October 21, 2015

The auto industry has long turned to outside design teams to speed the creation of new vehicle models. In the last few years, the practice of bringing in outside design suppliers has been spreading to other industries, from electronics to aerospace to defense. While the electronics industry has long outsourced its manufacturing, it now routinely uses original design manufacturers (ODMs) in Asia to complete the designs for laptops as well as manufacture them.

Outside resources offer fresh ideas and help balance cyclical design needs. It’s easier – and less expensive – to turn off a vendor’s spigot during slow times rather than laying off experienced and talented employees. Given this reality, the use of outside design is increasing.

“There has absolutely been a rising trend for OEMs and Tier One vendors to outsource more of their design work, especially since around 2008,” Alistair Munro, director of business development at Munro and Associates, a full-service design and engineering consultancy, told Design News. “The reason for this trend is simple; it boils down to lower cost and shared risk.”

Compelling Reasons for Outside Design

Munro noted that hiring an external well-respected design company offers the advantage of a greater pool of design engineers with varied experience while simultaneously decreasing the internal cost of design and engineering. “Outside design eliminates employee medical and benefits costs and the downtime costs when design personnel are not essential,” said Munro. “You also get to share your risk with an external company when it comes to design errors.”

READ MORE ARTICLES ON DESIGN SOFTWARE:

If the outside design company also happens to be the manufacturer of your product, that’s even better, according to Munro. Design and manufacturing are common co-functions for laptops and cell phones, for example. “This arrangement is cheaper from a procurement standpoint,” said Munro. “There are a lot fewer people and places to point the proverbial finger if something goes wrong.”

While laptop and cell phone design is commonly outsourced to ODMs, most products in the electronics industry are designed in-house because the need for rapid design doesn’t provide easy back and forth between companies. Plus, stiff competition precludes sharing designs with outside firms.

Medical manufacturers are also less likely to use outside design houses. “The medical industry tends to outsource much less because of compliance and quality issues,” said Munro.

Tools to Facilitate Outside Design

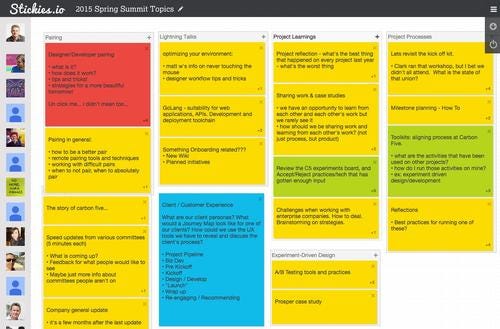

While tools for design collaboration were skimpy a decade ago, there is now a plethora of collaborative software that supports shared design. “You can use CAD, PLM, or Mapping and Analytical tools such as Design Profit,” said Munro. “But it is still important to have those face-to-face design reviews with the whole design team in order to achieve complete compliance and root out potential conflicts early.”

Face-to-face isn’t always easy to facilitate, especially when your design partner is half a world away, thus facilitating web and videoconferencing tools. “There’s always the time zone challenge. If your design partner is in Australia, there are just a couple hours of business-day overlap,” David Hendee, partner and director of design at design firm Carbon Five, told Design News. “We have to fly people around to get the face-to-face communication.”

Face-to-face communication with the outside design team is particularly important when the relationship starts up. “It’s best if you can bring in people at the beginning to get them to know each other,” said Hendee. “We use a collaborative tool with visual communication while working on design projects, but prior to that, we lay the groundwork by getting people together.”

The Dangers of Outside Design on the Cheap

While using outside design support can deliver significant cost savings, those savings won’t necessarily materialize if it’s done on the cheap. “You want to deal only with solid companies with a good reputation in CAD design if you want to achieve your cost savings effectively,” said Munro.

He noted that companies trying to save as much as possible by simply outsourcing everything quickly find themselves in peril. “Outsourcing your whole brand, which has recently become more popular, is a sure kiss of death, especially if it is offshore,” said Munro.

One of the difficulties of turning design over to a distant untested firm is that the problems may not become apparent until it’s too late. “Oversight can be difficult, and outside teams may present data or reports that sound positive but are not accurate,” said Munro.

He noted that you risk your IP and brand, while opening yourself up to a load of potential environmental infractions, if you’re not careful. “Mega outsourcing to low-cost countries might as well mean handing over your ship and your cargo because you are too lazy to captain it,” said Munro.

Balancing Outside and In-house Design

How much of the design work gets handed over to the outside team varies from company to company. “Sometimes we’re the whole design department,” said Hendee. Other times, the outside team contributes just a portion of the design.

“We’ve worked with Fandango. They have in-house design, but we do design augmentation,” Hendee said. He also noted that it’s common for a company to bring in an outside team to revamp an existing product. “The product doesn’t always have a clear beginning and end, since products live on. When the client already has an in-house team, they’ll onboard us just for part of the work.”

Hendee noted that sometimes Carbon Five’s role is limited to a specific product rollout. “We’re seeing a lot of companies with legacy departments that include design and engineering,” said Hendee. “They don’t have strong cross-functional teams, so we come in with a kind of commando team to bring a product from a vision to market rapidly.”

He noted that once the period of rapid design is completed, the next step is to train the company to do rapid product design for themselves, including creating their own cross-functional teams. “They bring us in because they need to become more integrated in order to do the work themselves,” said Hendee.

IP and the Outside Team

When divvying up the design, companies need to be careful to keep their technology close to home. “A lot of companies have tried to offshore technical development while doing local design. They end up with technology they don’t know much about, and that can stifle innovation,” said Hendee.

IP is always an important issue when working with outside firms. “Our master services agreement spells out that the customer owns everything unless we specify certain codes that are ours,” said Hendee. He noted that he steers clear of sensitive client data.

“While we may work on data for infrastructure, we don’t have access to customer data. We have to be careful because we’re not in-house,” said Hendee. Even so, the design work can lead to new technology that becomes valuable IP. “We make it clear that whatever our team comes up with belongs to the client,” said Hendee. “We actually help our clients with their patent applications.”

Rob Spiegel has covered automation and control for 15 years, 12 of them for Design News. Other topics he has covered include supply chain technology, alternative energy, and cyber security. For 10 years he was owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like