Study Says Humans First, AI Last for Semiconductor Manufacturing

Researchers say hybrid approach can cut process development time and reduce costs for semiconductor manufacturing.

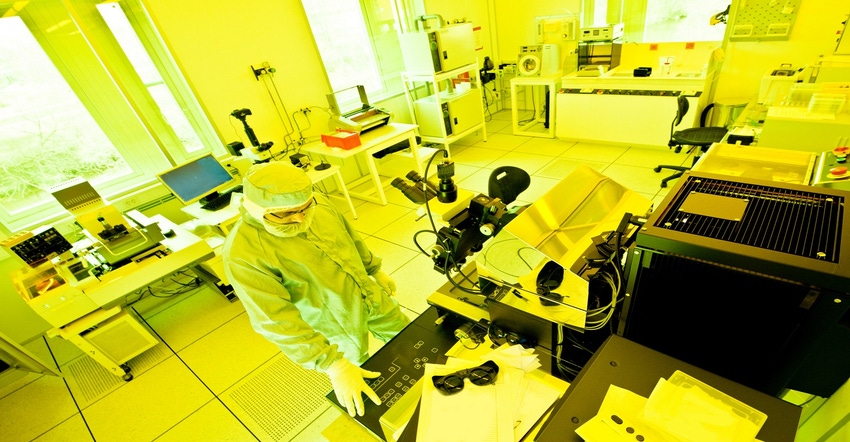

AI (Artificial Intelligence) is being looked at for many manufacturing processes, but what is its potential impact on a key process─semiconductor manufacturing? In a new study, Lam Research Corp. examined the potential for the use of artificial intelligence (AI) in process development for chip fabrication, today a human-driven step that is essential for the mass production of every new advanced semiconductor in the world.

The study, recently published in the journal Nature, was intended to explore reducing development costs and accelerate the pace of innovation to meet the increasing demand for next-generation chips. The study found that a “human first, computer last” approach can reach process engineering targets dramatically faster, and at half the cost compared to today’s semiconductor manufacturing approach.

In the study, Lam researchers pitted talented process engineers head-to-head against AI-enabled computer algorithms in the study.

Complex Process Steps

In current semiconductor manufacturing, for every chip or transistor design engineers need to create a detailed serie/s of procedures that outline the specific parameters and permutations needed for each process step. Hundreds of steps are required to build these nanometer-sized devices on a silicon wafer. Process steps typically include multiple instances of depositing thin layers of materials onto silicon wafers and etching away excess material with atomic-scale precision. This essential phase of semiconductor manufacturing development is currently done by human engineers, largely using their intuition and a “trial and error” approach. The unique parameters of every chip make process development laborious, time-intensive, and costly.

In the Lam study, machine and human participants competed to create a targeted process semiconductor manufacturing development procedure at the lowest cost, weighing various factors associated with test batches, metrology and overhead expenses. The study concluded that while humans excelled in solving challenging and out-of-the-box problems, a hybrid human first, computer last strategy can help address the tedious aspects of process development and, ultimately, speed up process engineering innovation for semiconductor manufacturing.

Integrating AI

“Our research showed that while engineering talent remains essential to innovation, process engineering costs can be reduced by 50% by integrating AI at the right stage and with the right data,” said Rick Gottscho, executive vice president and strategic advisor to the CEO – Innovation Ecosystem at Lam Research and co-author of the study. “The study provides a prescriptive approach for bringing together the best of human-led engineering and the best of what data science and machines offer to create a combination that performs better than either one alone. If realized, this hybrid approach can lead to significant savings in both dollars and engineering time for the industry.”

Lam is now incorporating the key learnings from the study into its development operation for semiconductor manufacturing. The Lam study provides initial guidance on how to successfully integrate human knowledge, skill and experience with AI’s ability to rapidly assess numerous possible combinations in process engineering.

Spencer Chin is a Senior Editor for Design News covering the electronics beat. He has many years of experience covering developments in components, semiconductors, subsystems, power, and other facets of electronics from both a business/supply-chain and technology perspective. He can be reached at [email protected].

About the Author(s)

You May Also Like