Transient Plasma Ignition Promises 20 Percent Combustion Efficiency Gain

Even the already-efficient Toyota Dynamic Force Engine can benefit from new ignition technology.

As the internal combustion engine reaches its very mature twilight, it turns out that there may still be a surprisingly large efficiency improvement that is possible through transient plasma ignition.

Simulation by Sandia National Laboratories shows when an internal combustion engine is retuned to an ultra-lean-burn fuel mixture of greater than 30:1, an efficiency improvement of 20 percent is possible using nanosecond pulsed power ignition from Transient Plasma Ignition, Inc.

Engine consultants FEV North America tested an actual 2.5-liter Toyota Dynamic Force Engine using the transient plasma ignition system and minor calibration changes including increased exhaust gas recirculation (EGR) yielded an improvement of 6 percent to an already efficient engine.

Because transient plasma ignition is a plug-in replacement for traditional ignition systems, it works alongside gasoline direct injection, turbocharging, and hybrid-electric drive to wring out the most efficiency possible from combustion technology during the transition to electric vehicles.

“The world cannot transition to widespread electric vehicle adoption overnight, despite the ambition and commitments of automakers and legislators,” said Dan Singleton, CEO and co-founder of Transient Plasma Systems, Inc. “Hundreds of millions of internal combustion engine vehicles are projected to be sold around the globe in the next decade,” he continued. “There is an immediate need to produce cleaner gasoline engine vehicles to meet the global CO2 target and automakers recognize advanced ignition systems as a necessity to achieve the last great CO2 reduction.”

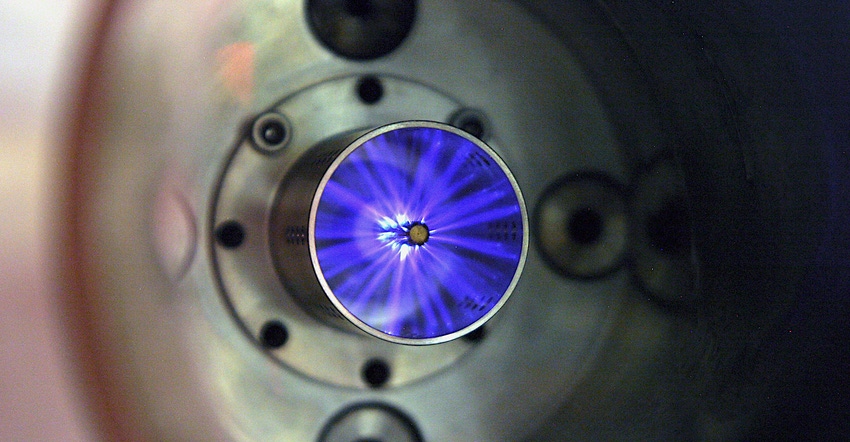

The transient plasma ignition employs very high power of more than 5 megawatts at very low energy of less than 100 millijoules to create a plasma that Ohio State University researchers found shortens ignition time by two orders of magnitude and reduces ignition temperatures by 540 degrees.

Faster ignition means the flame front has more time to spread throughout the combustion chamber ensuring more of the fuel mixture gets burned. The lower temperature means reduced formation of oxides of nitrogen (NOx) pollution and reduced waste heat.

With the benefits of the technology now proven, TPS is pursuing commercialization of its transient plasma ignition through partnerships with Tier 1 suppliers because those companies have experience manufacturing automotive products at a commercial scale, the company said.

About the Author(s)

You May Also Like