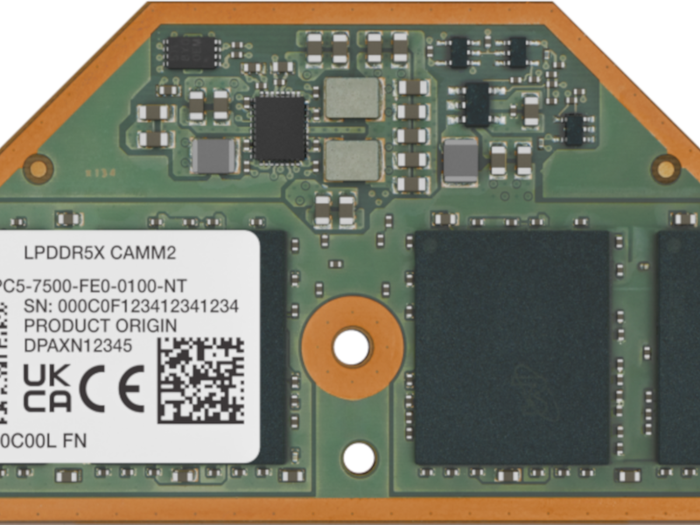

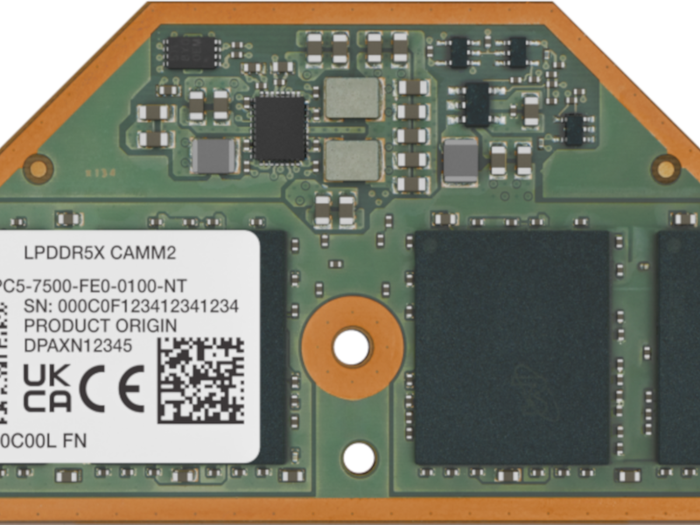

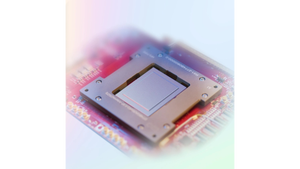

Micron's Crucial LPCAMM2 provides upgradeable mobile memory for AI PC applications.

Embedded Systems

This Laptop Memory Is Easily UpgradeableThis Laptop Memory Is Easily Upgradeable

New memory form factor promises power- and space-saving solution for mobile AI apps.

Sign up for the Design News Daily newsletter.

.jpg?width=300&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)