Fast-charging and nickel-rich chemistries will accelerate degradation of future EV batteries, expert says.

September 19, 2018

Many EV batteries may not last as long as consumers expect—especially if trends toward nickel-rich chemistries and fast-charging continue, an expert said at last week’s Battery Show.

Asad Farid of Berenberg Bank told engineers at the show that many of the newer breed of batteries will last, on average, only about five years. “We think the battery degradation rate in your electric car will increase rather than decrease going forward,” he said.

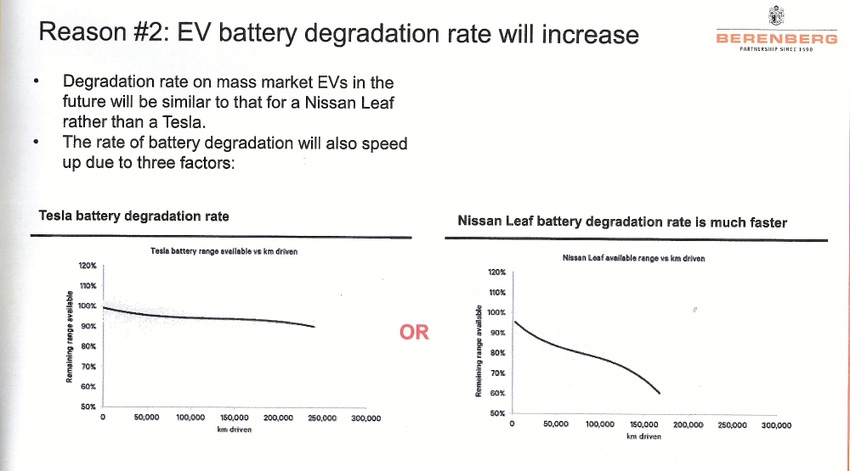

The shorter life expectancy will come as a surprise to those who believe all EV batteries will behave in a manner similar to that of Tesla Inc.’s big, actively cooled lithium-ion battery packs, Farid said. He predicted that many future batteries will exhibit the kind of “capacity fade” that Berenberg chronicled in early Nissan Leaf EVs. Those batteries exhibited more than 20% degradation after an average of five to six years of driving, he noted.

|

According to Asad Farid of Berenberg Bank, future EV batteries are likely to need replacement after just five years of use. “People believe their battery degradation will be similar to that of the Tesla,” he said (see graph on left). “But we think battery degradation will remain similar to the case of the Leaf going forward” (see graph on right). (Image source: Berenberg Bank) |

|

Asad Farid of Berenberg Bank: “We think the battery degradation rate in your electric car will increase rather than decrease going forward.” (Image source: Berenberg Bank) |

Farid cited three main reasons for the shorter life expectancy in future batteries.

First, he said, there’s a shift toward high-nickel cell chemistries in NMC (lithium nickel manganese cobalt oxide) and NCA (lithium nickel cobalt aluminum oxide) batteries. Those nickel-rich chemistries have shown a lower cycle life of 2,000 charges (for NMC) and 1,000 charges (for NCA). In contrast, the lithium iron phosphate batteries commonly used in China typically hit more than 3,000 cycles. In a paper published earlier this year, Farid contended that the move to high-nickel chemistries is caused by the growing desire for greater driving range. Unfortunately, the move to higher energy density (greater range) comes at the expense of longevity, he wrote.

Second, a shift toward faster charging speeds will reduce life expectancy, he said. Today, many utilities are installing DC fast-charge stations rated at 50 kW, 150 kW, and even 350 kW. And while such stations can charge big batteries in as little as 20 minutes, they also generate heat that can lead to decomposition of the battery’s anode and cathode. “When you triple the speed of charging, your battery degradation will also increase,” Farid said.

Third, the use of air-cooling leads to faster battery degradation, he said. Today, some OEMs are choosing to use passive air-cooled systems instead of more expensive liquid cooling, but such systems trap more heat in the cells. Farid said that the degradation rate with air cooling is more than double that of dynamic, liquid-cooled batteries.

In a session titled, “Lithium-Ion Batteries Most Critical Raw Materials: Lithium, Cobalt, Nickel & Graphite,” Farid told the audience that many other factors also contribute to shorter battery life. Among those are depth of discharge and size (capacity) of the battery. Because drivers are more likely to deeply discharge a smaller battery, smaller packs on average will not last as long as the bigger ones, he predicted.

To be sure, consumers who purchase EVs would be covered if the batteries degrade as rapidly as Farid predicts. Today, most manufacturers offer warranties—typically for eight years and 100,000 miles. Moreover, some states are providing protection for consumers who buy used EVs. California, for example, recently passed a bill that would provide a rebate to buyers of used EVs to replace the battery packs in their vehicles.

Moreover, the industry is aware of the heat problems associated with fast charging and is prepared to deal with it, other analysts say. “OEMs understand the desire for fast charging and are actively working to mitigate the impact through things like careful thermal management to keep pack temperatures down,” noted Sam Abuelsamid, senior analyst for Navigant Research, in an e-mail to Design News. “On the e-tron, Audi is making a big deal about the thermal management of the battery pack to support 150-kW charging, and Porsche is launching 350-kW charging on the Taycan in the spring.”

Either way, Farid believes that most consumers will want to replace their batteries sooner than eight years. Such purchases would be more cost-effective than replacing the entire vehicle, he said. “EV car owners will be tempted to replace their battery pack after four to five years, rather than buying a new electric car,” he said. “And if you buy an electric car from Nissan, BMW, or Renault, you can replace the battery pack for around $8,000.”

RELATED ARTICLES:

If owners choose not to replace the battery, Farid said, they could lose as much as 70% of the car’s resale value within five years. “The only thing wrong with your car (at that point) is your battery pack,” he said. “So if you can replace it, you can significantly increase the value of your car.”

Senior technical editor Chuck Murray has been writing about technology for 34 years. He joined Design News in 1987, and has covered electronics, automation, fluid power, and auto.

|

About the Author(s)

You May Also Like