Building a Better Turbocharger

We look at how turbocharger technology keeps improving to boost vehicles' power, efficiency, and driveability.

Forced induction wrings the final efficiency gains available from internal combustion engines, so the automotive industry is moving toward universal use of turbochargers on gasoline engines, as already happened with diesels previously.

Turbochargers have historically suffered from some characteristics that turned drivers off, most especially the lag time it can take for a turbo to spin up to speed when the driver opens the throttle abruptly and catches the turbo at low boost pressure.

Turbocharger manufacturers are addressing that issue with a variety of techniques designed to deliver power, efficiency, and satisfactory driving experience.

Design News talked to BorgWarner’s director of engineering, Douglas Erber, to hear about the direction of turbocharger technology.

DN: Are combustion engines likely to all be turbocharged in the future, and if so, why?

Douglas Erber: Absolutely! Turbocharging is an essential technology to meet OEMs’ targets for fuel economy, emissions, transient performance, and peak power. All new combustion engines are being designed with very specific turbocharging needs in mind.

DN: What are the critical technologies exhibited in today’s state-of-the-art turbochargers?

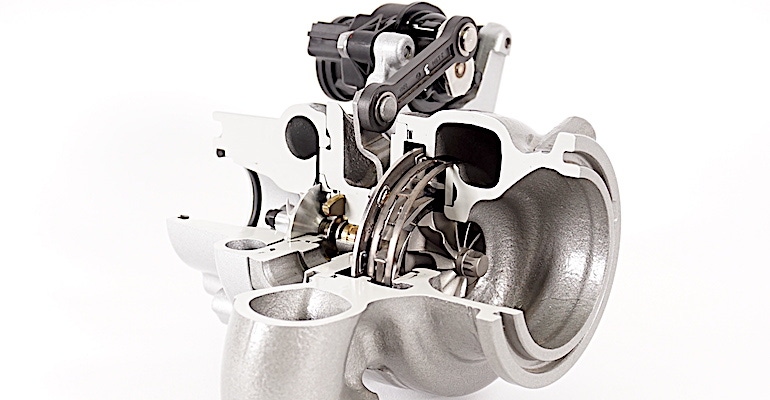

Douglas Erber: Variable Turbine Geometry (VTG) and Dual Volute Connect (DVC) will play an even bigger role in future light-duty segment vehicles as both technologies enhance the operating range of a turbocharger. Electric actuators (rotary or linear) will become the standard for controlling wastegates, variable geometry vanes and volute connect valves.

DN: What are the emerging technologies that we will see to make turbos even better?

Douglas Erber: Ball bearings will be used in both passenger and commercial vehicle applications due to reduced friction (improving efficiency) and superior transient characteristics.

The next step in the innovation will be the industrialization of eTurbos. An eTurbo is a turbocharger with an electric motor located between the compressor and turbine stages. Electricity can either be applied to or harvested from the eTurbo.

When electricity is applied, the eTurbo rotor group provides an instantaneous boost response. Or, under certain operating conditions, electricity can be harvested from the eTurbo and used to re-charge vehicle batteries.

DN: What role will things like variable turbine geometry, two-stage turbocharging, electric turbochargers, and dual volute turbos play?

Douglas Erber: Gasoline VTG and Dual Volute Connect will play a larger role over the next few years in the passenger vehicle market. eTurbos will first be used in high-performance niche markets before becoming more mainstream. Two-stage turbocharging has barriers in cost, weight, and complexity and will primarily be used in high-pressure ratio commercial vehicle applications.

DN: What are the most difficult challenges facing improved turbochargers, such as materials used, or cost, or whatever it might be?

Douglas Erber: At BorgWarner, the innovation never stops. Every single individual turbocharger component is continuously being optimized with CAE tools to find the most suitable design and material to meet performance, durability, and cost targets.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)