DN Insight: What Rare Earth Shortages Mean for Engineers, Part 4

April 30, 2012

When neodymium-based magnets first hit the scene, they offered high flux but over a very limited temperature range. Modifications to the alloys, including the addition of dysprosium, ultimately yielded powerful, thermally robust magnets that enabled the development of motors with far greater torque density and thermal range than possible with traditional materials like aluminum nickel cobalt (AlNiCo) and ferroceramics.

Suddenly, engineers had the luxury of motors that were many times smaller and lighter than their conventional counterparts. At the same time, rare earth magnets remained cost-effective courtesy of Chinese suppliers, who soon dominated the market.

In part four of this five-part design series, we look at how focusing flux in three dimensions allows ferrite-magnet motors to achieve performance and form factors competitive with rare earth designs. (Read part 1 here, part 2 here, and part 3 here.)

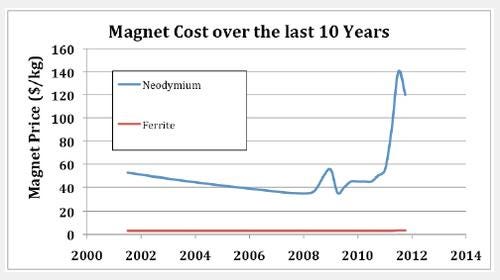

Everything was just dandy until around 2008, when speculators began hoarding materials, causing a supply contraction that drove up prices dramatically (see figure 1). What had been a viable industrial material became exorbitantly priced. The question changed from, "What can we do with rare earth magnets?" to "What can we do without them?"

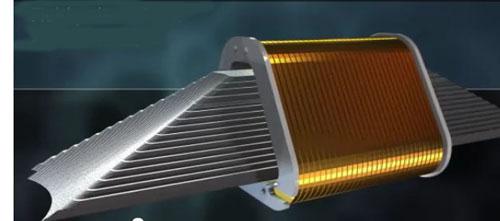

The answer, according to NovaTorque Inc., is "plenty." They developed an axial motor design that focuses flux in three dimensions, rather than the two dimensions of conventional radial designs. The result is an economical ferrite-magnet motor that delivers torque and efficiency comparable to that of rare earth versions, in a similar frame size.

Radial air-gap permanent-magnet motors consist of a radially symmetric rotor nested in a cylindrical stator, with an air gap between the two. The rotor incorporates permanent magnets, either on the surface or the interior. The stator features electromagnets consisting of copper windings energized in a specific sequence by the drive to form alternating flux patterns. Both rotor magnets and stator windings are aligned with the z-axis of the motor, which causes the flux interaction -- and, hence, force exerted on the rotor -- to take place in two dimensions. When the windings are energized, the stator flux Φs interacts with the flux ΦR of the rotor magnets to exert a force on the rotor, causing it to turn.

About the Author(s)

You May Also Like