No (Product Development) Vacancy

What can you do when there is no space available for your design?

July 18, 2023

Design is about far more than requirements. Designers also need to consider the many constraints imposed on the solution. It could be power requirements, memory limits, or weight. Another one is space. We are encouraged to think outside of the box, but we need to keep things inside the box!

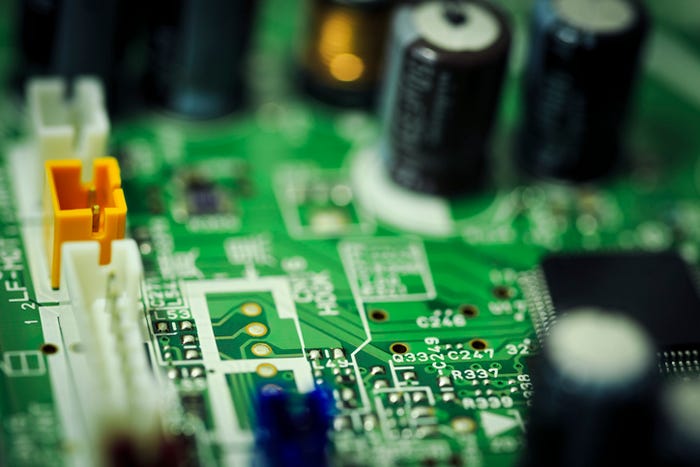

Early in my career I was leading a project to add functionality to an existing design. We had an established space claim and no room to grow. The added functionality dictated more electrical components on the circuit board. It was a high-power situation, so we needed to cool the electronics. My electrical engineer created the schematic and selected components for use. The designer laid out the board, according to our design standards.

All was well until we looked at the size of the board to be integrated. It was far too big! We looked at creating a two-board design, with a pin interconnect. This made the overall volume bigger, but the footprint was improved. Still not an acceptable answer.

From my manufacturing engineering background (I am a mechanical engineer who had some electrical understanding at the time), I was aware of SIPs (single in-line packages). This combines several components into one unit. We laid out the board again using this idea. The board was smaller and yet simple.

While the electrical engineer knew about the design elements, he was not aware of practical components. Together, we solved the space dilemma that previously had us stumped.

In another case, we had a more open-ended design situation. With this clean sheet of paper, we could do whatever we wanted. As the design evolved, we had a separate group managing the space claim model. We could perform our design within the bubble of space we had assigned. To have space assigned, we needed to ask for it.

Unfortunately for my team, we inherited design effort from another group. They worked on things they were interested in, but they did not dig into other areas. One important functionality had not been designed or even concepted yet. Very hard to ask for space without an idea behind it. When we recognized the lack of any space defined, most of the other groups had already addressed their needs. This meant we were stuck with the leftovers. A design requirement remained, but realistically no space was available to accomplish it.

As I talked with the designer responsible for this area, we knew we were in trouble. We went beyond having a constraint. We needed to be creative about finding space for our solution. At this point, we needed to act quickly in case other teams needed more space and our situation would get more difficult.

The design was for an actuated door. The door existed but space for the motor and gear box did not. Could we mount it away from the door, and have a long actuator arm? This would weigh more, but we might be able to sneak around the space other people had consumed. Could we mount on the door itself? This meant the door would weigh even more, making it harder to move and harder to find space. Could we locate ourselves on the other side of the door, and pull it open instead of pushing it open? While there seemed to be room here, we really did not know about the space considerations involved.

This brainstorming allowed us to have discussions with other groups and to find some trade-offs that would allow for a design solution. Sometimes, sharing bad ideas helps others open up to work with us for a better overall solution. It was the case for this situation.

Balancing Constraints During Product Development

The point of both of these stories is that constraints can really drive the final solution. Designers need to understand them and work to discover them. Some may be stated up front, but others may be unstated. A good designer needs to balance the requirements, as we talked about in our previous column, but also needs to understand and balance the constraints involved.

What challenging constraint have you overcome in your design experience? Is there one you are currently facing? How did you or will you get it resolved? Would love to hear back from you on this critical design topic. It may even help you come up with new ideas for your current design!

About the Author(s)

You May Also Like