How to Build a Better Flexible Plastic Prototype Using 3DP

3D printing is an effective way to speed time-to-market while saving on development costs for flexible plastic products.

January 5, 2023

Speed and cost are essential considerations in product development. 3D printing has become increasingly useful as a way to produce prototypes under the dual pressures of time and money. We interviewed Fred Kaplan, Western US sales manager of Additive at Arburg, Inc., to get his view of efficient and effective development of flexible prototypes.

Arburg is a German company that manufactures plastic processing machines. The company uses industrial additive manufacturing and robotic systems to provide customer and industry-specific turnkey solutions.

Design News: Using 3D printing for prototypes has become commonplace in the product design life cycle, would you agree?

Fred Kaplan: Definitely! Manufacturers are doing everything they possibly can to speed up design cycles. We are in a market now where products need to make it to market as quickly as possible. Venture capitalists are counting on that, so additive manufacturing of prototypes has become essential, and pretty much everyone is doing it. The alternative would be injection molding or some other production-scale process and, even with aluminum prototype tools, this can be extremely time-consuming and expensive. For example, we talked to a company that was spending $50,000 to make seven variations of a new-product prototype using injection-molding tooling. We estimated that switching to additive manufacturing would save 90% of those development costs. So, not only does additive manufacturing speed up development, but it is also very cost-effective.

DN: When companies are tasked with creating prototypes for flexible components, what are their options?

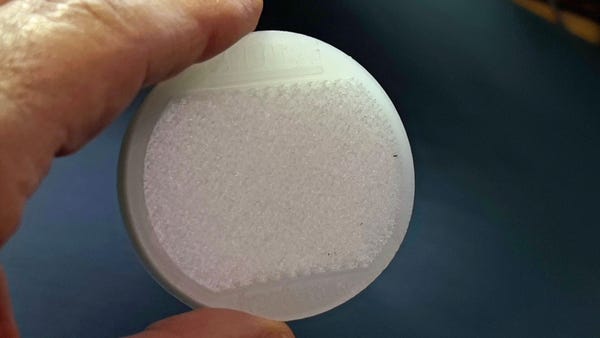

Fred Kaplan: There is a clear trend toward the increased use of flexible materials -- I should refer to them as elastomers – both in mono-material products such as seals, gaskets, flexible connectors, and the like (see Figure 1), and especially in dual- or multi-material applications where one part of the product is rigid and other parts are flexible. A good example of this would be a computer mouse in which the sections where the user would grip the mouse might be a soft-touch or elastomeric material over-molded onto a main body made of rigid plastic. Of course, there is always the option to use standard prototyping processes, but the cost and time constraints we talked about will apply, so additive manufacturing is usually a better choice.

DN: Do commonly available 3D printing solutions offer a successful path for flexible or partially flexible prototypes?

Fred Kaplan: Yes. Fused Filament Fabrication or FFF additive processes can use filament feedstock that is available in elastomeric compounds… most commonly thermoplastic polyurethane (TPU) and TPE, a generic designation for a flexible and rubber-like thermoplastic material. There are other, more exotic elastomer filaments available, but they can be difficult to use and quite expensive. In general, there is not a lot of variety in the polymers available or in the range of flexibility that is possible. In other words, there is a limit to how flexible the part will or won’t be once printed. And then, elastomeric filaments tend to produce parts that are susceptible to cracking or delamination when they are bent, which can limit the usefulness of the prototypes. So, for the most part, a 3D-printed prototype would not accurately represent the form, fit, and function of what will eventually be an injection-molded part.

DN: Is there a better solution that designers may not be aware of?

Fred Kaplan: Yes. Arburg has an additive manufacturing technology we refer to as Arburg Plastic Freeforming or APF. The company is primarily a manufacturer of injection-molding machines, and, unlike FFF printing techniques, this additive process is based on the same kind of barrel/screw plasticating mechanism used in injection molding. Instead of a filament, the Freeformer machine (see Figure 2) uses the same pelletized material as injection-molding machines. And, while FFF printers form a part with linear rows of melted plastic, APF parts are created by a series of overlapping spherical droplets approximately 200 microns in circumference.

DN: What are some of the advantages of thermoplastic pellet-based 3D printing for flexible materials?

Fred Kaplan: First, because a Freeformer can print the most commercially available injection-molding pellets, prototypers can consider any of tens of thousands of thermoplastics from the world’s leading material manufacturers… including elastomers. There are other benefits, which I’ll get to in a minute, but it is worth noting that commercial molding pellets are less costly than proprietary filament. I recently looked at ABS prices and some filament was as much as 35 times more expensive than pellets. Arburg has already qualified over a hundred resin grades but there is a chance that some materials will not be suitable for the APF process, and a material trial is required to qualify untested grades. Still, product developers have access to a much wider variety of materials to make additive prototypes, including, potentially, the exact resin grade that will be used to make the final article. In the mouse application I mentioned previously, for instance, the feel of a grippy elastomer would not simply be like the real thing, it could actually be the real thing.

A second important advantage of Freeforming is the fact that the process allows for the density of the droplets being deposited – the number of droplets per cubic inch – to be varied very easily. This makes it possible to create different levels of softness with one flexible material or in different sections of the same prototype (See Figure 3). In addition, some Freeformer machines can be equipped with up to three print nozzles. So, again using the mouse example, the housing could be made of a rigid material, while the grippy parts are formed from a flexible material such as a TPU, creating a rigid/flexible prototype in one simple operation. If needed, the third plasticating unit can deliver Freeformer’s proprietary water-soluble support materials, which are easily removed in warm water and a little agitation. This allows for making otherwise-unsupported structures… again, in a single operation.

DN: Based on how you see the technology evolving, what can people expect to see in the future?

Fred Kaplan: Obviously, there will be advances in additive technology and the capabilities of the Arburg Plastic Freeforming process. I think new developments are most likely to appear in the area of materials improvements, including the introduction of entirely new polymers and alloys. Regardless, the advantages of APF versus FFF are always likely to remain. Imagine, for instance, being able to create fully functional prototypes using new FDA-approved, implantable or bioresorbable materials – whether flexible or rigid – using production-ready materials. The Freeformer is now the world’s most versatile tool for fully functional prototyping and low-volume production. I’m sure we’ll see a lot of new things in the coming years, but I don’t think that will change.

About the Author(s)

You May Also Like

.jpg?width=300&auto=webp&quality=80&disable=upscale)