2 Tools to Avoid Costly System Maintenance and Unexpected Testing

Testing, an important part of maintenance, requires new tools in the age of the IoT.

May 5, 2021

Testing is an important part of maintenance. But few people think about the maintenance of engineered systems until a failure occurs. Maintenance strategies have typically consisted of a combination of time-based and run-to-failure techniques. In other words, these strategies relied largely on human observation methods to detect maintenance failures or used empirically captured data to predict in a general sense when a failure might occur.

Those approaches to maintenance are changing with the growth of smart autonomous systems in the Internet-of-Things (IoT) world. For example, factories are now using near real-time sensors, processors, and edge-cloud computing to determine when bearings will fail on a conveyor-belt production chain. This approach is known as conditioned-based maintenance or CbM.

The goal of condition-based maintenance is to ensure each industrial, military, or even consumer asset is available when needed and has been properly maintained to avoid failure. Achieving this goal in an economical fashion requires that maintenance is not performed too soon or too late but rather to detect potential failures just before they might occur.

A working conditioned-based maintenance strategy involves capturing data from a variety of sources, including sensors, mobile diagnostic tools, and other data acquisition devices. The captured and digitized data is aggregated, analyzed, and used to make good decisions and predictive actions using the appropriate resources.

Condition-based vs. Predictive Maintenance

Condition-based and predictive maintenance (CbM/PdM) are both maintenance approaches to prevent failures before they happen. As such, they are both forms of proactive maintenance and are designed to increase reliability and decrease downtime.

The main difference between them is the way in which maintenance is measured. Condition-based maintenance relies heavily on embedded real-time sensor measurements such as temperature, vibration, noise, and the like. When an equipment parameter reaches an unacceptable level, an alert is sent, and maintenance workers are dispatched.

Conversely, predictive maintenance relies on formulas and schedules in addition to sensor measurements. Maintenance work is then performed based on a scheduled, predictable basis.

People sometimes confuse predictive maintenance (PdM) and condition monitoring (CdM). Both of these terms are maintenance techniques and tools within a condition-based maintenance (CBM) strategy. These techniques and tools are used to detect symptoms of potential failures of equipment; they are not strategies themselves.

Maintenance Tools

For conditioned-based maintenance to work requires accurate, reliable, and often ruggedized condition monitoring systems. Industrial applications depend upon a combination of technologies and design considerations to capture and convert critical signals that can be used to make timely decisions, enabling useful diagnostic and predictive maintenance strategies.

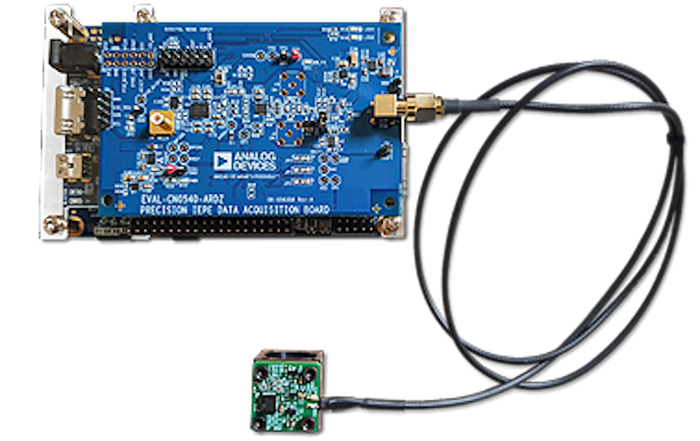

For example, Analog Devices recently announced a condition-based monitoring platform that combines sensor and signal chain technologies controlled by embedded software and used to accelerate sensor data collection. Such processed data can then be used for asset evaluation and diagnostic actions.

In addition to embedded hardware and software data acquisition boards, another useful tool in CbM is the creation of a digital twin, such as those provided by Ansys.

If an asset is required to remain fielded for an overly extended period, its digital twin can predict when, how, and why the asset will need to be maintained, avoiding potentially unnecessary time-based scheduling.

“The impact of digital twins goes beyond the asset and extends to logistics,” explained Robert Weiss, Ansys consultant and EVP & GM, Lockheed Martin Advanced Development Programs (Skunk Works) (Ret.).” This has significant implications for mission readiness if an asset deploys to remote or hazardous locations. By understanding the condition of any given asset at any given time, sustainment leaders can anticipate maintenance requirements, ensuring the right components and personnel are in the right place at the right time, making real the concept of condition-based maintenance plus (CbM+).”

CBM+ is built upon reliability-centered maintenance (RCM) and condition-based maintenance (CbM) to enhance safety, increase maintenance efficiency, improve availability, and ensure environmental integrity.

John Blyler is a Design News senior editor, covering the electronics and advanced manufacturing spaces. With a BS in Engineering Physics and an MS in Electrical Engineering, he has years of hardware-software-network systems experience as an editor and engineer within the advanced manufacturing, IoT and semiconductor industries. John has co-authored books related to system engineering and electronics for IEEE, Wiley, and Elsevier.

About the Author(s)

You May Also Like