Origami Inspires Cutting, 3D-Printing Technique for Complex Glass Shapes

A multi-step process uses a composite material and strategic heating to achieve stable objects through 3D printing.

May 3, 2023

A modern update to how the ancient paper arts of origami and kirigami are used is helping scientists develop intricate shapes in glass and other hard materials using 3D printing, researchers said.

A graduate student in the lab of Principal Investigator and Professor Tao Xie from China's Zhejiang University developed a 3D printing method that allows for the production of complex shapes with hard materials like glass using a process that involves exposing it to strategic heating through ultraviolet light, sintering, and other processes.

Along the way, the material—a composite of polymer and silica, the main ingredient for glass-making—is cut and folded using kirigami and origami principles, the researchers said.

Yang Xu, a graduate student at Zhejiang University, and the team chose to cherry pick the best characteristics of these two paper arts to allow them to produce more complex shapes with materials with which it's historically been difficult to do so.

“When you fold a piece of paper, the level of complexity is somewhat limited, and 3D printing is kind of slow,” Xie says. “So we wanted to see if we could combine these two techniques to take advantage of their attractive attributes. That would give us the freedom to make almost any shaped part.”

The 3D Printing Process and More

The research builds on earlier work in which the team used origami and kirigami to shape soft materials made of polymers. However, they wanted to apply these techniques to glass and ceramic materials, “which are much harder to process into complex shapes than polymers,” Xie explained.

Typically, scientists use a mold to shape glass and ceramics, which can be 3D-printed into a final structure but typically not into a complicated shape, the researchers said. Even when printing is used to fabricate something more complex, it's a slow process and the resulting object can need extra support while it's made to maintain a strong structure.

Another shortcoming to 3D-printing these materials is that the final object tends to have a layered structure that might not be the desired appearance that designers want for the object, the researchers said.

To overcome these current challenges, Xu invented a technique in which she mixed nanoparticles of silica—the main ingedient for making glass—into a liquid containing several compounds. She then cured the mixture with ultraviolet light, which produced a cross-linked polycaprolactone polymer with mechanical properties similar to paper in which tiny beads of silica were suspended.

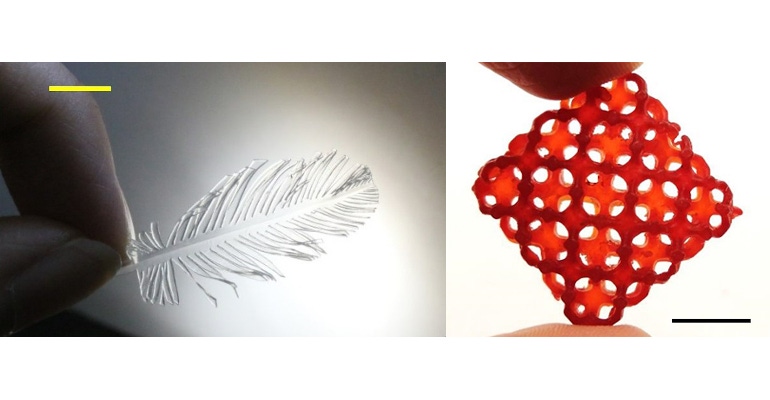

In the next step of the process, Xu employed the origami techniques by folding, twisting, and pulling on sheets of the translucent polymer composite to make a crane, a feather, a lacy vase, and a sphere made of intertwined ribbons, among other objects. Doing this at room temperature resulted in the composite retaining its new shape fairly well until the end of production, unlike some other 3D-printing processes for ceramic and glass materials, the researchers reported.

Why It Works

The researchers discovered throughout their work that it's the folding and stretching process that is integral to their success, they said. This is because it irreversibly disrupts the interface between some of the silica particles and the polymer matrix.

However, the material not only needs this process to retain its shape in the end, but the folding and stretching must be done while it's heated at about 265 degrees Fahrenheit (F), Xu discovered. It's this heating that permanently rearranges the links between the polymer chains, firmly fixing the new shape in place, she said.

Moreover, to create the final glass object, the researchers must heat the object again at more than 1,100 degrees F to remove polycaprolactone polymer from the object, which turns it opaque. Then, once it cools, scientists sinter the object to melt the silica particles together at temperatures topping 2,300 F, which converts the object into clear glass with a smooth, non-layered texture.

This final step was not without its challenges, however, as Xu had to find the right balance of polymer and silica to successfully achieve the clear glass object, she said.

Next Steps

Xu already is continuing the research by extending her method beyond glass to ceramics by replacing the silica with substances such as zirconium dioxide and titanium dioxide, she said. These compounds pave the way for producing “functional” objects, such as materials that are less fragile than glass or that have catalytic properties, the researchers said.

The group is also experimenting with a combination of kirigami and 3D printing to make even more complex shapes and is eyeing Xu's method for use in 3D printing to make ceramic structures perforated with microscopic channels, the researchers said. In fact, as a test case for the latter, the researchers already printed a pierced 3D lattice made of the silica-polymer composite, they said.

Ceramics and artists also can learn the work and apply it in catalyst and sculpture design, as well expand its use for other purposes, the researchers added.

About the Author(s)

You May Also Like