Crush This Laptop and it Still Works. Welcome to Military Toughbook Devices

After 25 years of creating computers for the military, Panasonic has learned the art of introducing new features while keeping existing devices in service.

June 22, 2021

Military computers have to meet the highest performance specifications while also being incredibly durable. As a result, these ruggedized computers have to be able to withstand punishment that is rarely seen in the civilian world. That can go from extreme heat to frigid cold to slams to the ground.

Panasonic creates products for the military that utilize industrial components while including an added level of ruggedization. “When we work on product development, we try to balance the needs of a variety of industries and customer sizes. Customer input into our product development has been a piece of our DNA since we first started selling Toughbook computers 25 years ago,” Anthony Mungiello, Toughbook senior product manager at Panasonic, told Design News. “We work with the military on a wide range of projects that encompass several high volumes projects which are rolled out over several years.”

Off-the-Shelf Components?

To keep costs down, ruggedized products often include consumer off-the-shelf components. Mungiello noted that Panasonic avoids standard consumer components since they are not likely to hold up to the rigors of military use. “As a general rule, we use industrial-grade components that cost more than consumer-grade components yet are tested and engineered to last longer, survive harsher environments, and have longer life procurement cycles,” said Mungiello.

As well as creating industrial-use parts, Panasonic also includes ports that have vanished from consumer devices but are still in use in the military. “Several projects require specialized ports that are not common in the consumer market anymore but are still used in the military. Users may need to interface with equipment purchased a couple of decades ago, said Mungiello. “We are one of the few PC companies that do our manufacturing, even making some of the industrial robots that build our machines.”

Taking the Slams of Military Use

Devices created for the military are designed to withstand extreme shock as well as wild temperature variations. That also includes the need for water and dust protection. “As a baseline, all Toughbook devices have fully rugged products that can be used in extreme environments whether, in deserts, mountains, torrential rain, snowstorms, sand storms, blizzards, or hurricanes,” said Mungiello. “These products must support our customers completing their mission-critical work wherever they may find themselves. That’s especially true for the military who can be anywhere in the world and whose own life and those around them, could hang in the balance upon successfully using their Toughbook device.”

Security is also a component of ruggedization. That has to be included in eh design process. “For security, some projects require Wi-Fi, Bluetooth, and camera components to be physically removed or disabled in the BIOS. Other projects could have unique color requirements for the outside of the device for camouflage and stealth,” said Mungiello. “Displays are needed that can be viewed in all conditions, whether in direct sunlight or when paired with a night vision filter and goggles. Our secret sauce is how to maintain that high performance in extreme conditions including high temperatures.”

Working with the Military on Device Design

Part of the process of creating tools for the military involves gaining approval on designs before production. “Designs have to meet specs not only in terms of fit, form, and function but also with rugged specs. The customer – the military – ultimately approves of a design when they purchase it,” said Mungiello. “To ensure the product has the right fit, we work closely with key customers during development to try to bake in customer requirements.”

As part of the design process for military equipment, Panasonic creates products that can last longer than the typical consumer device. “Most of our customers keep our devices for approximately five years, so we must stand behind our products for that entire time and offer specs and features that will futureproof their purchase for the duration,” said. Mungiello.

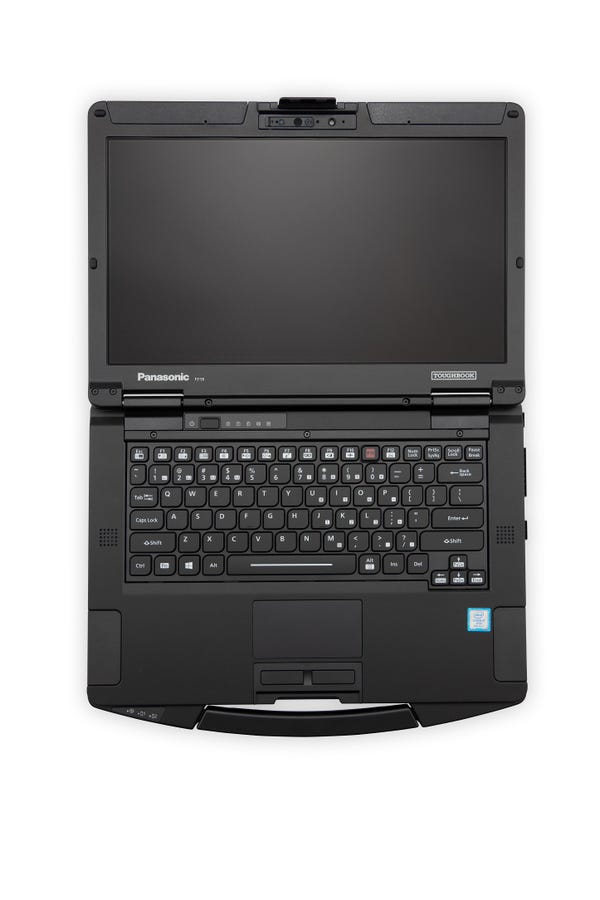

Also in the design process, Panasonic includes representatives from the military. “We gather customer input in a wide variety of ways including advisory councils, visits, and surveys. Our Toughbook 55 has a truly modular design that has six modular areas that allow customers to purchase these items later to upgrade their device as needed,” said Mungiello. “It also allows them to simplify their purchase by ordering one base SKU and purchase the different accessories as needed for their users. The RAM and SSD, and the keyboard user-replaceable.”

The Long Lifecycle Curve of Military Equipment

Products in the military have to be designed to last significantly longer than consumer products. That’s true in all aspects of performance. Even as new products are introduced, they are created to be backward compatible. “Testing and procurement lead times for the military tend to take longer, and since even a minor change could require the unit to be fully retested, contracts typically require a specific product down to the ordering SKU stays the same for long periods,” said Mungiello. “During the lifecycle of a unit, we stay close to our customers to make sure they don’t get caught in an endless cycle of testing, obtaining procurement approval, deploying, and then repeating the cycle. We also overlap it with a new version to ensure customers have enough time to test the new version, while still being able to purchase their old model.”

Rob Spiegel has covered manufacturing for 19 years, 17 of them for Design News. Other topics he has covered include automation, supply chain technology, alternative energy, and cybersecurity. For 10 years, he was the owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like