RobotExpert Brings Simplified Simulation to the Shop Floor

August 22, 2012

Shop floor robots, while not the most sexy or attention-grabbing, are definitely up there on the high-utility scale when it comes to robotics technology. Siemens PLM Software is attempting to make the programming of such shop floor robots easier with the latest addition to its manufacturing simulation software line.

RobotExpert, part of the company's Tecnomatix line of digital manufacturing software, is being positioned as an out-of-the-box solution for robotic simulation and programming, and is aimed at helping to maximize the speed, flexibility, and operation of automated systems. The use of robots is expanding rapidly in a variety of industries, and as a result, more tasks previously performed by shop floor workers are now been migrated over to robots for greater efficiency and to minimize repetitive human stress.

Traditionally, Siemens PLM Software officials said industrial robots have been programmed manually, which can lead to inefficiencies and non-optimized performance. Trying to create efficient manufacturing lines manually involves physical builds and trial by error programming -- a scenario that can end up being quite expensive and time consuming, officials said.

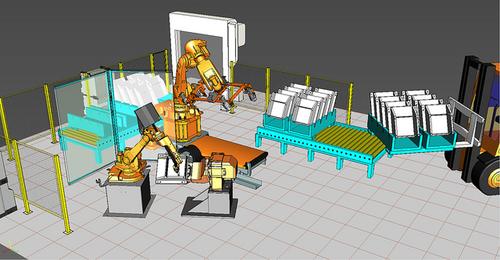

In order to create the optimal combination of manufacturing equipment in the shortest amount of time, it's far more efficient to employ simulation software. That's where RobertExpert comes in. It functions as an offline programming and simulation tool, allowing most of the programming work to be done virtually while at the same time, allowing for optimization that can help reduce cycle time and increase throughput.

Via what Siemens PLM Software officials say is an intuitive 3D user environment, production engineers can work in RobotExpert to optimize robotic paths and improve cycle times, using the software's simulation capabilities to test virtual mockups of complete manufacturing cells and systems. The software, which supports such common industry applications as pick-and-place, arc welding, polishing, and gluing, among others, can be deployed to generate the most suitable combination of equipment to achieve the manufacturing task at hand -- a capability officials claimed could help bolster product introduction cycles, as well as aid in the early evaluation of manufacturing times, costs, and project investments.

"Manufacturers, big and small, are under a great deal of pressure to maximize return on capital investment, and production line automation provides an excellent opportunity to help increase efficiency," said Zvi Feuer, senior vice president of manufacturing engineering software at Siemens PLM Software, in a press release.

RobotExpert supports 3D modeling of kinematics for tooling and includes support for an array of robots from vendors such as ABB, Fanuc, and Kuka. The software includes a comprehensive library of robots, but users can also create 3D models of additional robots or leverage the JT file format to import robot models from other popular 3D CAD tools.

Related posts:

About the Author(s)

You May Also Like