Mechatronics Solution Is Adept Enough to Produce a Bow-Tying Robot

December 10, 2015

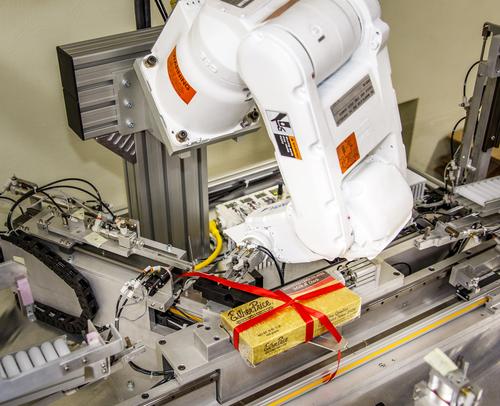

A robotic system has enabled Esther Price Fine Chocolates to automate the process of tying red-ribbon bows on its popular confectionery boxes. The company's tradition of finishing its packages with bows originated 60 years ago, when Esther Price personally filled chocolates into boxes and hand-tied a bow on each one, and until recently, attempts at automating the process proved difficult.

Automated ribbon tying

Workers at Esther Price Fine Chocolates could manually tie ribbons at a rate of three to four boxes per minute, sometimes achieving five boxes per minute, but no single person could tie boxes all day long. And workers risked carpal tunnel syndrome. The company initially considered several scenarios to automate the process. But there was no reasonable, cost-effective way of mimicking a worker's bow-tying movements without incorporating a robot.

According to mechatronics expert Dave Whelan, founding partner of aXatronics, the Cincinnati-based engineering company that developed the Yaskawa Motoman robotic system for the confectionery company, automating the bow-tying with a robot was something like teaching a six-year-old how to do it. "Replicating the bow-tying movement is very difficult," Whelan said. "It requires six axes of motion."

The main technical issues were repeatability and extremely slow throughput. Whelan said that as aXatronics investigated the process, the project became something of a "science experiment" because it was so hard to reliably handle a material as floppy as ribbon.

"The challenges for repeatability were centered on situations where the ribbon was hard to handle and the times during the process when the robot needs to let go of the ribbon," Whelan remarked.

He said that developing a repeatable method for the robot to release the ribbon and find it again was the biggest challenge, along with speed of operation. But the robot also needed to do its work in a compact work envelope located in the box-filling room. "To overcome the challenge of being able to locate the ribbon in the work space, the robot needed to be able to repeat certain motions precisely enough so that the hook that the ribbon is wrapped around can be effectively controlled," Whelan said. "The shape of the wire hook is extremely critical for the ribbon to be laid out in exactly the same position every time."

One factor that took a lot of time to resolve was the difference between a full spool of ribbon versus an almost empty spool, as ribbon acts very differently when it is near the end of the spool. This created a lot of trial and error to perfect the automated system operation and necessitated applying a lot of common sense to process.

"We could use a vision system to locate the ribbon, but that approach is more effective when there is a need to precisely locate a product at the start of the cycle. Once you have a grasp on the raw material in the process, the better solution is to keep it under control rather than needing to go find it," he added.

Mechatronics expertise a necessity

"The only successful way of designing a system like this is if the designer of the mechanical system also has a good appreciation of what all the other design disciplines can do and how the robot needs to be programmed to perform certain functions," Whelan said. Understanding of where to place sensors on the pneumatic cylinders and the response times that are achievable using the large Ethernet IP-connected digital I/O and pneumatic manifold in the system was critical.

A PLC controls all of the pneumatics and monitoring of all sensors for the 20 cylinders deployed in the robotic system. The overall process is a perfect example of mechatronics because the system depends on every engineering discipline, from mechanical design, to controls design, to software, to pneumatics. There is a lot of software and an operator interface driven by code that makes all of the disciplines come together.

About the Author(s)

You May Also Like