Researchers developed an environmentally friendly device suitable for single-use electronics like medical or environmental sensors.

November 9, 2022

Given the pollution crisis caused by the constant replacing of digital devices like smartphones with the latest and greatest releases, researchers have been seeking suitable recyclable or biodegradable materials from which to create electronic devices. To this end, a team from State University of New York (SUNY) at Binghamton have developed a circuit board made of a sheet paper that includes fully integrated electrical components but can be burned or left to degrade after use.

The invention evolves current paper-based electronic designs, which typically require specialized paper or merely have traditional metal circuitry components mounted onto a sheet of paper, researchers said. The approach not only can serve to create consumer devices that are more environmentally friendly but also can provide environmentally friendly disposability for the emerging field of single-use electronics, such as health or environmental sensors, they said.

"This work’s primary objective is to develop a cost-effective, eco-friendly, all-paper, device for single-use applications that can be easily and safely disposed of through incineration or biodegradation," researchers wrote in an abstract for a paper on the work published in the journal ACS Applied Materials & Interfaces.

Designing the Disposable Technology

Currently, most small electronic devices use circuit boards made from glass fibers, resins, and metal wiring, which are neither easy to recycle nor user-friendly for smaller devices like sensors or personal wearables.

The goal of the SUNY Binghamton team—led by Seokheun Choi, a professor in the SUNY Binghamton Department of Electrical and Computer Engineering—was specifically to develop circuitry that would be easy to manufacture and included all of the electronic components fully integrated into the paper sheet.

For their research, the team designed an amplifier-type circuit that incorporated a tunable resistor with a resistance of 20 ohm to 285 kiloohm, a supercapacitor with a capacitance of about 3.29 mF, and an electrolyte-gated field-effect transistor, using a fabrication process that involved a few steps.

The first entailed using use wax to print channels onto a sheet of paper in a simple pattern. They melted the wax so that it soaked into the paper and then printed semi-conductive and conductive inks, which soaked into the areas not blocked by wax. The final step was to screen-print additional conductive metal components and cast a gel-based electrolyte onto the sheet.

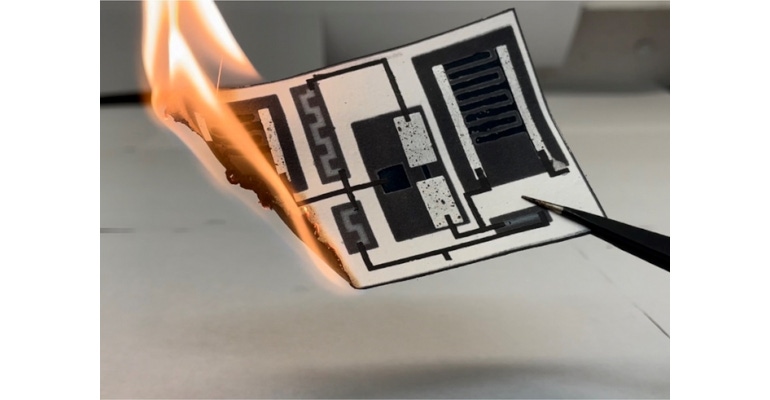

The resulting circuit was flexible and thin even with the addition of the electronic components; tests confirmed that the resistor, capacitor, and transistor designs performed properly. Researchers also demonstrated the degradability of the circuit by using fire to burn the entire unit to ash, they reported.

About the Author(s)

You May Also Like