Latest

Apple Unveils New iPad Amidst Jarring Video Promotion

Apple Unveils New iPad Amidst Jarring Video Promotion

Latest tablet stands on its own merits, but Apple's product promotion video raises eyebrows.

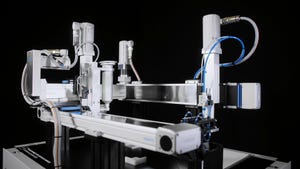

AMD, ECM, and GrayMatter Robotics nab innovation awards for breakthroughs in automation that push the boundaries of technology.

More News

This video by the Stewart-Haas team walks us through the process.

From Our Partners

Engineers and designers alike will find kindred spirits at the upcoming event to grow their networks.

Popular

Recent

Build a Better

Supplier News

See allBrowse dozens of products categories, see the latest featured products and white papers, and watch videos from top suppliers.

For displacement and distance measurements at ambient temperatures up to +800 °C, Micro-Epsilon now offers the robust, capacitive capaNCDT 6228 sensor system.

The RondelO is the world’s first medical stopcock manifold that provides a serial sequence of incompatible drugs and enables flushing fluid in between. These stopcock manifolds are available through Qosina in 2-, 4-, or 6-luer inlet ports with a through line for flushing fluid.

.jpg?width=300&auto=webp&quality=80&disable=upscale)