How to Build a Better Bilstein Shock Absorber

The new Ram 1500 TRX off-road beast exploits Bilstein’s new Black Hawk shocks for maximum performance.

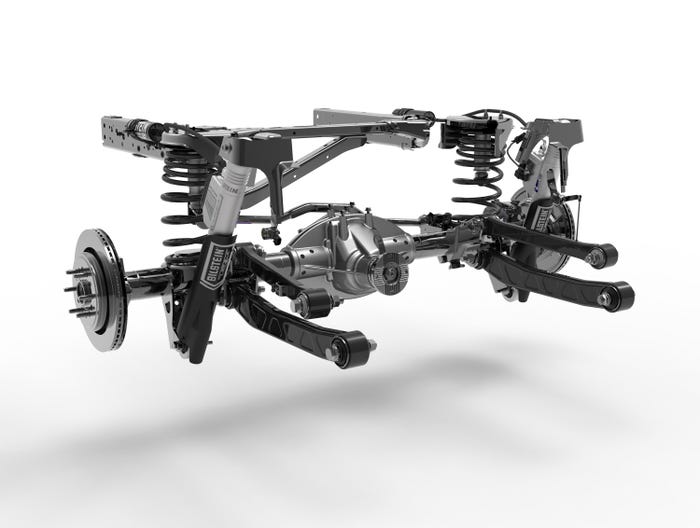

Ram’s new 1500 TRX is a technical tour de force for off-roading, and the shock absorbers provided by Bilstein are a key ingredient to the truck’s capability.

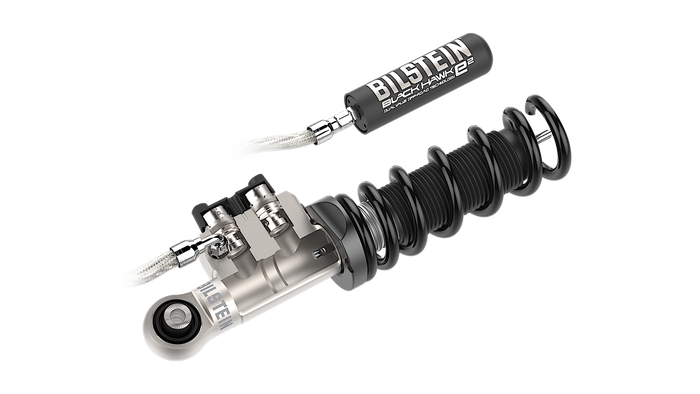

They are Bilstein Black Hawk e2 dampers with Active Terrain Dynamics, and we chatted with Bilstein’s manager of technology and innovation, Jason Engelman.

DN: What are the manufacturing challenges of building the shocks with this cool tech, especially compared to the regular shocks that might be on an ordinary Ram 1500?

JE: Developing a brand-new shock absorber to exceed RAM and SRT’s expectations was a challenge we gladly accepted. After discussing the performance goals that were delivered to us by the SRT Dynamics Team, we knew the design would come with many challenges, but none that we were not willing to take a stab at from an engineering perspective.

Perhaps one of the biggest manufacturing challenges has been the precision-machined single-piece aluminum body. Outwardly visible are the cooling fins that are directionally machined to align with airflow on the vehicle for more effective cooling, as well as porting for the nitrogen reservoirs and our dual electronic proportional valves, which are arguably the heart of support when it comes to the Active Terrain Dynamics system.

Obscured from view are additional challenges of tight tolerances and fine surface finishes inside the aluminum body—even deep inside the main bore, out of reach of typical tooling—for alignment and sealing necessary to ensure lasting performance.

This system created new damper architecture and with the new manufacturing method, it should be the model for all future damper assembly processes. All that said, the scale and construction methods of the Bilstein Black Hawk e2damper are like nothing else on the market, and the performance is unrivaled.

DN: Cost is surely a concern for a cool product like this, so how is Bilstein able to manage that to keep the customer happy while still delivering the performance?

JE: When it comes to working with an automotive OEM, we understand that cost is not an afterthought and should always be considered. However, given the groundbreaking TRX platform, performance and reliability were by far the key focus. Being the global leader in automotive shock absorbers and a subsidiary of a multinational conglomerate, Thyssenkrupp, we have the advantage of an incredible supply base.

DN: Are these shocks rebuildable? Why or why not?

JE: These shock absorbers are not intended to be rebuilt. Bilstein is well-known for quality shocks and the Black Hawk e2 is no exception. Considering the quality of components used, the rigorous testing to which these shock absorbers have been subjected, and the fact that every single shock absorber is performance tested prior to leaving the Bilstein plant in Hamilton, OH, Ram 1500 TRX owners can rest assured that they will stand up to off-road abuse.

Other shock manufactures recommended shock rebuilds every 1,000 miles when used off-road. Black Hawk e2 was designed for performance and longevity even with harsh off-road use and does not require the same maintenance.

DN: Can they be re-valved?

JE: As for valving, these shocks feature hydraulic valving and Bilstein algorithm modules that have been meticulously tuned specifically for a variety of TRX use cases. Where gas-pressurized shock absorbers are typically force-limited by the gas reservoir pressure in either compression or rebound, the internal hydraulic architecture of Bilstein Black Hawk e2dampers isolates the gas reservoir to allow an impressive range of damping force capability in both compression and rebound.

This means that the electronically controlled dual valve system has an extensive range of damping force capability at its disposal. The system provides independent damping force control for both compression and rebound shock absorber travel at each vehicle corner. A total of eight valves per vehicle are individually commanded by the proprietary Bilstein algorithm that monitors a variety of onboard sensors, continuously adjusting damping forces and prioritizing the control approach in order to achieve optimal body control and terrain isolation.

Our DT Sky Algorithm controls the dampers. We take data for steering, braking, acceleration, wheel position, body position (pitch, heave, roll) directly from the vehicle’s CAN bus. Our algorithm compiles this data and sends continuously varying levels of current to the rebound and compression circuits of each damper to achieve a desired behavior from the body…they are not simply hard, firm, soft discrete settings. The range of adjustment for the damper is so much larger than what is currently available.

DN: What aspect of these shocks are you most proud of?

JE: It is hard to pick one. I think if you ask each Bilsteiner on the Black Hawk e2 Team, they would each come up with a different feature or characteristic of the damper that sticks in their head or heart as a moment of pride. For me, it is the trust SRT had in Bilstein by intentionally selecting us as their partner for TRX and choosing to progress our relationship.

DN: What was the hardest challenge you had to overcome?

JE: Each step throughout the project presented different challenges. As the leader of the Acquisitions Team, my biggest challenge was to introduce and normalize the concept of “flying trucks” to our management team and our colleagues in Germany. Can you imagine explaining this? At Bilstein, the ACQ Team fields all OE customer requests. We review the customer’s project, decide what damper technology to apply (or, in some cases like the TRX, create a new technology from scratch), build the business case for the project, and release it to a Project Team to launch.

DN: Looking forward, what ideas did this project give them to work on for whatever the next product might be?

JE: We can’t talk about specifics but the performance capabilities of the Black Hawk e2 damper system have allowed us to look into markets that are not the typical automotive OE landscape.

About the Author(s)

You May Also Like