Stellantis Launches $85 Million Wind Tunnel Upgrade

The Chrysler parent company is adding a moving ground plane to its Michigan wind tunnel.

Automaker Stellantis is spending $85 million to upgrade its aerodynamic test facility at the company’s Auburn Hills, Michigan headquarters. This will include $29.5 million for the addition of a moving ground plane for its wind tunnel, which is crucial for accurately measuring aerodynamic forces on the cars being tested.

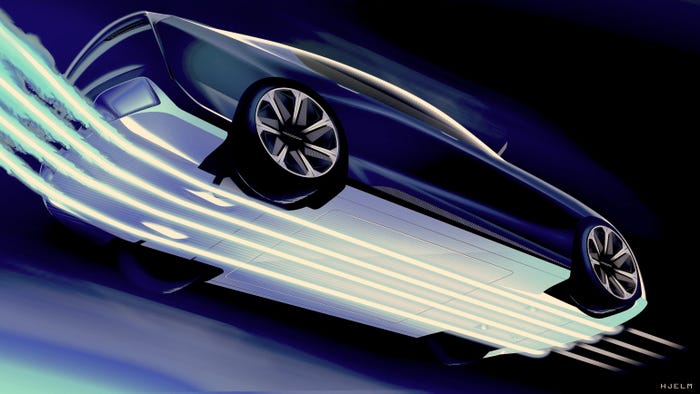

Battery-electric vehicles struggle with driving range because of the comparatively small amount of energy carried in their battery packs compared to that in a tank of gasoline, so efficiency is paramount in EVs to maximize the use of that energy. But when new EVs are boasting an efficiency of 95 percent for their electric drive systems (as is the case for Hyundai’s new E-GMP-based models) there is little efficiency left to be wrung from the drivetrain.

That leaves aerodynamic drag as a key area of potential gain, and automakers are addressing this with expanded wind tunnels, as we’ve seen from the new Honda Automotive Laboratories of Ohio wind tunnel. The new Stellantis moving ground plane facility joins two others within the company that are in Europe.

“Our world-class tech hubs across the globe are doing the work today that will make tomorrow’s Stellantis vehicles industry leaders in capability, performance, and safety,” said Harald Wester, Stellantis Chief Engineering Officer. “It gives us a comprehensive view of the challenges and enables us to consider and refine a full menu of mobility solutions that will put us in the front row of the race to innovate and improve.”

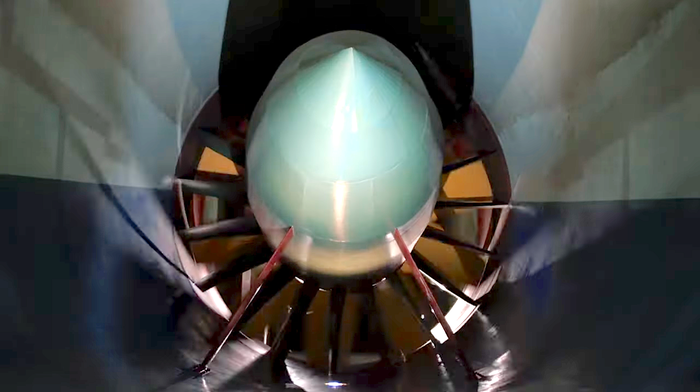

Construction on the installation of the moving ground plane is underway now at the Stellantis wind tunnel complex in Auburn Hills, Michigan. When it is complete, belts in the floor will enable wheel movement at all four corners of the vehicle while a wider fifth belt runs beneath the vehicle as if it were rolling over a roadway.

Significantly, moving ground plane technology permits the measurement of ventilation drag, which is the resistance associated exclusively with wheels and tires in motion. That accounts for as much as 10 percent of the total, real-world aerodynamic drag and it can’t be accounted for and minimized without such advanced wind tunnel technology.

The Stellantis tunnel runs at a maximum of 140 miles per hour, so unlike the new 192 mph Honda tunnel, it won’t get borrowed by racing engineers searching for more speed from the company’s race cars.

The update should be finished in 2024, though we’d have to guess that Stellantis is subject to the same supply chain constraints and the inclination of contractors to take off for deer season as any of the rest of us trying to get a home improvement project finished on time.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)