Building a Better On-Board EV Charger with Gallium Nitride

Texas Instruments’ gallium nitride semiconductor technology points the way toward greater efficiency.

Battery charging times remain an obstacle to customer acceptance of electric vehicles. But there are technical solutions that promise to whittle away at this time. gallium nitride semiconductors in place of silicon in EVs’ on-board chargers is one such technology, so we’ve called on Texas Instruments’ high-voltage power product line manager Steve Tom to describe its potential benefits.

Steve Tom manages the gallium nitride (GaN) product line within Texas Instruments’ (TI) High Voltage Power business unit, where he is responsible for overseeing and driving TI’s acceleration into the market through innovative product development and system-level advancements. He joined TI after graduating from the University of Michigan with BSEE and MS IOE degrees.

Design News: What are the areas for potential improvement in today’s EV power electronics and on-board chargers?

Steve Tom: When it comes to EV power electronics and onboard chargers, key consumer ‘care-abouts’ include charge time, driving range, and cost. GaN, and specifically TI’s integrated GaN FET and driver, are able to improve power density and efficiency allowing higher onboard charging power levels at smaller overall solution volumes. TI GaN maximizes switching frequency that minimizes power magnetics, which reduces the weight of the onboard charger and helps improve driving range.

DN: What is GaN when used as a semiconductor?

Steve Tom: GaN (or Gallium Nitride) is a new semiconductor material that (compared to traditional silicon) is a more efficient and faster switching material. These properties enable GaN to be used in AC/DC power supplies to increase efficiency and power density while reducing overall power loss. TI GaN uses internally manufactured GaN-on-silicon substrates for lowest cost and highest availability to enable supply chain capacity.

DN: What are its advantages over current technology?

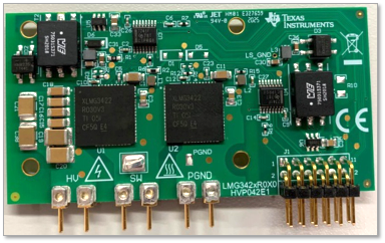

Steve Tom: GaN has superior device properties compared to existing technologies. In particular, lower input and output capacitance and zero reverse recovery enable GaN to be used in AC/DC power supplies that switch an order of magnitude faster than previous technology. TI GaN with an integrated driver furthers these benefits by optimizing switching times and leveraging an innovative low-inductance QFN package to minimize power loss and maximize switching slew rates.

DN: Why hasn’t it been used widely until now?

Steve Tom: TI GaN has been in development for almost ten years with first products being introduced as early as 2016. Since then, TI has released its full family of first-generation products targeting industrial, enterprise, and communications end equipment. The recent announcement of a 650-V, automotive GaN FET with integrated driver and protection extends TI’s portfolio into automotive and higher multi-kW applications for datacenter, 5G, and automotive onboard charging.

DN: What are its other potential applications?

Steve Tom: TI GaN targets a broad range of industrial and automotive end equipment where quality and reliability are important, including datacenter and enterprise AC/DC power supply units, automotive onboard chargers, communication 5G base stations, test & measurement equipment, industrial drive and high-density consumer AC/DC wall chargers.

DN: As a young technology, what is the potential for continued improvement of GaN technology?

Steve Tom: GaN will continue to improve both in switching performance to improve efficiency and power density as well as overall cost. TI’s focus on internal manufacturing enables a roadmap for high quality and reliability as well as the manufacturing scale for high volume and cost reduction.

About the Author(s)

You May Also Like