New modular robots

Automation

ABB Expands Its Modular Large Robot PortfolioABB Expands Its Modular Large Robot Portfolio

ABB’s new IRB 7710 and IRB 7720 robots offer new levels of flexibility and greater choice with almost 50 variants.

Sign up for the Design News Daily newsletter.

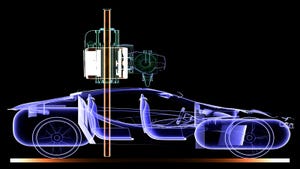

.jpg?width=700&auto=webp&quality=80&disable=upscale)

.png?width=300&auto=webp&quality=80&disable=upscale)

.jpg?width=300&auto=webp&quality=80&disable=upscale)