New Design Apps for a New World

March 24, 2015

New design applications are popping up everywhere. From advanced touchscreen applications to new ways for finding lighter and stronger materials, design applications are springing up to improve design productivity. Each one is created to help the design engineer survive and thrive in an environment of ever-increasing speed-to-market.

Multi-touch screens with gesture control are showing up on large displays. Plus, touchscreens on phones are becoming more detailed. They now respond to a finer touch. The image can be enlarged for more detailed manipulation on a mobile device. 2D sketching is now more sophisticated and easier to integrate into 3D CAD, and enhanced PLM systems are helping with materials selection and collaboration.

In some cases such as CAD, the new applications have familiar but improved technology; in other cases such as design collaboration tools, the emerging technology is pushing the design process into new directions to meet business requirements.

Productivity in Design

Here's a way to trade designs with team members who are not all using the same software: Altium Limited has created 3D PDFs that allow anyone on the project team to view the printed circuit board (PCB) in full 3D without the need for specialized software. In another effort to improve design productivity, Altium has added design re-use capabilities, specifically for pads and vias on PCBs. "Our customers tell us exactly what you would expect a customer to tell you: they're concerned about time and cost," David Read, director of product marketing at Altium Limited, told Design News. "They need to complete their projects faster and for less money."

Another area where Altium is trying to improve design productivity is in the market push to Internet of Things (IoT) connectivity. "There is a race to be the first to connect a product. This is true for every product imaginable," said Read. "Those who get their products to market first are in a great position." Read notes that to win the race, the efficiency of the entire design team is critical. "We worked on a number of product designs for IoT. Many of the productivity improvements we've made in Altium Designer 15 stem from that experience."

Touch Screens Big and Small

Siemens PLM looked at advances in touch screens as a way to improve the design engineer's productivity. It proceeded along two completely opposite areas of touch. One approach is to add flexibility to the small screen, while the other is to look at large-area touch, particularly for presentations. "We took a step back and looked at multi-touch and gesture control to drive the design applications," Paul Brown, senior market director at Siemens PLM, told Design News. "We introduced a new touch application to the large screen - a touch device that recognizes gesture."

MORE FROM DESIGN NEWS: App Lightens Up Your Design's Materials

The large multi-touch screen allows multiple users to manipulate an image simultaneously. "We actually got everyone on the design team around the screen, and people were poking on the image," said Brown. "The large screen is not just for display. You can actual move images over and get real usage in the design process."

The importance of touch in design applications is continuing with mobile devices, so Siemens has also improved touch capabilities on these tools. "We see an increased use in [design with] touch with smartphones and tablets," said Brown. "It's the way people want to interact. In five-year's time, the mouse and keyboard will be gone. So we've introduced improved touch applications to the 10-inch device and the 108-inch screen."

Seamless Move from 2D to 3D

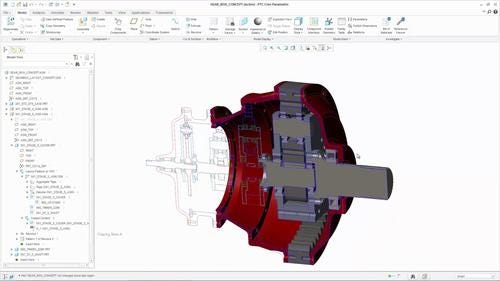

The design of a product often begins life as a 2D sketch. As the design develops, it moves into 3D for advanced work. "Design engineers find that creating the mechanical design concept is easier in 2D," Paul Sagar, director of product management for MCAD at PTC, told Design News. "If they want to iterate on an existing design, it's often in 2D." Sagar noted that PTC's approach is to create role-based apps. "We want to develop the right app for the right person at the right time," he said.

PTC sees a common pattern of product concepts getting developed in 2D and then moving to 3D for advances. "If you're a company doing conceptual parts and you want to work in 2D, we have Creo in a 2D environment," said Sagar. "It lets you lay out your design in 2D." In moving to the next stage of design, PTC converts the 2D design concept to 3D. "In most cases you have to re-do everything by scratch to get it to 3D," said Sagar. "We enable you to take the 2D info and leverage that to build the rich 3D engineering data. You can continue to iterate the design concept while also seeing it developed in the full 3D rich data form."

Quick Search for Lighter, Stronger Materials

Energy efficiency is critical and most industries, from automotive, with its need to prepare for increasingly stringent gas mileage standards, to aerospace, with its continual need for improved fuel efficiency. A big part of the drive for efficiency comes down to finding lighter materials that match the strength of steel.

MORE FROM DESIGN NEWS: Engineering Apps You Need to Know About

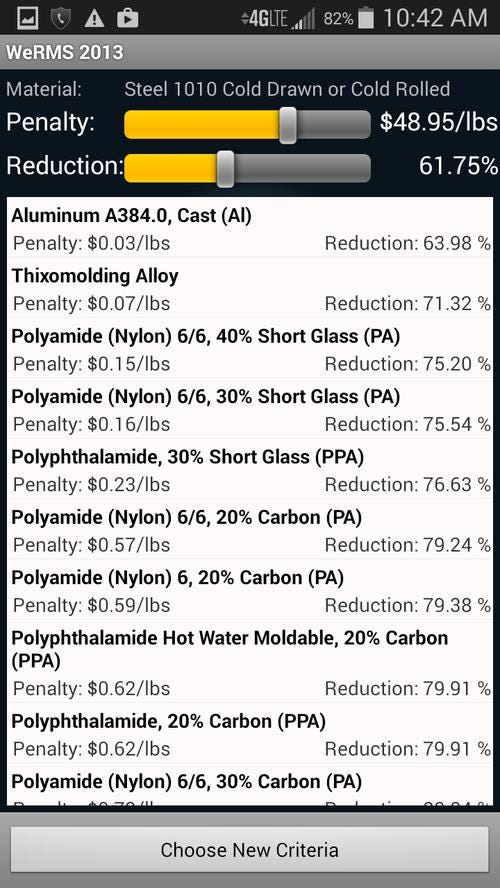

Munro and Associates created the Weight Reduction Material Selector (WeRMS) applications to address this need. "WeRMS can help the design engineer to very, very quickly come up with lighter weight materials that fit the parameters that you input based on the structural properties you require," Alistair Munro, director of business development for Munro & Associates, told Design News. "Tt reduces the time needed for comparisons by a huge order of magnitude. It essentially takes an exercise that would take you several hours - if not days - and reduces it to seconds."

As well as positioning it as a productivity tool for the design process, Munro sees value in WeRMS in the boardroom.. "If you're in a design review or brainstorming session with lightweighting as the focus, and you quickly input the parameters into your phone and then suddenly blurt out ideas and comparisons, everyone will swivel around and stare at you like you're an alien. No one can spit out answers that specific and realistic off the top of their head," said Munro. "It's definitely something you can use to impress your boss and your peers."

Design Collaboration Advances

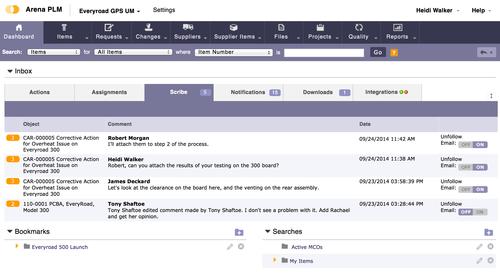

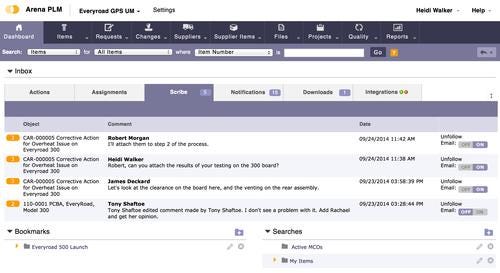

We're not working in cubicles any longer; we're working in "cable." So says Steve Chalgren, vice president of product management and strategy at Arena Solutions. Chalgren sees collaboration tools as the necessary technology to make a successful move to the digital design and manufacturing chain. "We've created spaces designed for specifically for design collaboration," Chalgren told Design News. "We create Arena Scribe to collaborate, not just in silos and departments, but straight through the design stream."

Part of the growing need for collaboration is that more people at different levels are involved in the design process. "You no longer throw it over the wall," said Chalgren. "People who weren't included before are now included early." Chalgren sees the solution in a collaboration platform where someone from corporate strategy or marketing can see what's going on. "The goal is to let people follow the design like Twitter," said Chalgren. "They can come in from all over the world at any time and look at the history of the design. It breaks down the silos and lets design teams come up with ingenious ideas much faster."

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine, Chile Pepper.

About the Author(s)

You May Also Like