Airbus European Service Module is Ready to Fly

The first non-US-supplied major component to a space system sits atop the Artemis SLS rocket.

An artist's conception of the Orion capsule and service module orbiting the Moon.Image courtesy of Airbus

While the Artemis Space Launch System (SLS) rocket employs many repurposed Space Shuttle components for its booster, there’s no shuttle as the booster’s payload. Instead, Artemis carries the Orion capsule for its astronauts, and that capsule is ferried by a service module provided by new NASA supplier Airbus.

“It is the first time for NASA to trust a non-us company to make such a significant contribution to a mission,” noted Ralf Zimmermann, head of moon programs for Airbus. The company has a 60-year history building spacecraft, he points out, so while Airbus may be new as a NASA provider, the company has a long history in the industry.

For example, Airbus built the Columbus External Payload Facility for the International Space Station, and the company delivered five Automated Transfer Vehicles, which were uncrewed ferries that delivered supplies to astronauts aboard the ISS.

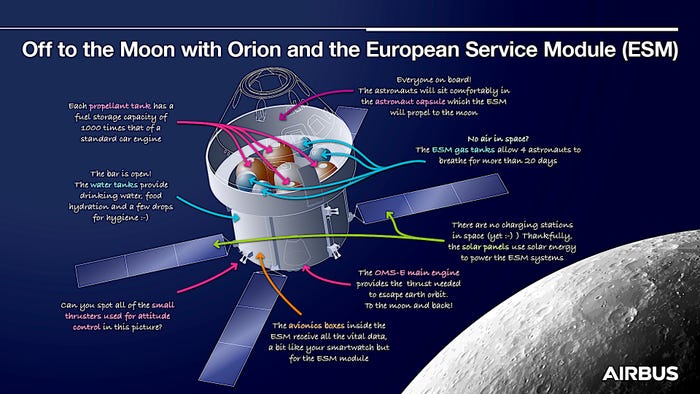

For the Artemis 1 test mission, there are no astronauts in the Orion spacecraft. Instead, it carries instrumented dummies to confirm the vehicle’s ability to safely carry people to the moon and back during this flight. Once the SLS booster has gotten Orion to orbit, the rest of the mission depends on Orion’s Airbus-built European Service Module (ESM), which provides a main engine for the trip to and from the moon, thrusters for positioning the capsule, solar panels for electric power, and life support systems for future astronauts.

The ESM is similar to the Apollo-era service module, which gained notice when an oxygen tank in Apollo 13’s service module infamously exploded during flight and precipitating commander Jim Lovell’s understated call that, “Houston, we’ve had a problem.”

The modern Orion European Service Module will hopefully avoid any such drama on any of its planned flights. The next flight will carry a crew to lunar orbit and the third is scheduled to land astronauts on the moon.

The ESM, which measures about 13 feet in length by 13 feet in diameter, weighs more than 13 tons, most of which is its 8.6 tons of propellant for the main engine, eight auxiliary engines and 24 smaller navigation and attitude control thrusters.

In flight, the ESM looks distinctly different from the Apollo service module because it deploys an array of four solar panels, providing the Orion with much more electrical power than was available from the Apollo module’s batteries. This also marks the main technical difference between the old and new systems, observed Zimmermann.

Those panels stretch 62 feet tip-to-tip, providing 11 kilowatts of inexhaustible power for the spacecraft. The crew’s flight duration is limited by the supplies of water and oxygen, which are sufficient to provide the crew of four for 21 days. A two-person crew could go twice as long, though living in the Orion capsule for 42 days might be an unwelcome experience, Zimmermann acknowledges.

The ESM consists of more than 20,000 parts and components, from electrical equipment to thrusters, solar arrays, propellant tanks, life support materials and miles of cables and hoses. Airbus has six modules built or in the works, as the structure for the fifth ESM arrives at the company’s Bremen, Germany plant for integration by the end of this year and the sixth one will be there by next summer.

Airbus has already delivered the first two to NASA, with #1 on the Artemis uncrewed test flight and #2 in preparation for its crewed launch next year. Module #3 is still in Bremen in an advanced stage of completion, so it will soon ship to NASA in preparation for its role in the planned lunar landing flight.

|

The ESA’s core is derived from the uncrewed ATM that delivered supplies to the ISS, but with necessary upgrades. In addition to its main engine, the ESM needed to have many of its systems backed up with redundant components to protect the crews.

“It was not easy at the beginning of the development,” Zimmermann recalled. “It took quite some time to deliver module number 1 and number 02,” he said. Despite the company’s experience building the ATM, the differences were enough to make creating the first ESM a tough job. “It had a completely different mission, so there was a new spacecraft design with different loads. The propulsion is more complicated with a main engine. It has full redundancy over many valves. The high-pressure tank is 400 bars.”

All of those systems are sorted and ready for flight on the Artemis 1 mission, so Zimmerman says that the ESM will have a couple milestones to meet before he can relax. First, it has to fire its main engine successfully. Then, once underway, it needs to unfurl its solar panels. When that solar power comes on line, it buys the engineering team a lot of flexibility for addressing any issues that might arise. “If you don’t have power, you are in a high-stress situation,” Zimmermann said.

Hopefully the mission goes smoothly from start to finish, once it finally gets off the ground after various launch delays.

About the Author(s)

You May Also Like