Researchers Use DVD Burner to Fabricate Microcapacitors

April 24, 2013

UCLA researchers have designed a new way to fabricate microcapacitors that could provide a more efficient and cost-effective way to provide energy sources for micro devices that charge 100 to 1,000 times faster than standard batteries.

Richard Kaner, a member of the California NanoSystems Institute at UCLA and a professor of chemistry and biochemistry, and Maher El-Kady, a graduate student in his lab, have come up with a way to use a DVD burner to fabricate micro-scale graphene-based supercapacitors that can be used in medical devices like next-generation pacemakers.

The microcapacitors also are flexible, which means they could have applications for wearable medical technology like sensor patches, as well as other small devices that can bend and fold.

The pair's micro supercapacitor work stems from the invention of a graphene-based macro supercapacitor that Kaner believes could revolutionize the use of batteries for a range of devices -- including everything from mobile phone and electric vehicles -- because it can charge in an unbelievably short time. "Think of having your cell phone charge in less than a minute. This has really resonated with people. You would never have to worry about your electronic devices (being without battery power). That's the promise," he told Design News.

Kaner and El-Kady's macro supercapacitor work, which they have been doing simultaneously with their micro supercapacitor research, was featured in a short film they submitted to the Sundance Film Festival as part of a competition to demonstrate a technology that could change the world. That film has since gone viral on the Internet, Kaner told us.

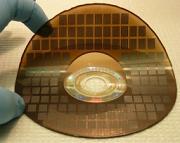

While the microcapacitors fabricated via DVD burner wouldn't have enough energy to power a mobile phone or an electric car, the ease of manufacturing them and potential use for a broad range of low-power devices makes them a good option especially for small medical devices. "You're not going to get super high energy, but if you're looking for (power for) health monitors or flexible, tiny devices... the idea that you could make 100 (microcapacitors) on a single CD in a short period of time using an inexpensive technique (is attractive)," Kaner said.

Currently, manufacturing these microcapacitors involves labor-intensive lithographic techniques that make the commercial application of them cost-prohibitive. The micro-supercapacitors developed by Kaner and El-Kady also can be integrated directly on chip, giving them potential to harvest energy from solar, mechanical, and thermal sources and thus be self-sustaining. Additionally, they could be fabricated on the back of solar cells in both devices and rooftop installations to store power generated during the day for later use.

Kaner said they are currently working with a leading supercapacitor company to see if the macrocapacitors can be put to use while considering how to apply the microcapacitors commercially.

There is currently a flurry of research activity in the design of new types of batteries and other energy sources, as well as in energy harvesting, to devise more efficient and cost-effective ways to power a range of devices. Researchers from a number of leading institutions -- including MIT and USC -- also are tackling this problem.

Related posts:

About the Author(s)

You May Also Like