How CMOs Add Value for OEM Partners During a Crisis

OEMs should choose CMO partners that can help scale to market fluctuations, adjust production schedules, navigate supply chain disruptions, and more, according to a CMO expert.

December 9, 2020

The COVID-19 pandemic has presented medical device original equipment manufacturers (OEMs) with several challenges pertaining to production, supply chains, market demand, and more. Carl Savage, vice president, business management, for MICRO, a full-service contract manufacturer, answered a few questions for MD+DI on how contract manufacturing organizations (CMOs) can help OEMs address these challenges and others. According to Savage, the company looks for novel ways to improve product design, development, and manufacturing.

Given today’s challenging times, why are partnerships between CMOs and OEMs more crucial than ever for ensuring success?

Savage: A successful partnership between a CMO and an OEM is one that is based on mutual collaboration and trust. An experienced CMO can help OEMs innovate, get their products to market faster, optimize costs, and mitigate risk. The COVID-19 health crisis has created a number of challenges for medical device manufacturers. Elective procedures have dramatically decreased as hospitals focus on COVID-19 and demand for products across specialties has taken a real hit. These hurdles are likely to continue for the near term and recovery will be slow. Given the uncertainty of the market, it is more important than ever that OEMs choose the right CMO partner who can help scale to market fluctuations, adjust production schedules, navigate supply-chain disruptions, and maintain inventories. While the hurdles are real, there also have been opportunities to establish new best practices during these unprecedented times. Transparency and communication have always been important components of a successful CMO-OEM partnership, but they have now taken on even greater significance during the pandemic. Manufacturers that can lead their companies and customers through the uncertainty successfully will be better equipped to handle challenges in the future.

What are some best practices you have implemented during the coronavirus pandemic?

Savage: Early on we worked to ensure that the disruptions to our operations were as minimal as possible. Our company has always prided itself as having an “all hands-on deck” business philosophy, and this has been no different during the pandemic. We quickly established best practices for essential workers who needed to be at our manufacturing facilities and on the production floor to ensure the work environment was as safe as possible. We enlisted feedback from employees at every level and got some really solid and valuable insights and ideas, much of which we implemented. It is critical that companies engage and communicate with employees and customers frequently during a crisis. Again it goes back to transparency and trust. Organizations that exhibit those characteristics consistently are nimble, solution-oriented, and well positioned for future success.

Generally speaking, what advantages do CMOs offer OEMs that choose to outsource production?

Savage: Outsourcing manufacturing operations has many benefits for OEMs and is a common occurrence across the medical device industry. An experienced CMO partner can perform more labor-intensive operations that typically require capital investment, large inventories, and a skilled workforce. A full-service CMO has the necessary expertise to streamline production and optimize development cycles. As such, a strategic CMO partner allows OEMs to focus on core competencies—commercial operations, sales and marketing, and business development, for example—and outsource the operations that fall outside the company’s primary areas of expertise. The result is a competitive advantage because an experienced CMO is often more adept at understanding how to reduce manufacturing complexities and improve processes and operations. CMOs with a deep knowledge base typically have the flexibility to scale manufacturing operations to meet production and volume adjustments. An experienced CMO also understands the regulatory complexities of the market and can ensure that safety and quality requirements are met. The bottom line is CMO-OEM collaborations maximize each partner’s complementary capabilities. When done correctly, outsourcing manufacturing operations helps OEMs minimize risk and maximize profitability.

What are the scenarios where outsourcing could introduce risks and how can outsource partners help mitigate those?

Savage: In our experience, risks can sometimes be introduced when OEMs outsource production of individual components or parts to a number of different sub-suppliers. Doing so could compromise functionality of the end-product, and it might even increase costs inadvertently if the product does fail to perform once it is on the market. Correcting a mistake of this nature can be costly downstream.

Can you talk about a project that illustrated the importance of a strategic partnership?

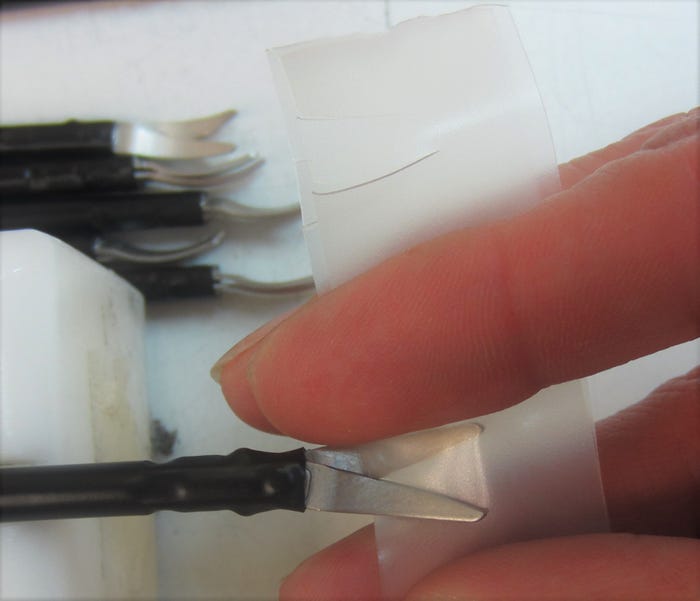

Savage: From time to time an OEM will attempt to use different sub-suppliers to build individual components rather than a full-service vendor with production and assembly capabilities, with the goal to reduce costs. We experienced this situation when a customer approached us to produce micro scissor blades for an endoscopic surgical device. The customer held a firm belief that using sub-suppliers would decrease costs associated with labor and product cycle times. We advised the customer that this approach could compromise the product’s ability to perform or function properly given the complexity of the device.

With 30 years of hands-on knowledge and experience producing functional single-use laparoscopic scissor assemblies, we knew that producing a scissor blade as a stand-alone component did not have a high likelihood of yielding a successfully functional product. We created a prototype that confirmed our suspicions and advised the customer that we would only take on the project if we could fully assemble the device because we felt that functionality was at risk on a stand-alone scissor component. The customer did not heed our advice and we mutually agreed to part ways on that particular project. Fast forward, the customer was not successful at creating an optimally functioning product with the use of sub-suppliers and eventually re-engaged with us for full assembly of the product. The product did have a successful market launch; however, the customer learned a lesson that was costly in terms of both time and money.

Bottom line, what are the critical success factors for every successful CMO-OEM partnership?

Savage: It is important that both partners fully understand each other’s capabilities and expertise. OEMs that choose to outsource should select a CMO partner with the right level of experience for the project and the collaboration should begin with an agreement on the terms and parameters of the project. CMOs should also understand an OEM’s downstream goals, which will help the contract manufacturer identify the most effective and efficient way to produce high quality, compliant products across the development continuum. Everything goes back to consistent, open communication.

You May Also Like