Formlabs worked with Louisville Slugger to take the baseball bat into the future.

April 16, 2023

Louisville Slugger created a new spin on the baseball bat at the Slugger Innovation Center in Roseville, Calif. The company's product designer John Steel used a combination of traditional and modern tools for the design and manufacturing of aluminum and composite baseball bats. Engineers used Formlabs’ Form 3 printers to advance equipment design, resulting in the BBCOR Atlas.

In creating the BBCOR Atlas, Louisville Slugger engineers merged traditional manufacturing methods like CNC milling, lathes, and wood patterning with 3D printing to make their bat manufacturing process significantly faster. The process reduced the long wait times between outsourced iterations.

While these bats don’t meet the stringent requirements of Major League Baseball, the bats can be used by youth and collegiate players around the world.

A Story Told in Photos

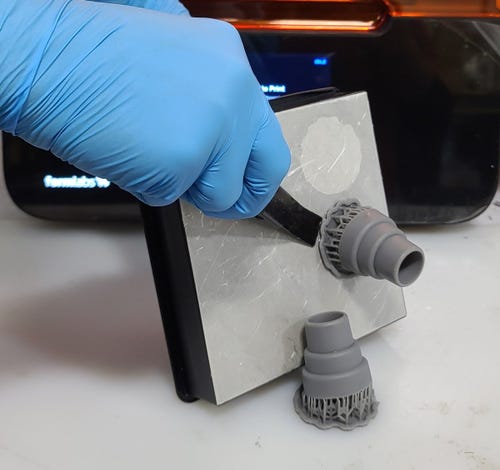

In the photo below, Steel removes a prototype of the Pyramid Grip component that will be used as a mold positive. The mold will then be back poured with another material like silicone or urethane.

Here, light-touch supports make post-processing faster and easier, with less mess.

Using a 3D printed master, Steel poured silicone to create tooling for a prototype of the Pyramid Grip.

After the silicone mold is created, Steel can inject another material like urethane or epoxy to create the finished prototype.

3D printing helped Louisville Slugger speed up the iterative process with innovation from concept design (light grey, 3D printed part, far left) to the finished part made with traditional manufacturing (pink part, far right).

About the Author(s)

You May Also Like