Curious Engineers Need to Understand Field-Based PCBs and L2+ ADAS Systems

Engineers learned from PCB and ADAS experts during the DesignCon complimentary webinar series.

May 17, 2021

The DesignCon Spring Break virtual webinar series was anything but dull. Daniel Beeker, Senior Principal Engineer at NXP Semiconductor, shared a field-based perspective on high-speed PCB design. Finishing up the last day was Danny Kim, Director of Advisory Services at VSI Labs, who delivered an OEM update of trends in the “new” advanced driver-assistance systems (ADAS) for autonomous vehicles.

You can register for on-demand viewing of all of the sessions here. Now, let’s look at what’s been covered in the last few days of this technically rich webinar series.

Field-based High-Speed PCB Design

Beeker began his presentation by noting that good signal integrity and electromagnetic compatibility (EMC) start with a solid printed circuit board (PCB) design philosophy, which includes a clear understanding of the behavior of electromagnetic (EM) fields. Proper design of the invisible spaces these fields follow through the board is critical. Creating transmission lines that will meet the needs of the power distribution network (PDN) and the fast-switching ICs in today’s high-performance products can be a challenge.

Beeker presented an easy-to-understand science-based approach to PCB design covering the basic behavior of EM fields as they move through the board and ways to control them. Considering the characteristics of the ICs on the design of the PCB layout provides for a more balanced system. Other important topics were the characteristics to define the PDN component selection and placement, as well as knowing the interconnects needed to create the transmission lines that support these requirements. These characteristics can then be used to define the transmission lines that carry the high-speed signals.

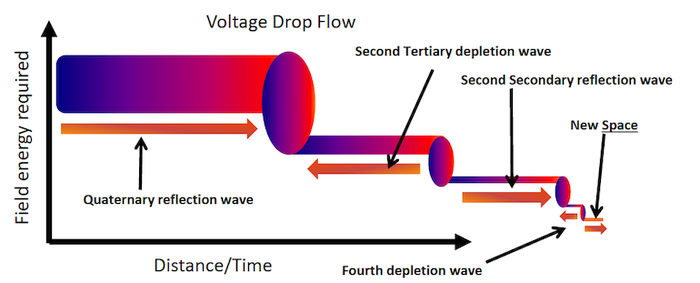

For example, proper power supply design results in depletion/reflection cycles with increasing cycle times and decreasing wavefront slope. Such designs are driven by the distance between field storage devices and their package sizes. Beeker emphasized proper power supply design would result in a virtual steady-state flow of field energy from the input power supply to the devices which then consume the field energy. The design goal was to manage the movement of field energy through the PCB board and component spaces.

OEM Roundup 2021: The New ADAS

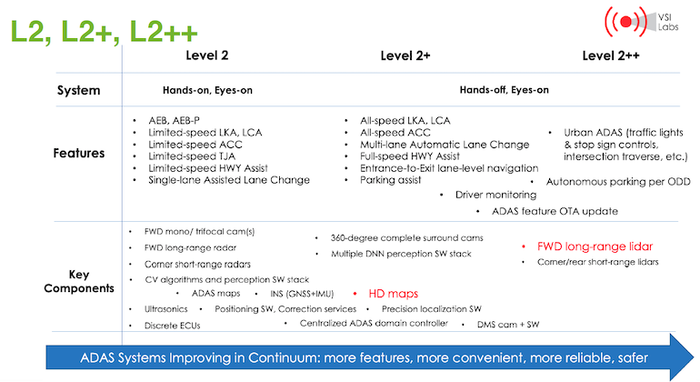

In its OEM Roundup, VSI Labs reported that automotive OEMs have debuted new and enhanced L2+ ADAS systems based on improved software algorithms, additional sensors, and more scalable platforms. A few OEMs have been interested in demonstrating L3 reliability in their new systems, while most others were busy enhancing features of their L2+ systems. While six levels of driving automation reveal that the biggest gap is between Level 2 and 3, OEMs are pushing to market L2+ and L2++ systems, namely “The New ADAS.”

What is L2+? It’s a term introduced by Mobileye at the 2018 Consumer Electronics Show (CES). When Mobileye promoted the Road Experience Management (REM) solutions along with L2+, they highlighted the high-definition (HD) map as being the single most contributing component to improve L2 systems. Then, At CES 2019, Nvidia joined in discussion with other key contributing enablers of enhanced ADAS: surround perception and AI, DMS, and AI cockpit technologies.

In his webinar, Kim investigated the latest trends and systems in OEMs’ consumer ADAS in 2021. One trend was that the industry had extended the definition of L2+ to embrace a certain configuration of ADAS systems that contained additional components. He shared what OEMs saw as the biggest gap of driving automation and how ADAS would fill it while covering the timeline expectations for L2+/L2++ in the ADAS technology rollout.

In addition to these free webinar sessions, registered attendees had the opportunity to enjoy a networking session at the close of the week, where they met with fellow attendees, set up one-on-one meetings, and got to know industry peers.

Further, registered attendees of the Spring Break Webinar can also look forward to receiving a discount code to attend DesignCon’s annual in-person conference set to take place between August 16-18, 2021, at the San Jose McEnery Convention Center, CA.

John Blyler is a Design News senior editor, covering the electronics and advanced manufacturing spaces. With a BS in Engineering Physics and an MS in Electrical Engineering, he has years of hardware-software-network systems experience as an editor and engineer within the advanced manufacturing, IoT and semiconductor industries. John has co-authored books related to system engineering and electronics for IEEE, Wiley, and Elsevier.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)