Compact wave springs work in places where other types of springs will not, so they provide a great option in space-constrained applications.

We asked Smalley marketing engineer Justyna Rapacz to fill us in on the design of wave springs and their utility to engineers designing products. We turned to Smalley as the inventor of the edge wound wave spring to provide us an authoritative explanation of the benefits of this type of spring.

Design News: What is a wave spring?

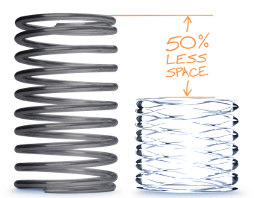

Justyna Rapacz: A wave spring is a type of compression spring made of flat wire with a unique 'multiple waves per turn' design. This innovative design is why a wave spring can offer the same spring force as a traditional round wire coil spring but at 50 percent of its operating height.

DN: What are the primary applications for wave springs?

Justyna Rapacz: From small to large diameters, light- to heavy-duty loads, carbon steel to exotic materials, wave springs have been the trusted, space-saving solution for tens of thousands of applications. From everyday consumer products such as the smartwatch on your wrist to life-saving medical devices such as robotic surgical instruments to extreme environments like oil wells deep under the Earth's surface, to as high as Mars, there is virtually no limit for wave springs.

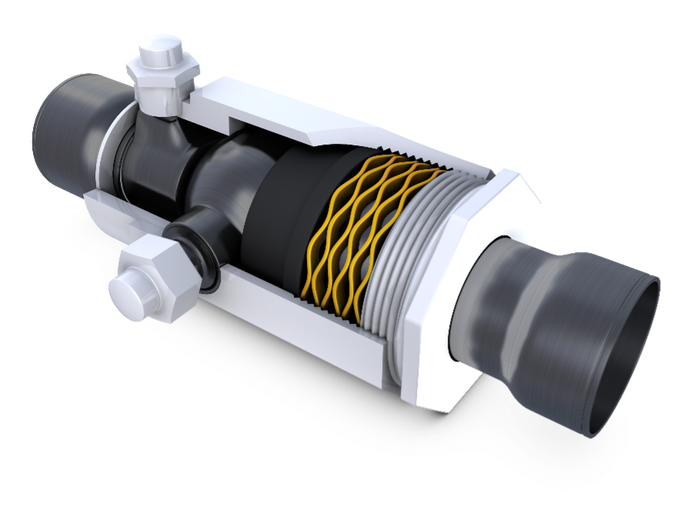

One common application that utilizes the benefits of a wave spring is a flow valve. While many spring systems can be designed into valves, engineers often choose wave springs because of their space-saving capability and linear compression behavior through 80 percent of the compression range. These unique features allow for more precise and repeatable control of both flow and pressure.

As fluid pressure increases, a Crest-to-Crest Wave Spring precisely controls the linear displacement of the piston.

DN: What are the benefits of using wave springs?

Justyna Rapacz: Whether you have space constraints, need more design flexibility, or are looking to meet a specific load requirement, adding a wave spring to your design tool kit can open up a world of new design possibilities. Wave springs optimize space in your assembly by providing the same spring force as an ordinary compression spring, but at a reduced operating height.

The top advantages of wave springs include:

|

Reduce spring height by up to 50 percent when used to replace an ordinary coil spring

Compact design fits tight radial and axial spaces, reduce spring cavity size

Light-weight assembly, save production time and material cost

Accurate and predictable load(s) toleranced at specific working height(s)

DN: What are the trade-offs if any? Cost?

Justyna Rapacz: Wave springs are the go-to compression spring when space is a constraint; however, they are not the ideal solution for applications with large travel and/or accompanied by a relatively high load requirement. Wave springs are designed for compression only, so in applications where extension or torsion is required, an alternative spring should be specified.

Cost-wise, wave springs can save you money when taking the entire assembly under consideration. Wave springs can optimize space in the assembly by providing the same spring force in a smaller space, resulting in an overall decrease in assembly size, weight, production time, and material cost. While wave springs may potentially have a higher piece price than coil springs, overall cost savings may be seen when designing a wave spring into your application.

DN: How does the choice of material affect the performance of the spring?

Justyna Rapacz: Selecting the right material is critical for optimal spring performance. There are several factors to consider during spring material selection, such as operating environment, cycle life, and budget. Standard wave springs are available in carbon steel and 17-7 stainless steel.

|

DN: What is your forecast for the increased use of wave springs in the future?

Justyna Rapacz: As the world around us gets smaller and smaller, space is quickly becoming a premium. Wave springs offer engineers the space-saving solution they need to meet the demand of designing modern-day, compact technology.

About the Author(s)

You May Also Like