Three new commercial systems unveiled at IMTS combine Optomec's LENS blown powder metal AM print engine technology with Fryer Machine Systems' conventional compact mill CNC vertical milling platforms. They're priced far below typical hybrid systems.

September 16, 2016

Last year Optomec revealed the result of its America Makes project to combine its LENS metal additive manufacturing (AM) technology with CNC functions at the RAPID 2015 show in Long Beach, Calif. That project developed a low-cost LENS print engine that can be installed on most machine tools to form a hybrid system.

At this week's International Manufacturing Technology Show (IMTS) in Chicago, the company introduced three new commercial systems combining LENS blown powder metal AM print engine technology with conventional compact mill CNC vertical milling platforms from Fryer Machine Systems. The new machine tool series is priced far below industry standard pricing for such hybrid systems, starting at $249,500 for the basic LENS 3D Metal Additive System, an additive-only product.

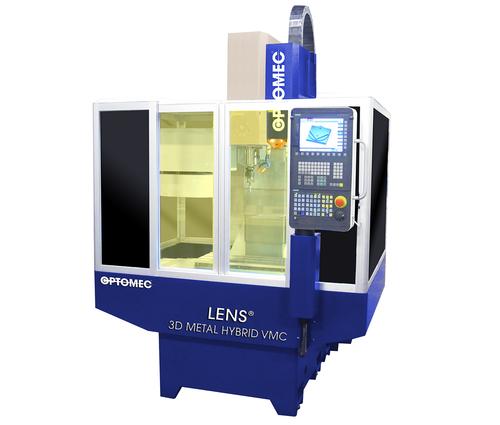

Three new commercial systems combining Optomec's LENS blown powder metal AM print engine technology with conventional compact mill CNC vertical milling platforms from Fryer Machine Systems are priced far below typical hybrid systems. The standard LENS 3D Metal Hybrid VMC System, shown here, starts at $299,500. (Source: Optomec)

This additive-only LENS 3D Metal Additive System has a 20 inch x 14 inch x 20 inch work envelope, a 12 inch x 24 inch table, a 500W LENS print engine, CDRH Class 1 laser safe enclosure, a powder feeder, local shield gas, and a Siemens controller. Next in the series is the standard LENS 3D Metal Hybrid VMC System, which combines both additive and subtractive operations on the same machine, priced starting at $299,500. It has the same size table, plus a 20 inch x 14 inch x 20 inch milling work envelope, a 14 inch x 20 inch x 14 inch additive work envelope, a 500W fiber LENS print engine, and an 8-station ATC/60-8,000 rpm spindle.

At the IMTS press conference, Optomec said the third machine, the LENS 3D Metal Hybrid VMC Inert System, is the first of its kind for metal working because it provides an atmosphere-controlled environment to extend hybrid manufacturing capabilities for reactive metals and aluminum. By replacing the CNC machine's upper enclosure with an Optomec proprietary hermetically sealed chamber and gas purification system, the 3D Metal Hybrid VMC Insert System can maintain oxygen and moisture levels under 40 ppm.

3D Printing's Brave New World. Ann Thryft will lead a panel discussion on one of the hottest topics in manufacturing: 3D printing. Come hear "3D Printing: The Brave New World of Manufacturing" at the Embedded Systems Conference, Sept. 21-22, 2016 in Minneapolis. Register here for the event, hosted by Design News’ parent company, UBM.

3D Printing's Brave New World. Ann Thryft will lead a panel discussion on one of the hottest topics in manufacturing: 3D printing. Come hear "3D Printing: The Brave New World of Manufacturing" at the Embedded Systems Conference, Sept. 21-22, 2016 in Minneapolis. Register here for the event, hosted by Design News’ parent company, UBM.

Its basic specs are the same as the second machine but with a 500W LENS print engine and the hermetically sealed chamber and gas purification system. A 15-inch antechamber lets operators move parts in and out of the system without breaking atmosphere. Pricing for this machine starts at $399,500. First customer shipments for all three will start in the first quarter of 2017.

Used for many years in military and aerospace applications for low-volume manufacturing and in-service product repair, the blown powder LENS metal AM technology in production-grade standalone 3D printers was originally developed by Sandia National Labs. Optomec's existing systems, such as the 850R for production and the 450 for education, are based on its own automation platforms. Forming a hybrid system by installing the relatively low-cost modular print engine on a machine tool can drastically reduce the amount of time it takes to machine parts -- as well as materials costs -- because printing and finishing can be done in one setup.

READ MORE ARTICLES ON 3D PRINTING COMPOSITES:

Like the America Makes project and other commercialization efforts, Optomec has said its goal in releasing the LENS Machine Tool Series is to speed up the use of metals AM in US industry, and broaden the use of production-grade metal additive manufacturing by making the technology more affordable and accessible. A second step announced at IMTS is the integration by Fraser Machine Systems of Optomec's LENS technology into its new LaserFab 3D hybrid VMCs (Vertical Machining Centers). Starting at $350,000, these machines cost less than half the price of comparable hybrid metal systems.

Standard features include a 1.5-second 24-tool ATC (Automatic Tool Changer), a 15,000 rpm inline spindle with a 30,000 rpm option, a high-torque 30 hp motor, a super-fast 1,900 IPM rapid feed rate, roller-type linear ways, and heavy-duty FEA-designed castings. The LaserFab can print and finish machine parts to a tolerance of only four microns.

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 29 years, covering manufacturing materials & processes, alternative energy, and robotics. In the past, she's also written about machine vision and all kinds of communications.

About the Author(s)

You May Also Like