Lighten Up Your Composite & Multimaterial Assemblies

June 29, 2016

A new fixings and fastening system for assembling structural, load-bearing composite components promises 54% better adhesion, plus less weight and better mechanical performance than current composite fixing designs.

After five years of R&D, UK-based engineering and design company Adhesion Technologies Ltd. launched its new Spida Fixings and fastening system, combining fasteners with adhesives. It was designed to give OEMs and their Tier 1 suppliers in aerospace, transportation, and automotive industries a cost-effective system for fast assembly of composite, engineering plastic, and metal parts, using either metallic or non-metallic fixings.

According to a press release sent to Design News, Adhesion Technologies' Spida Fixings and fastening system was designed by composites engineers. This contrasts with the more common approach, which is to task mechanical engineers with designing fastening systems. It combines a unique base design with a proprietary adhesion technique that forms a high-strength bond to a broad range of substrate materials.

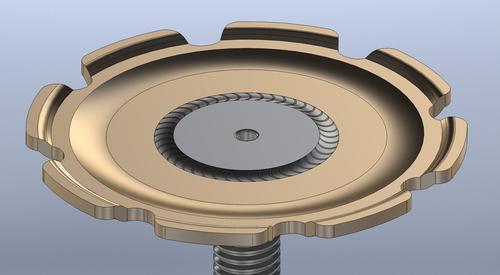

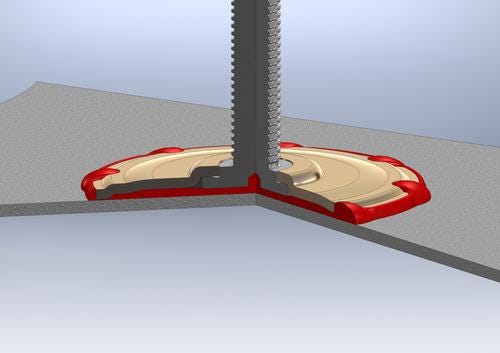

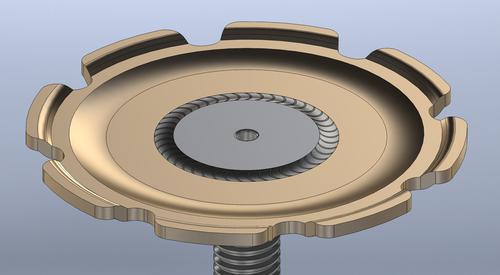

Each Spida base includes a large bearing area for attachments, plus a positive landing area that prevents adhesive from being squeezed out from underneath the fixing. Bases also have a concave shape that forms a "micro chamber" for the adhesive, which lets its long-chain molecule structure orient from 0 to 180 degrees during curing. This results in enhanced peel, shear, torsion, cleavage, tension, and compressive loading. For example, by forming lugs in the adhesive, the castellated edge design of the Grippa base fixing option delivers 24% greater torsional resistance strength than circular fixings.

READ MORE ARTICLES ON FASTENING & JOINING:

All Spida bases are also equipped with Adhesion Technologies' surface enhancement treatment technology on the bond interface. By spreading stress across a larger area of the substrate material -- the classic advantage of adhesives, compared to fasteners used alone in point solutions -- the Spida system lets design engineers specify a smaller diameter of fixing for the same level of performance by the part when it's in use. Because of premature fixing failures, OEMs often specify larger fixings than are actually needed in a composite design. That's because, according to the company's extensive comparative testing, many current composite fixing designs can fail prematurely before the metallic stud's ISO-specified breaking point is reached.

Specifying smaller-diameter fixings helps reduce weight and costs. Because the system actively redistributes cluster stress loads in the substrate it's affixed to, it also significantly reduces stress levels in the immediate fixing area, improving mechanical performance. The overall result is up to 54% more adhesion performance, according to test data from independent test houses.

Two metal fixings options are cold-headed, high-strength manganese boron (20MnB4) steel alloy fixings with deep draw (CR4) manganese steel bases, or marine-grade molybdenum alloyed 316L austenitic stainless-steel fixings and bases. Both were developed for fastening composite components in land transportation and marine applications. Also available are exceptionally lightweight non-metallic fixings in two versions: a tough, general-purpose, glass fiber-filled polyamide 6, or a higher-performance, carbon fiber-filled polyetherimide thermoplastic composite.

The first of five different solutions, Spida Studs, is now available, in standard diameters of M4 to M12, and in lengths from 20 mm to 60 mm, with matching bases and threaded blind or through standoffs. Spida studs, threaded standoffs, and bases can be used either alone or together as a welded fixing.

Ann R. Thryft is senior technical editor, materials & assembly, for Design News. She's been writing about manufacturing- and electronics-related technologies for 28 years, covering manufacturing materials & processes, alternative energy, machine vision, and all kinds of communications.

About the Author(s)

You May Also Like