Researchers in Japan combined two computational models to extract more data on certain types of metals from a single test.

November 23, 2022

Researchers are taking a new approach to creating databases that can be used to predict the properties and potential of new materials, a move that should streamline the process of choosing metal alloys for future research and development projects. Scientists from two Japanese institutions—University of Tsukuba and the National Institute for Materials Science in Japan—combined two computational models to extract more data on steel alloys from a single test.

Their method—which is focused on what are called "high work-hardening alloys" such as steel—uses data from one type of test on small metal alloy samples. This data is then used to extract enough information for building databases that can be used to predict the properties and potentials of new materials, researchers said.

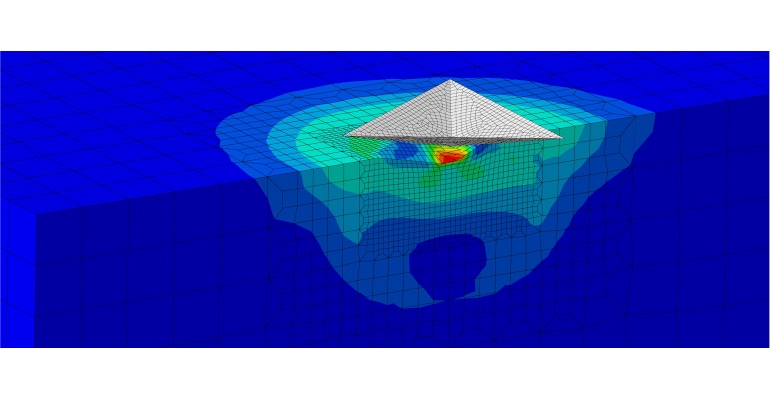

The test with which researchers worked is called instrumented indentation, which entails driving an indenter tip into a material to probe some of its properties, such as hardness and elastic stiffness. Historically, scientists have been using the data extracted from this test to estimate the stress-strain curve of materials using computational simulations, which provides data that's important to understand a material’s properties, researchers said.

Researchers also use the data to building massive materials databases, which then can be used—together with artificial intelligence—to predict new materials. This, in turn, helps scientists narrow down what types of materials to use in particular research, thus eliminating trial and error in the laboratory and saving time and money.

Stretching Limits

One area of limitation that researchers have faced with this test is in regard to discovering materials called high work-hardening alloys, such as steel, which are strengthened through physical processes like rolling and forging. Historically, researchers could only get so much information from the curve of these materials, with further experiments and tests required to glean more—costing time, effort, and, of course, finances, they said.

Researchers published a paper on their most recent research in the journal Science and Technology of Advanced Materials: Methods. Their report demonstrates how by combining results from two computational models—the power-law and linear hardening models—researchers can provide extra data to show a more holistic picture of the properties of one of these alloys, they said.

Specifically, each of the models produces its own individual stress-plastic strain curves from information gathered from indentation tests. When this data is added to the original stress-strain curve data, it widens the view of the material, researchers said.

"Our approach builds on an already-existing model, making it ready for use in industry," said Ikumu Watanabe, a researcher at the National Institute for Materials Science in Japan who worked on the project, in a press release. "It is also applicable to existing data, including hardness."

Researchers conducted experiments to validate the material properties determined by their enhanced modeling and found that generally they corroborated the predicated properties and potential, they said.

About the Author(s)

You May Also Like