Honda Moves on from VTEC

Honda’s signature VTEC variable valve control system is heading for the sunset, as the company has introduced its first naturally aspirated V6 without it since the ‘90s NSX.

Variable Valve Timing and Lift Electronic Control (VTEC) has become Honda’s best-known technologies since Compound Vortex Controlled Combustion (CVCC) was in the 1970s. Coincidentally, while CVCC was an emissions control technology, VTEC is being phased out in favor of more conventional double overhead cam (DOHC) technology in pursuit of less pollution.

Honda’s non-turbocharged engines since the 1990s have employed single overhead camshafts featuring two sets of lobes. Hydraulically actuated rocker arms engine the milder, lower-lift, shorter-duration lobes during low-to-mid-RPM driving and switch to the high-lift, long-duration cam lobes at high revs. The engine’s unrestrained acceleration at the changeover is a popular aspect of VTEC’s success with enthusiast drivers.

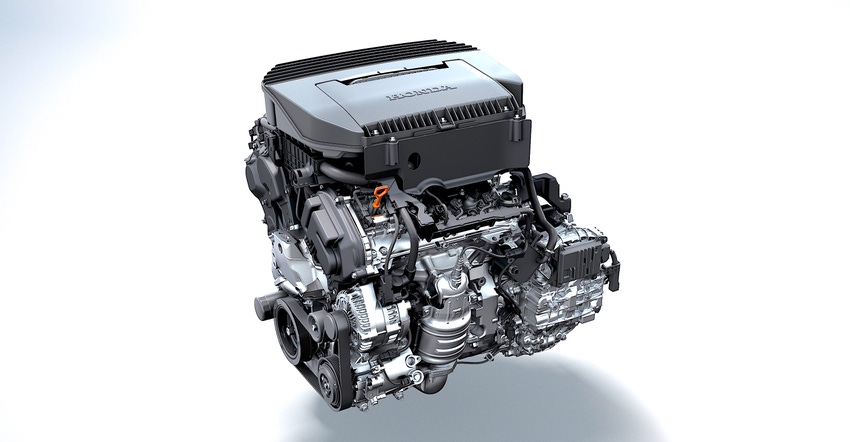

But the new 2023 Honda Pilot SUV has debuted an all-new 3.5-liter V6 engine that features a raft of improvements and the elimination of VTEC. The engine’s low-profile cylinder heads include high-tumble intake ports and a narrow 35-degree valve angle for improved combustion. The result is the most powerful US-market Honda V6, at 285 horsepower and 262 lb.-ft. of torque. The engine is built at the company’s auto plant in Lincoln, Alabama.

The new V6’s foundation is a die-cast aluminum block with cast-in-place iron cylinder liners. The thin-wall liners are made using a centrifugal spin-casting process and are high in strength and low in porosity. The deep-skit block incorporates four-bolt main bearing caps for rigid crankshaft support with minimal noise and vibration. The crankshaft is high-strength steel, also for minimal weight.

The engine includes a cooling control spacer positioned in the block’s water jacket surrounding the cylinders to help control warm-up and cylinder liner operating temperatures for reduced friction. Technicians plateau-hone the liners to further reduce friction between the piston skirts and the cylinder walls by creating a smoother surface. This is a 2-stage machining process that uses two grinding processes instead of the more conventional single-stage honing process. As an added benefit, plateau honing also reduces long-term engine wear.

Sliding inside those cylinders are new shallow-dish pistons designed to help maintain stable combustion and contribute to efficiency. They have a carefully optimized skirt design to minimize reciprocating mass to reduce vibration and increase efficiency. The piston rings are chrome-nitrided for reduced friction.

The engine is topped with new DOHC heads with four valves per cylinder. The heads are low-pressure cast using low-porosity aluminum with intake ports that induce tumble in the incoming air. This helps the mixing of the air and fuel for a more homogeneous combustion mixture for reduced exhaust emissions.

A new higher-pressure multistage direct-injection system provides the fuel. It features a compact, high-pressure, direct-injection pump that allows high fuel flow with variable pressure control to optimize injector operation. The injectors are a new multi-hole design that deliver fuel directly into each cylinder at 30 MPa of fuel pressure (up from 20 MPa) for more efficient combustion.

I look forward to driving the Pilot to see Honda’s progress in improving the performance of its direct injection under light-to-no throttle. The company’s current models toggle the fuel flow on and off during this light throttle tip-in while cruising at a steady state 25 mph which is annoying, so I’m hopeful for improvement with this new system.

Honda engineers shaved 1.2 inches from the engine’s height and reduced the part count by incorporating the head’s cam bearing caps directly into the cam cover. Engine height is important because of the need for space between the engine and the hood that provides room for the hood to crush in the event of a collision with a pedestrian. The switch to twin cams also contributes to more compact rocker arms and hydraulic lash adjusters, which also contribute to the reduction in engine height.

The changes to the V6 engine’s design compared to the outgoing Honda Pilot’s engine have contributed to a 40 percent reduction in smog-forming emissions like organic compounds and oxides of nitrogen, with a 50 percent reduction in unburned particulate matter. This results in an EPA LEV3 SULEV 30 rating.

The base price for a front-wheel-drive 2023 Honda Pilot LX is $37,295 and the starting price for a top-of-the-line all-wheel-drive Pilot Elite is $53,375.

About the Author(s)

You May Also Like