Bosch Targets Fuel Cell Platinum for Recycling

Bosch aims to bring fuel cell platinum into the circular economy with the batteries the company already recycles.

It isn’t only the enterprising people helping themselves to the catalytic converters in parked cars who seek to recycle valuable platinum. Bosch wants to recover platinum the legal way rather than cutting it out from underneath other people’s cars.

The goal is to recycle the platinum that goes into hydrogen fuel cells when the cells reach the end of their useful lives. It can be reused in new fuel cells or be used for other applications such as new catalytic converters. Bosch estimates that it can recover 95 percent of the platinum that goes into its fuel cells.

Q&A With Bosch President on the Migration to EVs

According to derivatives marketplace CME Group, Inc., recycled platinum currently accounts for about 25 percent of the industry's supply, with 80 percent of that total coming from automotive catalysts. Most of the rest comes from recycled jewelry.

To recover the platinum, Bosch has inked a deal with Cologne-based mobility startup Hylane, which provides for the repurchase of fuel-cell stacks by Bosch after their useful lives in the hydrogen trucks Hylane leases.

The deal guarantees Bosch an option to repurchase stacks, which will be recycled by a third-party company. Hylene’s benefit is that Bosch will use the recovered platinum in fuel cells destined for use in Hylane’s trucks.

“We’re proud to have reached this innovative model agreement with Bosch that gives it the option to repurchase retired fuel-cell stacks,” said Hylane managing director, Sara Schiffer. “To achieve a sustainable transformation in mobility, it’s important that we consider not only vehicle use on the roads but the entire vehicle lifecycle as well.”

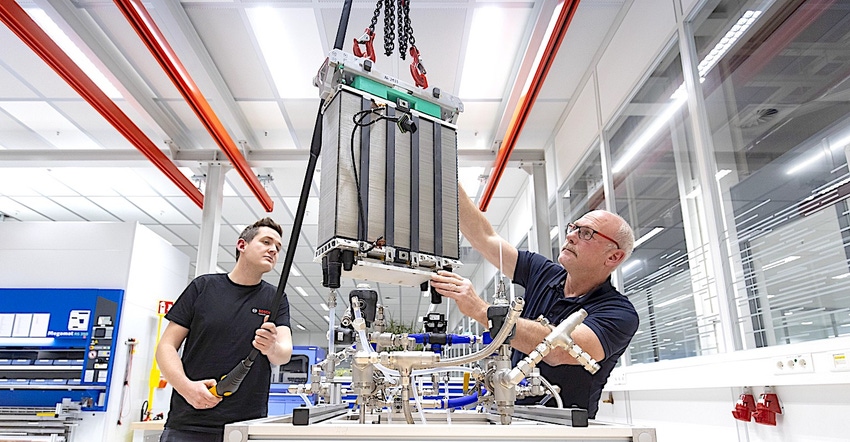

Bosch Initiates Fuel Cell Production for Commercial Trucks

As it does in catalytic converters, platinum acts as a catalyst in the fuel cell. In this case, it accelerates the reaction of hydrogen and oxygen rather than oxidizing unburned hydrocarbons.

The precious metal is $938 an ounce at the time of this article’s writing. For comparison, gold is $1,932 and palladium, which is also used in catalytic converters, is $1,250. Silver is a bargain at $23. Global demand for platinum will grow by 20 percent by 2040, according to a 2021 study by the German Mineral Resources Agency, so recycling will help keep a lid on price increases.

Additionally, recycling platinum will help Bosch cap the carbon footprint of its fuel cell production. In that process, platinum accounts for 80 percent of the carbon emissions, Bosch says.

“By recycling, we can make the stacks more economical and at the same time reduce the carbon emissions associated with platinum mining,” said Thomas Pauer, the president of the Bosch Powertrain Solutions division. “We’re already laying the groundwork for recovering rare raw materials like platinum."

"Our estimates suggest that by 2030 at the latest, appreciable numbers of fuel cells will need recycling,” Pauer continued. This seven-year span from now compares to an average 13-year lifespan for catalytic converters before they are recycled, according to the CME Group.

When they do, it will both save money and reduce the CO2 emissions associated with the manufacturing of future fuel cells. “By recycling, we can make the stacks more economical and at the same time reduce the carbon emissions associated with platinum mining,” Pauer said.

How Honda Outsmarted Catalytic Converters

Bosch points out that as part of its Bosch eXchange program, the company’s Automotive Aftermarket division has been reconditioning parts such as used starter and alternator units for decades, which is an even more efficient form of recycling.

About the Author(s)

You May Also Like