In this opinion piece, Titoma argues the pros and cons of electronic design and manufacture outside of China.

October 5, 2021

Keesjan (Case) Engelen

Manufacturing electronics in China has its downsides. Among these is the theft of intellectual property (IP), as demonstrated by Cisco’s ongoing lawsuit with China-based Huawei.

Regardless, people have been manufacturing in China for a while because they have the world's most powerful electronics manufacturing ecosystem. Further, China has developed the expertise and infrastructure to manufacture almost any electronic device.

Even with the tariffs imposed on Chinese electronics by the previous Trump administration, many companies stayed because the costs of moving out of China for electronics manufacturing still outweigh the taxes.

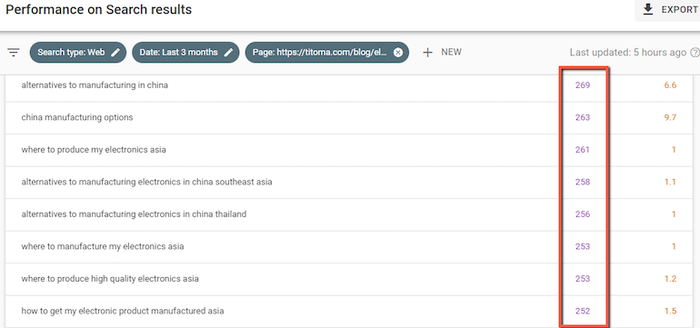

The struggle is real. In the past year, we've seen queries such as the one shown in the image.

Are we in a world where manufacturing quality electronics at affordable costs outside China is impossible? Of course, not. Two places come out as good options for complex electronics design and manufacturing: Taiwan and Malaysia.

Taiwan

Taiwan was the big electronics manufacturing player before everyone moved to China, and they're still in control of manufacturing behind the scenes.

Taiwan headquarters 6 out of the top 10 electronics manufacturers in the world.

Companies like Apple might manufacture their products in China, but they do it under the supervision of Taiwanese companies. Further, the geographic location of Taiwan is perfect, right next to China, giving it access to the vast electronics ecosystem the Chinese mainland offers. Finally, Taiwan has developed the skilled labor force needed to manufacture the most advanced chips in the world.

When you're in the early electronic design stages, particularly complex ones, you need to test different PCB shapes, components, and parts until you reach the minimum viable products. Language is another factor worth mentioning. Having smooth and clear communication channels is vital for success.

Being close to China could mean a smoother manufacturing process, as you'll still need Chinese components to bring your product to life. If your manufacturing operation is across the globe, you might set yourself up with a logistic nightmare.

The following characteristics make a country a realistic alternative to China manufacturing for complex electronics:

Electronics manufacturing expertise

Highly skilled workforce

Proximity to China for sourcing components fast

Ease of communication

Such characteristics bring us to our second option, Malaysia.

Malaysia

Malaysia isn't the southeast Asian country you were expecting to hear. When moving operations south of China, Vietnam is probably the country that comes to mind. Unfortunately, Vietnam only works for assembly, not design and manufacturing.

Malaysia's electronics industry is a crucial contributor to its economy and one of its key export destinations in the USA. Malaysia is next to Singapore, which gives it access to experienced engineers that can communicate in both Chinese and English. Malaysia is still within proximity to China, giving it fast access to its electronics components ecosystem. Another plus is that labor costs and export taxes in Malaysia are lower than in some areas in China, such as Qingdao.

But are Taiwan and Malaysia the only options for chip design and manufacturing? The answer depends on the electronic device you're looking to manufacture. If your device is of low complexity, you can ship components and parts kits to any country in the world and have them assembled there. All you need is a good purchasing and sourcing team and a capable labor force.

But if you're working on new and complex electronics, being close to China means access to a large pool of components for all the iterations your electronic will go through.

When it comes to more developed countries in the Asian sphere like Japan and South Korea with the expertise and technology for electronics manufacturing, labor costs are the primary barrier.

Keesjan (Case) Engelen has 20 years of experience designing and manufacturing electronics in China and Taiwan and is the founder of Titoma, an electronics design and manufacturing company.

Gain the latest insights from industry experts! Join DesignCon Digital for 2 days of education, sourcing, and networking, Oct 5 and 6, 2021. Register here.

You May Also Like