taken not to draw more power than is defined in the red loop, since this could still overload the input power supply.

About the Author(s)

You May Also Like