A crystal-ball look into the issues facing manufacturers in 2023 reveals the need to improve the use of data while solving thorny staffing and sustainability challenges.

November 21, 2022

Manufacturers face lingering post-COVID issues as 2022 comes to a close. The effective use of data – from track-and-trace through predictive maintenance – is becoming imperative. Many manufacturers are turning to service-based solutions to optimize production.

Employment issues are also increasing, from The Great Resignation to the million-plus shortage of manufacturing workers. The need to face sustainability is increasing are manufacturers feel the pressure to reduce their carbon footprints.

We turned to Doug Lawson, CEO of ThinkIQ, to learn about the issues manufacturers will face in 2023. Lawson sat down virtually with Design News to offer these predictions for the coming year.

Prediction #1: The dawning of the IoT ‘as-a-service’ revolution and the demand for predictive maintenance

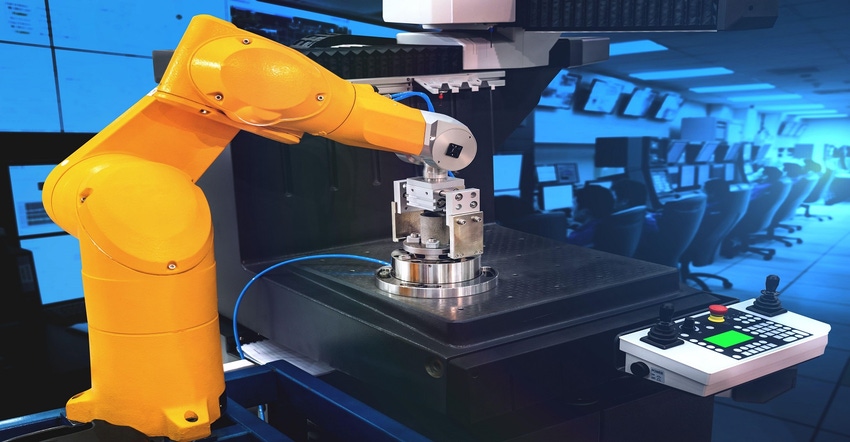

IoT is driving the ‘as-a-service’ revolution. Service providers are realizing the benefits of subscription service models using products and machines that have built-in sensors, so that the owner can track the life of the product and conduct repairs and maintenance when necessary, allowing the manufacturer to focus on optimizing the efficiency of supply chains. IoT has enabled manufacturers to make informed, strategic decisions using real-time data and achieve a wide variety of goals, including cost reduction, enhanced efficiency, improved safety, product innovation, and more. We expect to see these trends continue to accelerate into the new year and beyond as IoT devices increase.

Prediction #2: Data reigns supreme

Big data is helping the manufacturing industry to attain full automation of operations. Further, with the expansion of the internet of things and advancement in connectivity technologies, big data is offering an opportunity for a new breed of intelligent manufacturing technology.

Statista predicts that the big data business world is going to be worth $77 billion by 2023. Big data is becoming the new currency in manufacturing with renewed interest in IoT and the ability to collect comprehensive data from IoT devices equipped with sensors on the shop floor. This valuable data provides them with a comprehensive understanding of their business — and is essential as they work to reevaluate their forecasting and planning models. After all, with the proliferation of devices on the shop floor, manufacturers have even more data to sift through.

Prediction #3: Manufacturers will increasingly embrace traceability to achieve sustainability goals

An increasingly volatile global economy is putting pressure on manufacturing leadership teams to improve the sustainability, performance, and resilience of their operations. As this pressure grows, manufacturers are looking to increase traceability across operations for improved sustainability, productivity, and transparency in their supply chains. By increasing sustainability in the supply chain, manufacturers can be a part of the drive toward a greener future, while reducing waste and operational costs.

While many manufacturers are still effectively blind to a staggering percentage of events on the factory floor and in their supply chains, we expect that the increase in black swan events and economic disruption will finally force them to increase their focus on improving traceability to meet their sustainability goals and weather the economic storm. As a result, ESG will become more fully integrated and measured by business systems.

Prediction #4: Employee safety remains a top priority

Workplace safety has always been a priority for manufacturers and took on a new significance during the pandemic. In addition to basic safety precautions, such as enforcing social distancing measures on the production floor and ensuring that workers sanitize their workspace, manufacturers must closely and carefully monitor who enters and exits their facilities, and which individuals or equipment they interact with. This has led many manufacturers to in-source facility maintenance and management and placed increased emphasis on traceability and vision technology.

We predict that this trend will have a direct effect on supply chain visibility, as manufacturers demand greater transparency from suppliers as they work to track issues and claims throughout the manufacturing process.

Prediction #5: The Great Resignation and transfer of knowledge

A joint report by Deloitte and the Manufacturing Institute estimates that 2.7 million jobs will be lost over the next few years due to attrition and retirements. Given this backdrop of economic uncertainty, organizations have been forced to adapt. Many veterans that have learned valuable hands-on skills over the years and become the lifeblood of the shop floor are beginning to retire, resulting in quick turnover and new talent. This presents the challenge of how organizations will efficiently transfer tribal knowledge from retired veterans to new, younger, and differently skilled employees. As the supply of qualified employees remains low, the demand for formalizing this business knowledge into business systems will rise. Organizations will require solutions to institutionalize knowledge in a way that is optimized in a business process. Smart manufacturing software is urgently required that facilitates data on demand and integrates end-to-end digital operations.

About the Author(s)

You May Also Like