ESP32 SoC Eliminates Wires for Bluetooth Remote Control Applications

The ESP32 System-on-a-Chip enables wireless connectivity for machine-to-machine communication from PLCs to IoT sensors.

March 16, 2021

Industrial controls have evolved from the days of hardwired relay logic-based units to sophisticated internet-connected systems. Legacy-based machine controls’ intelligent processes were configured using basic computer logic circuits. These basic computer logic circuits were created by appropriately wiring the relay contacts to perform such low-level control actions. With the advent of digital controls-based on programmable logic controllers (PLC) and computerized ladder logic software, industrial controls can make complex decisions aided by electronic sensors. One improvement made by the digitization of monitoring and processing functions is the method of machines to communicate with each other. Also, with this machine to machine (M2M) communication method, reduction in wiring through cable bundles are achievable using such digital techniques. An Internet of Things (IoT) wireless approach that has aided M2M improvements in industrial controls is Bluetooth (BT) technology.

Bluetooth’s Benefits

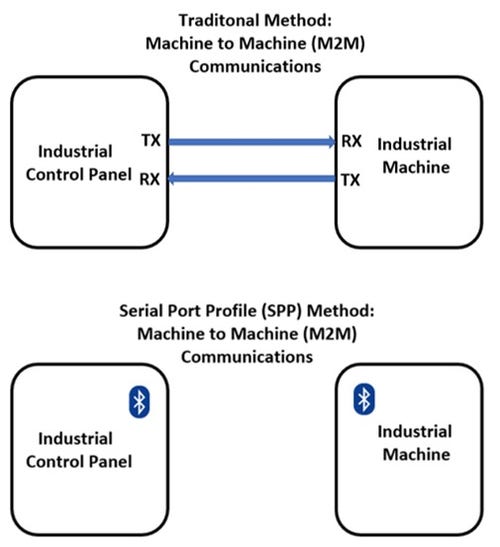

Wireless technologies allow the design of industrial control functions to be adaptable. One area of adaptability is the location of the operator control panel from the target industrial machine. BT’s primary benefit is the reduction of cable wiring between the operator control panel and the intended industrial machine. With a specific BT profile selected, the operator control panel can easily and effectively communicate with the industrial machine’s actuators. Establishing an M2M communication network allows the exchange of control command data over a short-range wireless network. Instead of having a serial cable stretched between the operator control panel and the industrial machine, M2M communication can be achieved using BT technology.

Serial Port Profile

Although there are a variety of BT profiles to select from, the most appropriate one is the Serial Port Profile (SPP). SPP is a profile that replaces the traditional hardwired serial communication interfaces. The most common serial communication interfaces deployed in traditional industrial M2M systems include RS232, RS485, Profibus, or Universal Asynchronous Receiver Transmitter (UART). The original use of BT back in 1998 was the replacement of hardwired communication cables with a cost-effective wireless solution. With BT SPP, industrial devices can easily, connect exchanging data in a receive-transmit communication method. Now, the BT SPP can be implemented using a low-cost IC device wireless point-to-point solution.

ESP32 System on a Chip

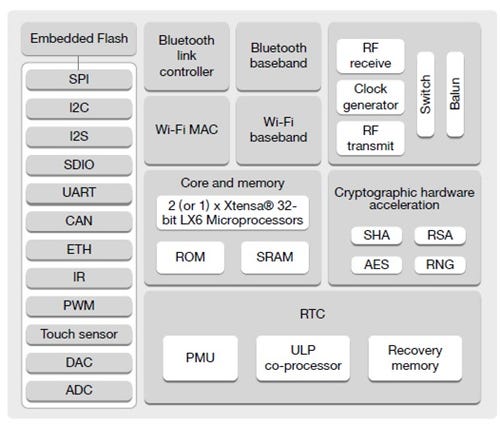

The implementation of a cost-effective wireless M2M industrial control method solution is with an ESP32 System on Chip (SoC) device. The ESP32 is a Complementary Metal Oxide Semiconductor (CMOS) Wi-Fi and BT IoT application single-chip device supported by integrated electronic circuits. These circuits consist of an antenna switch, RF balun, low noise receive amplifier, power amplifier, and power management modules. In addition to these support electronic circuits, the ESP has an Xtensa dual-core 32-bit microprocessor, 4Megabytes (MB) of Serial Peripheral Interface (SPI) Flash memory, 520Kilobytes (KB) Static Random-Access Memory(SRAM), and 448KB of Read-Only Memory (ROM). Also, the ESP32 supports Wi-Fi through a Media Access Controller (MAC) and baseband circuits. Moreover, the ESP32 can be operated by USB or from a lithium-based battery of 3.3V.

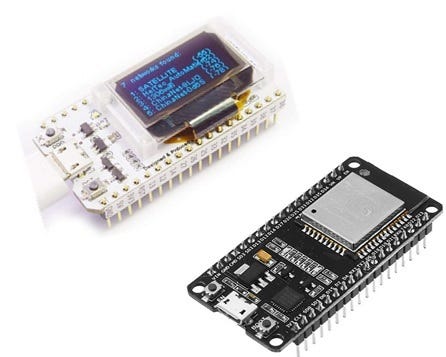

To allow ease in prototyping Industrial Control M2M solutions, development boards are available.

BT Controller Prototyping Example

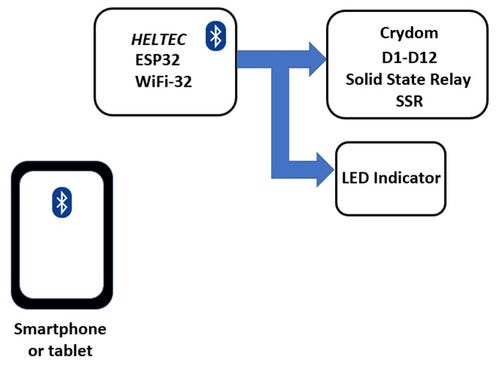

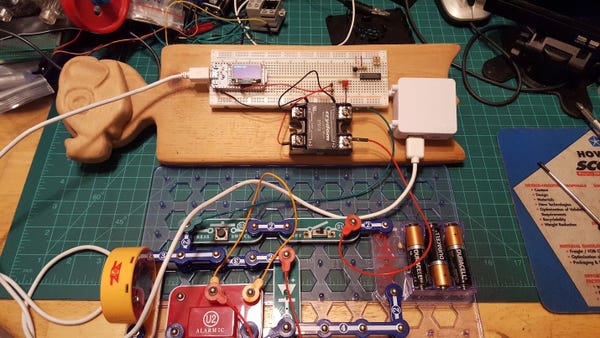

Development boards allow rapid prototyping concepts to be realized. To illustrate this concept, a simple ON/OFF controller is required to operate a small electronic oscillator. The electronic oscillator produces an audible effect of a space gun sound upon being switched on. The traditional approach of using a manual Single-Pole, Single-Throw (SPST) switch as a remote control to operate the electronic oscillator can be hardwired as a solution. A disadvantage of this solution is providing a sufficient length of wires to operate the electronic oscillator from a variety of locations. An effective remote-control solution is to deploy a BT SPP approach to achieve the operation of the electronic oscillator from various locations.

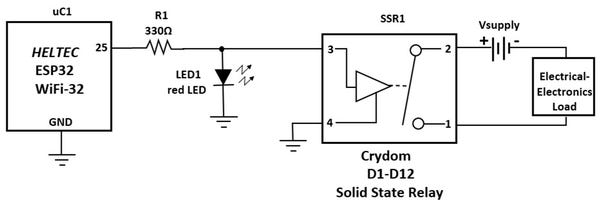

The smartphone or tablet will serve as the industrial Human Machine Interface (HMI) controller to switch ON and OFF the electronic oscillator. The electrical switching of the electronic oscillator is accomplished by a solid-state relay (SSR). The SSR will switch on an external power supply, thereby electrically operating the electronic oscillator. Also, the SSR is enabled by the ESP32 commanded by BT of a smartphone or tablet. Also, a red LED provides a visual status indicator of the SSR being enabled by the ESP32 SoC device. As illustrated, the electronic oscillator is represented by the electrical-electronics load circuit block. Besides an electronic oscillator, small dc motors, lamps, LED and LCD panels, or solenoids can be controlled by the SSR. Such devices can be used in small industrial control applications like conveyors, jogging, robots, or process monitoring devices. With the electronic circuit schematic diagram, an ESP 32 BT controller can easily be a prototype. Additional information on the HELTEC ESP 32 SoC device can be found on their website.

Don Wilcher is an electrical engineer, technical education researcher, instructor, maker, and author. He researches machine learning and artificial intelligence applications and their impact on personalized learning, competency-based-models curriculum, and instructional development in the fields of mechatronics, automation, electronics, and industrial maintenance technologies.

About the Author(s)

You May Also Like