Bridgestone’s $100 Million Investment in Natural Rubber Hits the Track

Bridgestone’s cultivating an alternative source of tire rubber and has put it to the test in IndyCar.

Today, more than 90 percent of the world’s natural rubber supply is extracted from the Para rubber tree, which primarily grows in Southeast Asia. In 2012, Bridgestone launched a bid to help diversify the supply of natural rubber with a program to develop a plant called guayule (WHY-U-LEE), and a decade later the company has made tires using that rubber for the IndyCar race in Nashville, Tenn.

Specifically, the guayule natural rubber was used in the Firestone Firehawk’s sidewall, because that area is made up of the most natural rubber. This preserves the same quality and performance as the existing race tires. These tires debuted wearing green sidewall lettering to indicate that they are something special, even though their performance should ideally be indistinguishable from the company’s other tires.

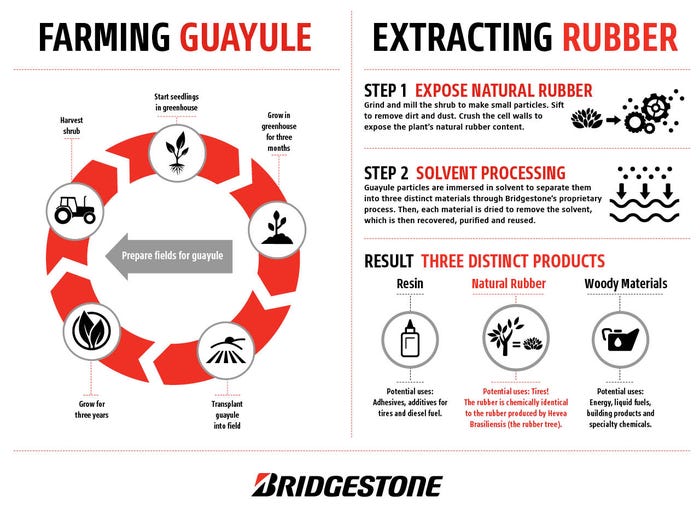

Guayule is a drought-resistant, heat-tolerant woody desert shrub native to northern Mexico and the southwestern United States. Natural rubber comes from the branches, bark, and roots of the shrub. The natural rubber extracted from guayule cells is chemically identical to the rubber traditionally harvested from Hevea Brasiliensis rubber trees.

Bridgestone says that guayule is part of a plan to achieve carbon neutrality and make tires from 100 percent renewable materials by 2050. Just as importantly, guayule can be cultivated using minimal water, so it can be farmed in arid southwestern U.S. states while using less water than other commercial crops currently grown there.

Guayule is not currently a commercial crop, so Bridgestone has spent $100 million developing the ability to produce the seed and grow the crop. Importantly, guayule doesn’t compete with traditional food source crops, instead using a grower’s existing row crop equipment to save costs.

It has been a lengthy process to reach the point of building the racing tires using rubber from this process, and the next step will be making production tires for customers’ street cars. That will require a big step in guayule farming and production, but Bridgestone has shown it has the commitment to see the material through to production.

Debuting in the IndyCar series is a great opportunity for the company to showcase the rubber’s potential. “The introduction of guayule natural rubber to America’s preeminent open-wheel racing series speaks to the confidence we have in the technology and its potential as a scalable, sustainable, and domestic source of natural rubber – a vital raw material," said Nizar TriguiChief Technology Officer and Group President, Solutions Businesses, Bridgestone Americas, Inc. “It will take partnership and collaboration to combat the impacts of global climate change and we are proud to partner with Penske, INDYCAR, and IMS to advance the future of sustainable mobility.”

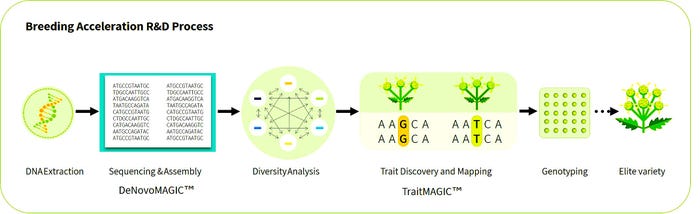

This hard work, which earned a U.S. Dept. of Energy grant along the way, started with a partnership with genomic big data solutions company NRGene to analyze the plant’s DNA to breed highly productive varieties of guayule.

Using NRGene’s DeNovoMAGIC system, scientists at Bridgestone and NRGene assembled a specific guayule genome that provided a complete description of the genome sequence and all its genes. This let researchers exploit guayule’s genomic diversity to identify the genetic source for important traits such as rubber percentage.

Then, Bridgestone developed mapping populations that let NRGene construct a genetic and physical map by successfully identifying the correct order of DNA fragments. These maps guide researchers through the information contained in the genetic code to assist in breeding efforts. The joint work constructed pseudochromosomes (molecules that contain most of the information of the chromosomes) using an approach that combines multiple genomes.

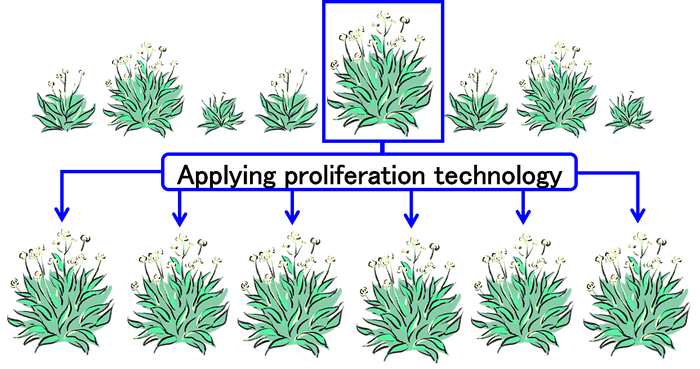

Once Bridgestone had created a productive guayule variety, the company had to farm it. For that, the company partnered with Kirin Holdings Company to deliver large-scale propagation of guayule plants from high-quality seeds.

Bridgestone grew the resulting seeds on its 287-acre Agro Operations Research Farm in Eloy, Ariz. starting in 2021. Now, they’ve extracted enough natural rubber from plants grown on that farm to start making tires for the IndyCar series.

When farmers harvest guayule, the next step is to grind the shrub into particles, sifting through that to remove dirt and dust. Then they crush the remaining ground material to expose the plant’s natural rubber content.

Guayule growing at Bridgestone's 287-acre Agro Operations Research Farm in Eloy, Ariz.

These crushed guayule particles go into a solvent tank to separate them into their constituent resin, rubber, and woody material components. The resin can be used as an additive for tires or diesel fuel, or as an adhesive. The woody material can be burned for energy or used in building products. And the rubber can be used in tires because it is just like Hevea Brasiliensis rubber.

Bridgestone says that by 2030 this process will be ironed out sufficiently for commercial use in tires for regular customers. Until then, the IndyCar drivers will be able to enjoy the fruits of the labor of so many researchers in a variety of fields to make this possibility a reality.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)