How to Build Better Electronics With Cables and Connectors

Autonomous vehicles and infotainment electronics require careful selection of optimal cables and connectors.

February 23, 2021

Today’s automotive In-Vehicle Infotainment (IVI) systems are a marvel to behold. Some pundits have described them as smartphones on wheels as they contain similar features such as high-definition touch screens, voice control, and response, hands-free operation, GPS navigation, wireless connectivity, high-speed connectors, and more.

To enable all these marvels, automobiles are now full of electronic chip and board-level systems communicating via high-speed networks and buses. Unfortunately, many designers of these systems - be it for infotainment or some level of autonomous driving – forget the critical importance of selecting and implementing the optimal connectors and cables. Each of the many electronic systems has its own connector and related cabling requirements.

Modern vehicles consist of hundreds of sophisticated sensors, signal conditioning circuits, processors, and other electronics that are all connected with cables, wires, and harnesses. Each of these connections required the right kind of connectors to meet high-speed signal and data bandwidth requirements while consuming as little power as possible. Small size and the capability to withstand harsh automotive environments are also needed.

The infotainment subsystem offers a good example of the complexity of selecting and implementing the optimal connector for a variety of cables. Consider the case of FFC (Flexible Flat Cable) and FPC (Flexible Printed Circuit) - where components are built onto a flexible cable material. Both refer to a variety of extremely thin flat electrical cable types that are the staple of high-density electronic packages like laptops and cell phones.

Other wiring and connector types are needed for RF, USB, low-voltage differential signaling (LVDS), general wire harnesses, and coaxial cables.

On the input/output portion of the infotainment, modules are a variety of connector and cable combinations. For example, high-speed data (HSD) connectors are used for vehicle infotainment modules as well as cameras, consumer ports, and display units. These connectors can be used in combination with protocols 1 and 4 channel LVDS, IEEE 1394, eMOST, and USB 2.0.

Common input/output (I/O) connectors for infotainment systems include HSD, FAKRA, USB Micro B, USB Mini B, HDMI, Hybrid Cable, and even Optic Fiber Cable.

To learn more about building better products by selecting the optimal automotive connectors and cables, Design News reached out to Gary Manchester, Director of Advanced Technology and Market Development at Molex. What follows is an edited version of that discussion.

Design News: Why is there a trend toward high-speed connectors and cables in today’s automotive electronics?

Gary Manchester: As cars begin to implement more ADAS applications, the need for data and data analysis grows quickly. In addition, as cars become more automated, the demand for more infotainment functions will increase. After all, both drivers and passengers will be less concerned with the task of actually driving the vehicle. The increase in infotainment features will also lead to an increase in data traffic on the internal and external car networks. Higher speed channels and the resulting need for high-speed connectors and cables will further be driven by safety regulations, safety requirements, and the demands of 5G.

Design News: What are a few specific automotive applications that require different types of high-speed connectors.

Gary Manchester: High-speed Serializer/Deserializer (SerDes) driven applications to continue to grow in popularity. SerDes is a pair of functional blocks commonly used in high-speed communications techniques to compensate for limited input and output cables and capabilities.

SerDes applications are used for cameras, sensor fusions, displays, transmission control units (TCUs), and engine control units (ECUs) that are doing data aggregation. Molex is seeing demand for multi-gig interfaces up to 15 Gbs. Further, we anticipate near-term car architectures of 25 Gbs or more. Today, standard organizations that fill these high-speed connector and cabling needs include the IEEE, ASA, MIPI, and VESA. Proprietary technologies include FPD Link and GMSL.

Design News: What tips can you share with engineers and product developers on how best to include connectors and cables into their designs?

Gary Manchester: Here are three steps that will help:

1) When selecting the optimal interconnect technology, pay particular attention to scalability. There is no question that increases in bandwidth will be needed in the future. Further, engineers and product developers must plan to meet these increases in bandwidth and data needs with little or no cost impact.

2) When looking to decide which cables satisfy various applications, don’t look for the 'one size fits all'. For example, just because a standard says you must support 15 meters with 4 inline connections, don’t spec that cable for the hundreds of links that will not need inline connections and have run shorter than 15 meters. Make sure each connector and cable pairs meet the needs at hand.

3) Finally, bring your connector supplier into the selection discussion early in the product design process. Millions of dollars are spent on addressing channel performance issues because of signal integrity (SI) or electromagnetic interference (EMI) issues that are not recognized until late in the product development process.

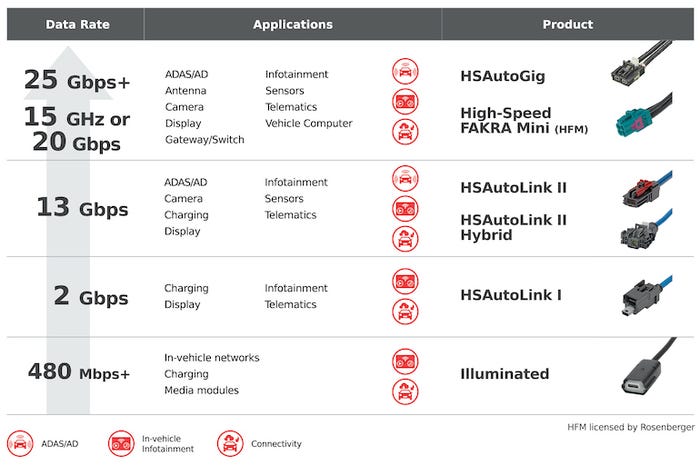

Design News: Thank you, Gary. I’d like to add a few clarifying remarks related to the useful image below. It’s important for designers to appreciate that various vendors use different nomenclature to describe their high-speed serial buses. For example, Molex supports high-speed data for automotive with a 5-pin shielded connector that is called HSAutoLink. This data bus is also called USCAR USB and meets automotive requirements for Universal Serial Bus (USB) 2.0.

The connector vendor also provides connectivity in this family for Low Voltage Differential Signaling (LVDS), IEEE 1394 for automotive, FlexRay (ISO 10681-1:2010), Ethernet, and MOST. FlexRay, now ISO 10681, was developed by a consortium of automotive companies to provide a higher-speed bus than the traditional CAN bus used in automotive. The packaged assembly deploys an economical five-pin shielded connector system from the consumer market that has been ruggedized to meet automakers’ mechanical requirements and to bring USB and other technologies to vehicle information and entertainment systems.

Finally, antennas and amplifiers on the exterior of the vehicle are connected via coaxial cable using FAKRA (Fachkreis Automobil, originally a German standard, which means literally "Automobile Expert Group") compatible connectors. These connectors, based on the SubMiniature version B (SMB) connector type (coaxial RF connectors from the 1960s), are used to connect coaxial cable to receivers/transceivers located in the vehicle for GPS, satellite radio, cellular communications, and some FM signals.

|

Molex high-speed networking cable and connector offering for in-vehicle infotainment and ADAS/AD applications. |

John Blyler is a Design News senior editor, covering the electronics and advanced manufacturing spaces. With a BS in Engineering Physics and an MS in Electrical Engineering, he has years of hardware-software-network systems experience as an editor and engineer within the advanced manufacturing, IoT and semiconductor industries. John has co-authored books related to system engineering and electronics for IEEE, Wiley, and Elsevier.

About the Author(s)

You May Also Like